Micro-etching processing technology for resin plug hole of dry film cover

A resin plug hole, processing technology, applied in printed circuits, electrical components, and chemical/electrolytic methods to remove conductive materials, etc., can solve problems such as uneven orifices, missing copper in the orifices, and small board line widths. To achieve the effect of good quality, good effect and smooth orifice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A processing technology for micro-etching of resin plug holes in a dry film cover, comprising the following steps:

[0037] S1. Get the engineering data, open the window directly on the resin plug hole 3 of the outer layer cover, the size of the window is 6.5mil larger than the hole diameter on one side, and the alignment system uses a 2.0mm through hole as the alignment reference point;

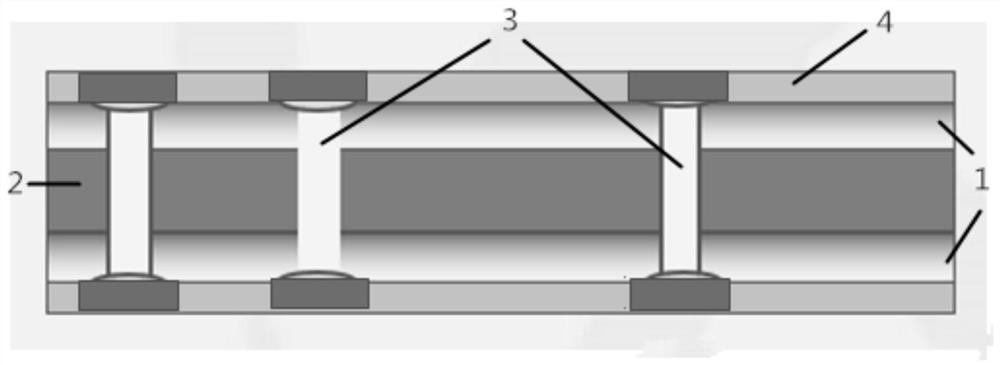

[0038] S2. The outer layer adopts the newly designed negative film engineering data, and dry film 4 is pasted on both sides of the board surface, such as figure 1 As shown, and double-sided exposure, the exposure data is negative polarity;

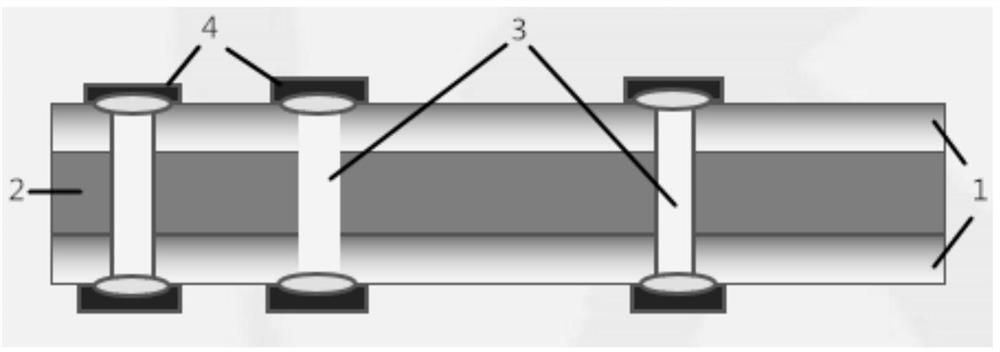

[0039] S3. After standing still for ≥15min, develop. After development, the outer layer is scanned by AOI, and it is confirmed that the dry film 4 completely covers the position of the resin plug hole 3, such as figure 2 shown;

[0040] S4. According to the engineering MI instructions, reduce copper on the plate on the micro-etching line, and u...

Embodiment 2

[0050] A processing technology for micro-etching of resin plug holes in a dry film cover, comprising the following steps:

[0051] S1. Get the engineering data, open the window directly on the resin plug hole 3 of the outer layer cover, the size of the window is 6.5mil larger than the hole diameter on one side, and the alignment system uses a 2.0mm through hole as the alignment reference point;

[0052] S2. The outer layer adopts the newly designed negative film engineering data, and dry film 4 is pasted on both sides of the board surface, such as figure 1 As shown, and double-sided exposure, the exposure data is negative polarity;

[0053] S3. After standing still for ≥15min, develop. After development, the outer layer is scanned by AOI, and it is confirmed that the dry film 4 completely covers the position of the resin plug hole 3, such as figure 2 shown;

[0054] S4. According to the engineering MI instructions, reduce copper on the plate on the micro-etching line, and use...

Embodiment 3

[0064] A processing technology for micro-etching of resin plug holes in a dry film cover, comprising the following steps:

[0065] S1. Get the engineering data, open the window directly on the resin plug hole 3 of the outer layer cover, the size of the window is 6.5mil larger than the hole diameter on one side, and the alignment system uses a 2.0mm through hole as the alignment reference point;

[0066] S2. The outer layer adopts the newly designed negative film engineering data, and dry film 4 is pasted on both sides of the board surface, such as figure 1 As shown, and double-sided exposure, the exposure data is negative polarity;

[0067] S3. After standing still for ≥15min, develop. After development, the outer layer is scanned by AOI, and it is confirmed that the dry film 4 completely covers the position of the resin plug hole 3, such as figure 2 shown;

[0068] S4. According to the engineering MI instructions, reduce copper on the plate on the micro-etching line, and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com