Method for measuring electroacoustic conversion efficiency of medical ultrasonic transducer

An ultrasonic transducer, electro-acoustic conversion technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problem of not having a wide range of applications, and achieve the effect of wide application range, simple design and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for measuring the electroacoustic conversion efficiency of a medical ultrasonic transducer, the process is as follows:

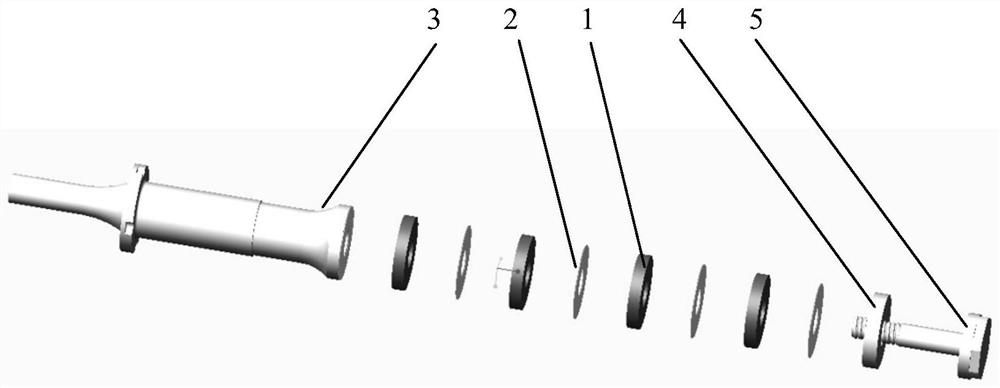

[0054] A. Assembly of ultrasonic transducer: use epoxy resin to polarize PZT4 piezoelectric ceramic sheet with roughness Ra of 400nm (1), silver-plated pure copper electrode sheet (2), front cover aluminum alloy 7075 (3 ) and the rear cover plate 304L stainless steel (4), and then use bolts (5) to fix the above components together, such as figure 2 As shown, the coaxiality is controlled at 0.02mm, and finally the ultrasonic transducer to be tested is obtained by aging at 90°C for 24 hours;

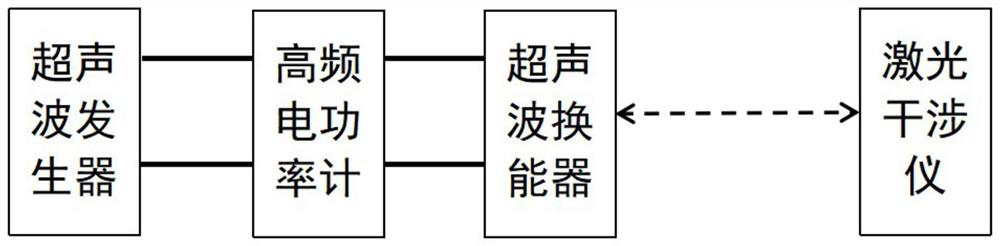

[0055] B. The output end of the ultrasonic generator is connected to the electric power meter, the output end of the electric power meter is connected to the ultrasonic transducer, the ultrasonic generator provides a sinusoidal signal with a frequency of 55KHz, and the input electric power P of the ultrasonic transducer is measured by the electric power ...

Embodiment 2

[0059] A method for measuring the electroacoustic conversion efficiency of a medical ultrasonic transducer, the process is as follows:

[0060] A. Assembly of the ultrasonic transducer: use epoxy resin to glue the polarized PZT8 piezoelectric ceramic sheet with a roughness Ra of 450nm, the silver-plated bronze electrode sheet, the front cover aluminum alloy 7075 and the rear cover 304L stainless steel. , and then use bolts to fix the above components together, the coaxiality is controlled at 0.015mm, and finally carry out aging treatment at 110°C for 12h to obtain the ultrasonic transducer to be tested;

[0061] B. The output end of the ultrasonic generator is connected to the electric power meter, the output end of the electric power meter is connected to the ultrasonic transducer, the ultrasonic generator provides a sinusoidal signal with a frequency of 50KHz, and the input electric power P of the ultrasonic transducer is measured by the electric power meter e 48w;

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com