An optical fiber microsphere cavity mode-locked laser based on graphene channel structure

A graphene channel and mode-locked laser technology, which is applied in the field of information and science, can solve the problems of low cost and simple structure of mode-locked lasers, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

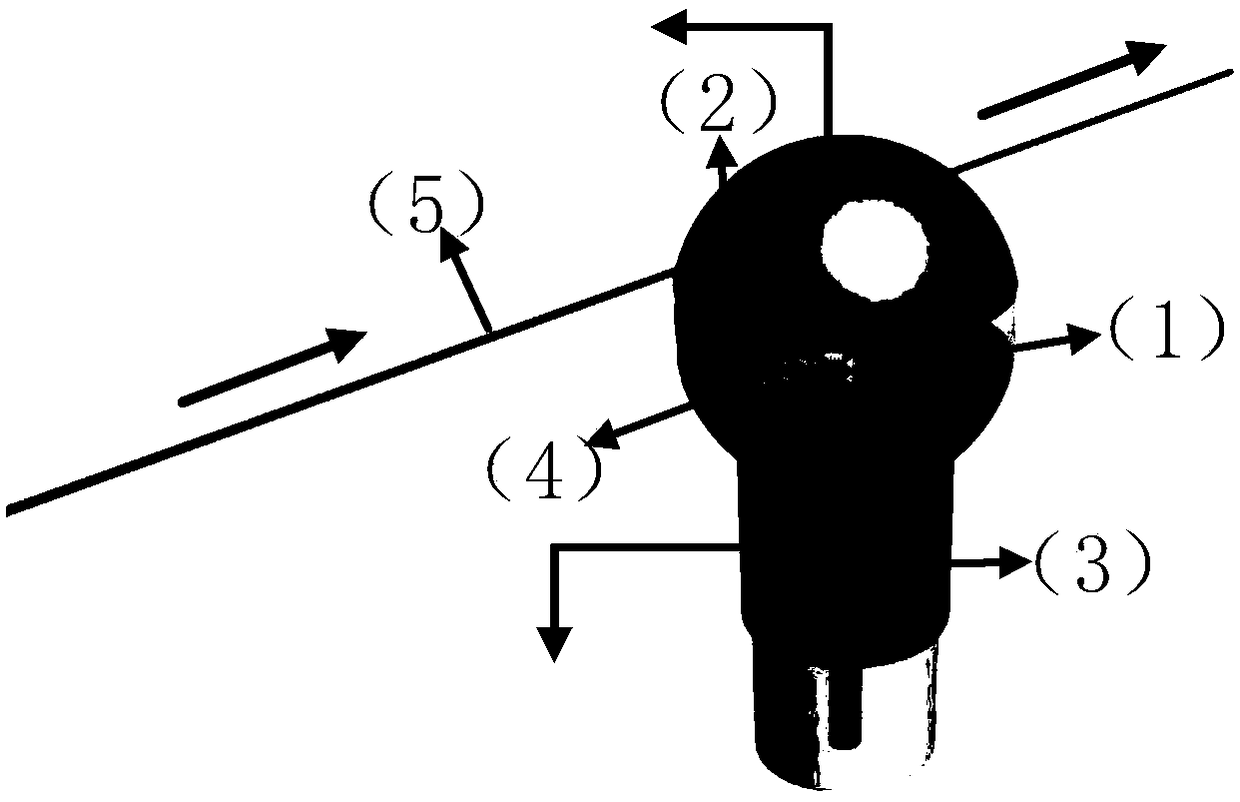

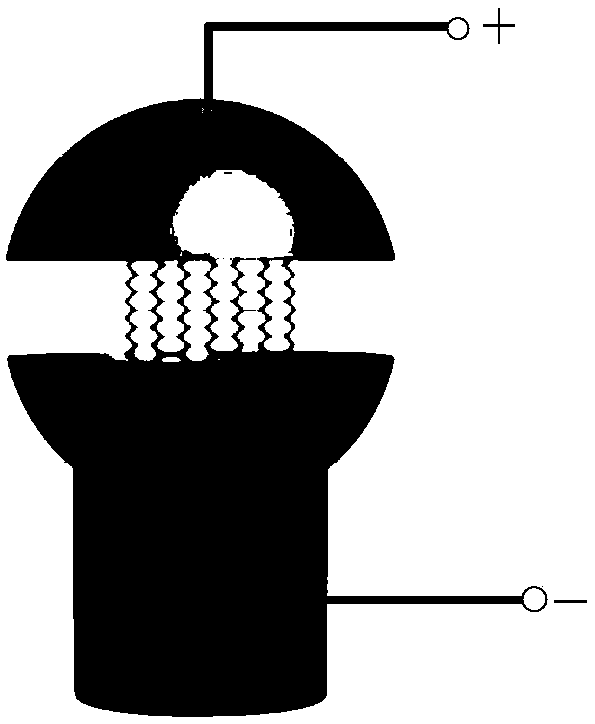

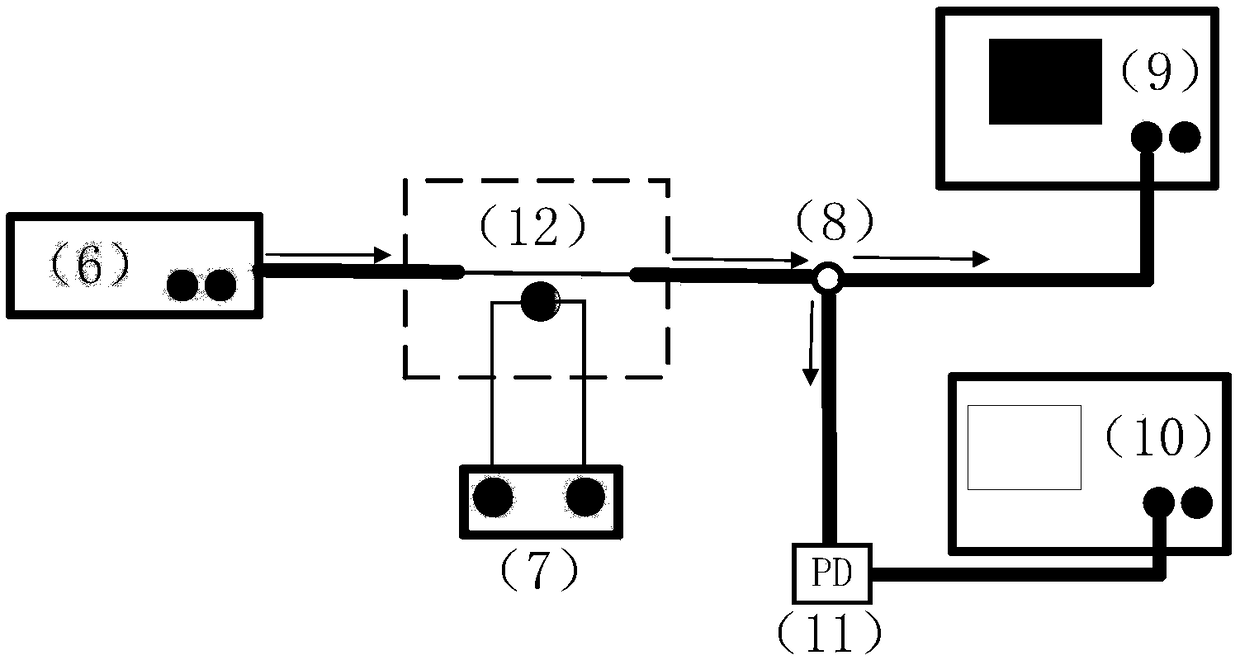

[0023] A fiber microsphere cavity mode-locked laser based on a graphene channel structure is composed of a micro-nano fiber and erbium-doped silica microspheres on the surface. The micro-nano optical fiber is made by optical fiber fusion tapered equipment, with a length of 3 cm and a diameter of 1 micron, which realizes efficient coupling with the microsphere cavity; ordinary single-mode optical fiber passes through the optical fiber fusion splicer with a discharge intensity of 200 mA. The discharge time is 5 seconds and the arc discharge is performed 4 times, and then the mixed solution of erbium chloride-silicon dioxide with a concentration of 1019 / cm3 is configured, and UV glue is added so that the bait ions can be coated on the surface of the microspheres, and finally passed through the hydrogen-oxygen flame The degreasing process removes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com