Preparation method of formaldehyde-removing color-changing gel

A gel and formaldehyde technology, applied in the field of preparation of formaldehyde-removing discoloration gel, can solve the problems of poor formaldehyde-removing effect of activated carbon, inability to visually display the formaldehyde-removing effect, gastrointestinal dysfunction, etc., so as to avoid gel deterioration and inhibit microorganisms. effect of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a technical solution: a preparation method of formaldehyde-removing color-changing gel, comprising the following steps:

[0025] S1. Weigh the raw materials according to the weight ratio, and place the raw materials in the designated position for preparation;

[0026] S2. Add the tea polyphenols to deionized water, put it into a stirring kettle at a temperature of 50-70° C., stir and mix evenly, and cool to obtain a mixed solution;

[0027] S3. Put the nano-photocatalyst and hydroxylamine phosphate into a stirring tank, stir for 1-3 hours, and mix evenly to obtain a mixed powder;

[0028] S4. Add mixed powder, preservative, antibacterial agent and peppermint oil to the mixed solution, control the temperature at 30-50° C., stir and mix evenly to obtain a pretreatment solution;

[0029] S5. Put the pretreatment solution and gel powder into a heating tank at a temperature of 100-130° C., stir for 2-4 hours, take it out and cool to room temperature, ...

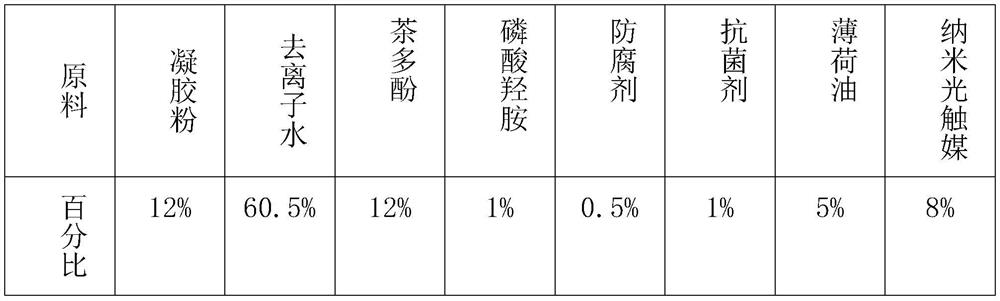

Embodiment 1

[0045] Embodiment 1, by weight ratio is gel powder 12%, deionized water 60.5%, tea polyphenols 12%, hydroxylamine phosphate 1%, preservative 0.5%, antibacterial agent 1%, peppermint oil 5% and nano photocatalyst 8 %.

[0046]

[0047] A preparation method for formaldehyde-removing color-changing gel, comprising the following steps:

[0048] S1. Weigh the raw materials according to the weight ratio, and place the raw materials in the designated position for preparation;

[0049] S2. Add tea polyphenols to deionized water, place in a stirred tank at a temperature of 50°C for 0.5 h, stir at a speed of 60 r / min, stir and mix evenly, and cool to obtain a mixed solution;

[0050] S3. Put the nano photocatalyst and hydroxylamine phosphate into a stirring tank, stir for 1 hour, mix evenly, and obtain a mixed powder;

[0051]S4. Add mixed powder, preservative, antibacterial agent and peppermint oil to the mixed solution, control the temperature at 30°C, stir at a speed of 100r / min...

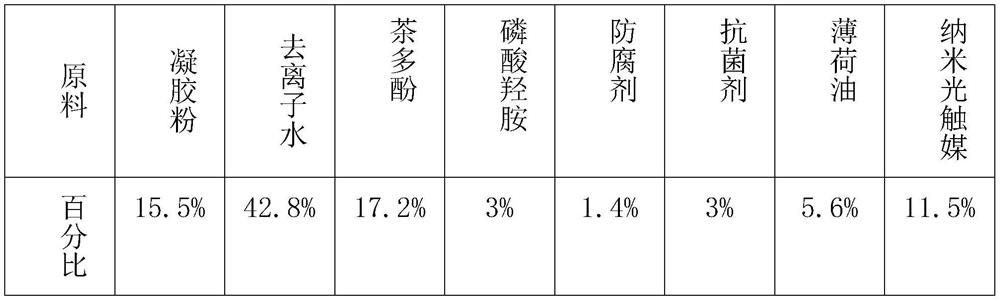

Embodiment 2

[0059] Embodiment 2, by weight ratio is gel powder 15.5%, deionized water 42.8%, tea polyphenols 17.2%, hydroxylamine phosphate 3%, antiseptic 1.4%, antibacterial agent 3%, peppermint oil 5.6% and nano photocatalyst 11.5% %.

[0060]

[0061] A preparation method for formaldehyde-removing color-changing gel, comprising the following steps:

[0062] S1. Weigh the raw materials according to the weight ratio, and place the raw materials in the designated position for preparation;

[0063] S2. Add tea polyphenols to deionized water, place in a stirred tank at a temperature of 70°C for 1.5 hours, stir at a speed of 120r / min, stir and mix evenly, and cool to obtain a mixed solution;

[0064] S3. Put the nano photocatalyst and hydroxylamine phosphate into a stirring tank, stir for 3 hours, mix evenly, and obtain a mixed powder;

[0065] S4. Add mixed powder, preservative, antibacterial agent and peppermint oil to the mixed solution, control the temperature at 50° C., stir at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com