A kind of nanometer bismuth oxide anti-radiation ceramic coating, preparation method and application

A technology of nano-bismuth oxide and ceramic coating, which is applied in the field of anti-radiation materials, can solve problems such as difficult coating, and achieve the effects of prolonging service life, improving radiation protection performance, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

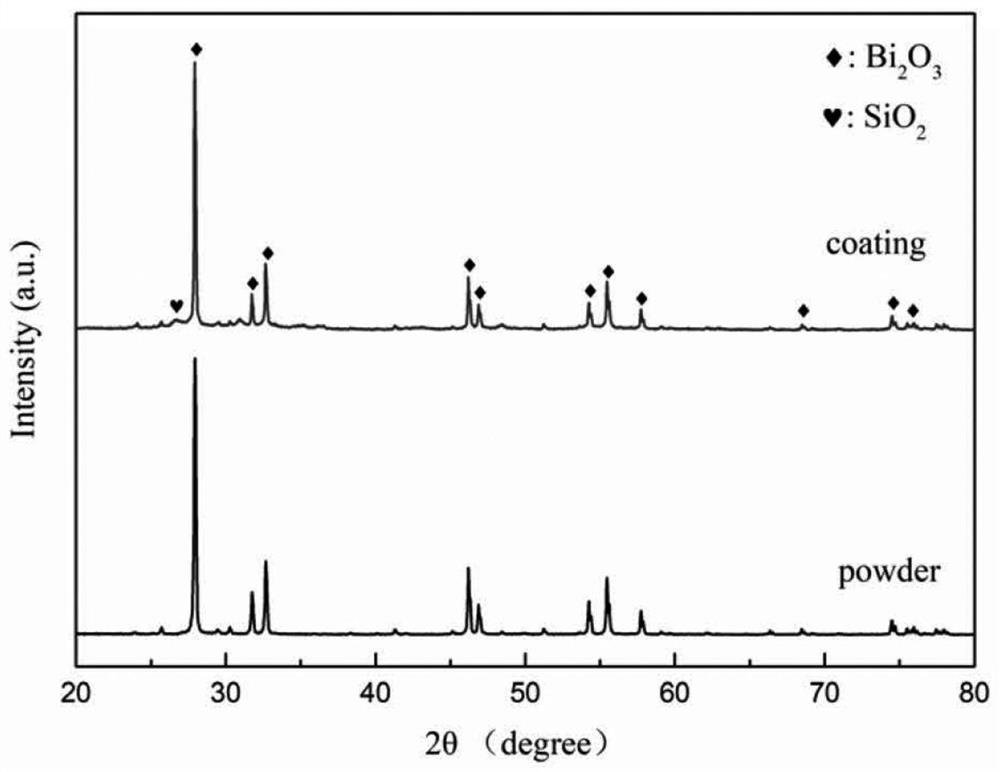

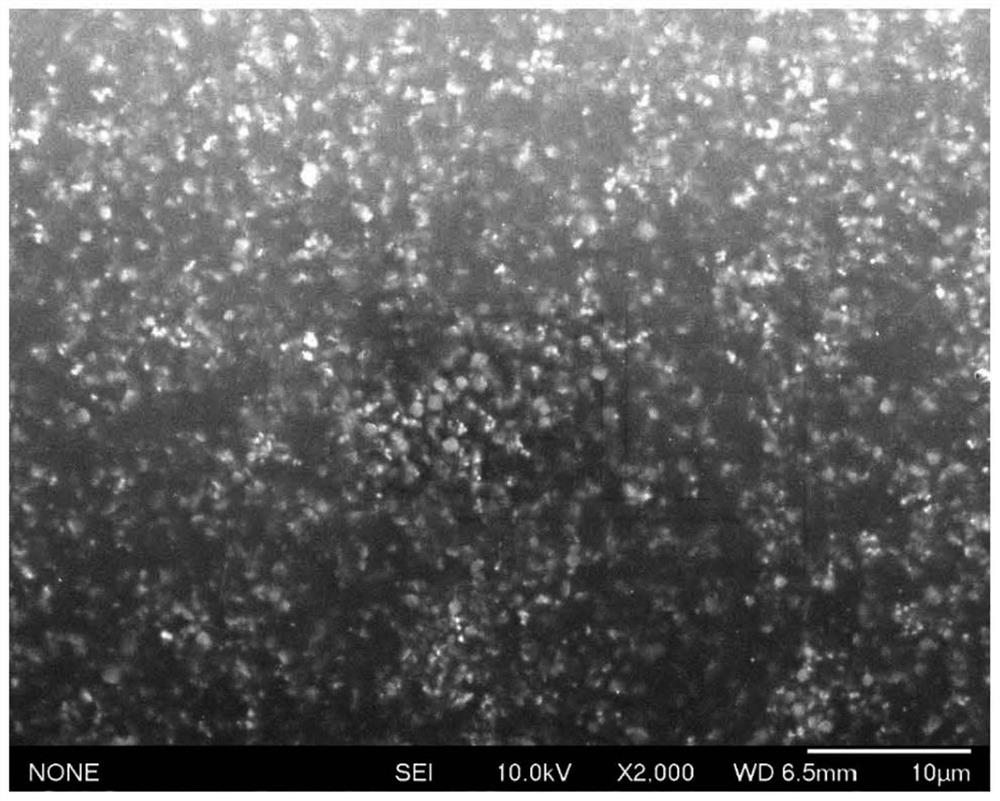

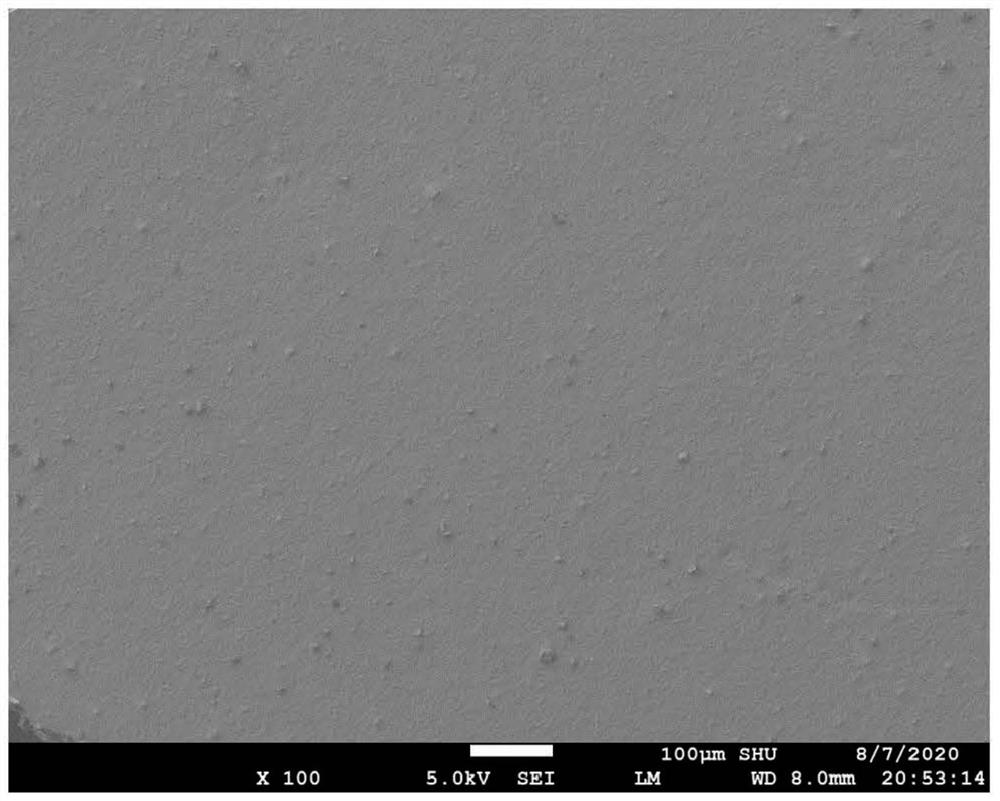

[0040] see Figure 1-Figure 4 , the nano-bismuth oxide anti-radiation ceramic coating provided by the embodiment of the present invention, the ceramic coating is the slurry of the characteristic coating prepared by the following components by mass percentage, and then cured:

[0041]

[0042]

[0043] The slurry of the characteristic coating forms a ceramic coating after curing on the surface of the shell substrate of electronic components (especially microelectronic integrated devices, optoelectronic integrated devices), and the content of bismuth oxide in the ceramic coating can be up to 80wt%.

[0044] The nanometer bismuth oxide of the characteristic coating is nanocrystalline particles with a particle size of ≤500 nm.

[0045] The silane is one or more of ethyl orthosilicate, methyl trimethoxy silane, propyl trimethoxy silane, ethyl trimethoxy silane and epoxy silane.

[0046] The acid is one or more of formic acid, acetic acid and citric acid.

[0047] The solven...

specific Embodiment 1

[0059] The nano-bismuth oxide anti-radiation ceramic coating, preparation method and application provided by the embodiments of the present invention are based on the foregoing embodiments, and the following specific selections are made:

