Coating composition and application thereof

A coating and raw material technology, applied in the coating combination and its application field, can solve the problems of non-environmental protection, difficult to meet the glossiness of vacuum coating, and large skin irritation, and achieve the effect of low price and improved experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] This embodiment provides a paint combination, which includes a primer 1 and a top coat 1, and the specific formulations are shown in Tables 1-2.

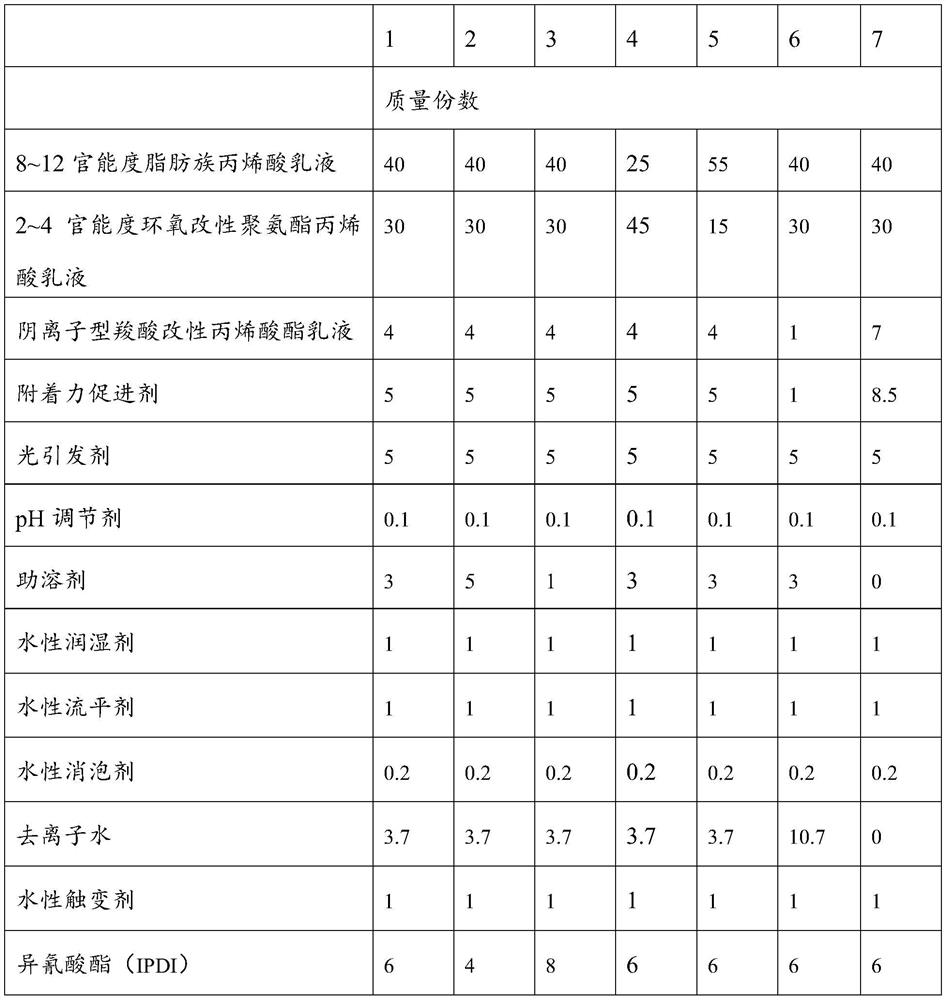

[0131] Table 1 primer ratio

[0132] Primer 1 Primer 2 Primer 3 Primer 4 parts by mass parts by mass parts by mass parts by mass 6-8 functional degree acrylate emulsion 15 5 10 20 2-4 functional acrylate emulsion 55 75 65 45 Water-based alkoxylated UV monomer 15 5 10 20 Photoinitiator 4 4 4 4 pH regulator 0.1 0.1 0.1 0.1 Co-solvent 2 2 2 2 water-based wetting agent 1 1 1 1 Water-based leveling agent 1 1 1 1 Water-based defoamer 0.2 0.2 0.2 0.2 Deionized water 5.7 5.7 5.7 5.7 Water-based thixotropic agent 1 1 1 1

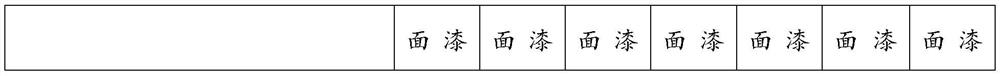

[0133] Table 2 topcoat ratio

[0134]

[0135]

Embodiment 2

[0137] In this embodiment, a paint combination is prepared, which includes a primer 1 and a topcoat 2, wherein the ratio of the primer 1 is shown in Table 1, and the ratio of the topcoat 2 is shown in Table 2.

Embodiment 3

[0139] In this embodiment, a paint combination is prepared, which includes a primer 1 and a topcoat 3, wherein the ratio of the primer 1 is shown in Table 1, and the ratio of the topcoat 3 is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com