Operation tunnel fabricated prefabricated tunnel bottom structure and construction method

A prefabricated, tunnel-bottom technology, applied in tunnels, tunnel linings, mining installations, etc., can solve the problems of high pressure on operating highway traffic, affecting the recovery of tunnels, and long time for concrete strength formation. The effect of shortening the construction period and facilitating on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Composition of structure

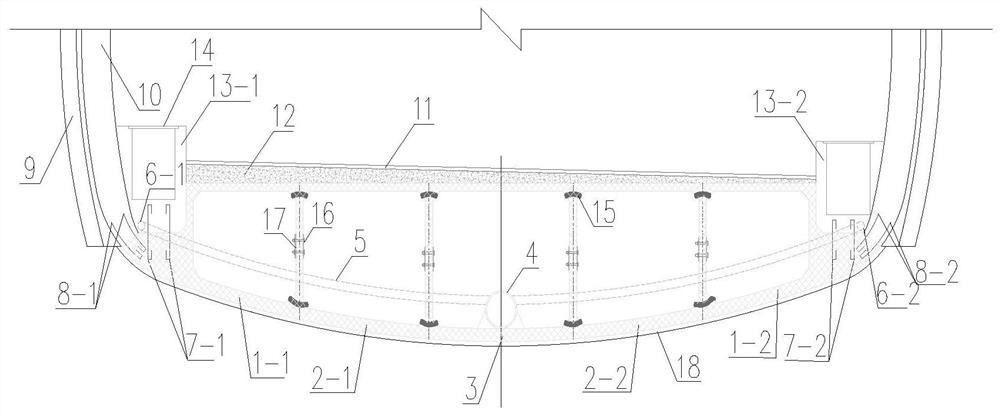

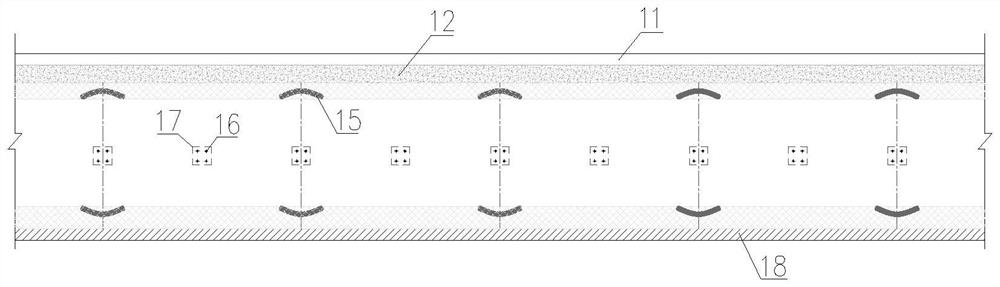

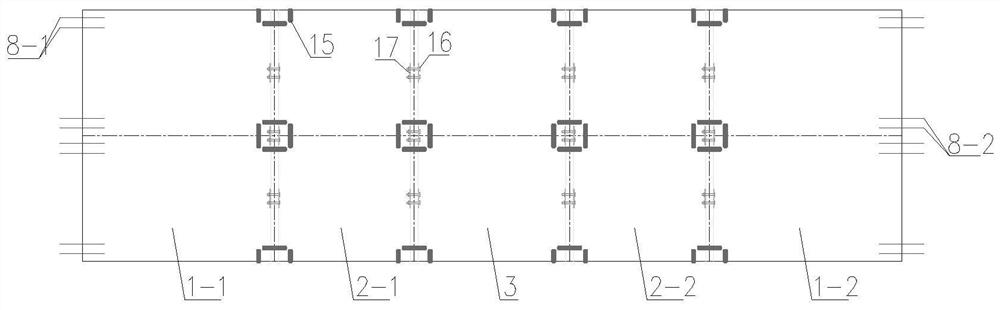

[0065] Such as figure 1 , the UHPC prefabricated prefabricated tunnel bottom structure for the treatment of the bottom of the highway tunnel is composed of the prefabricated UHPC prefabricated tunnel bottom structure, the tunnel bottom drainage system, the cable trough and the pavement layer arranged in the construction and operation tunnel; figure 1 , figure 2 , image 3 , the prefabricated UHPC prefabricated tunnel bottom structure is spliced by multiple prefabricated prefabricated parts. The multi-assembled prefabricated parts have the same structure and size and are arranged from back to front along the longitudinal extension direction of the constructed and operated tunnel; Figure 18 , Figure 19 , Figure 20 The tunnel bottom drainage system includes the left HDPE longitudinal double-wall perforated corrugated pipe 6-1, the right HDPE longitudinal double-wall perforated corrugated pipe 6-2, the HDPE transverse double-wall cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com