[0060] Its ceramic coating is a slurry of characteristic coatings prepared from the following components by mass percentage, and then cured:

[0061]

[0062]

[0063] The content of bismuth oxide in the ceramic coating is greater than or equal to 80wt%.

[0064] A method for preparing the nanometer bismuth oxide anti-radiation ceramic coating, which comprises the steps:

[0065] S1: Coating Preparation

[0066] According to the ratio set above, the components for preparing the characteristic paint are ball-milled at room temperature for 4 hours at a speed of 250 rmp, mixed uniformly to obtain a slurry, and then the slurry is aged at 60 ° C for 0.5 h to obtain the characteristic paint;

[0067] S2: Coating Preparation

[0068] S2.1 ...

specific Embodiment 2

[0070] The nanometer bismuth oxide anti-radiation ceramic coating, preparation method and application provided in the embodiment of the present invention are basically the same as those in embodiment 1, and the differences are:

[0071] Its ceramic coating is a slurry of characteristic coatings prepared from the following components by mass percentage, and then cured:

[0072]

[0073]

[0074] A method for preparing the nanometer bismuth oxide anti-radiation ceramic coating, which comprises the steps:

[0075] S1: Coating Preparation

[0076] According to the proportions set above, the components of the prepared characteristic paint are ball-milled at room temperature for 4 hours at a speed of 250 rmp, mixed uniformly to obtain a slurry, and then the slurry is aged at 80 °C for 1 hour to obtain the characteristic paint;

[0077] S2: Coating Preparation

[0078] S2.1 After degreasing and dehydrating the surface of the base material of the electronic component casing, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com