Sn-based brazing filler metal capable of achieving high-strength interconnection of CSP devices

A high-strength, brazing material technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve problems that have not been recorded, achieve high strength and service life, good solder joints, high mechanical properties, and meet Effect of High Reliability Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

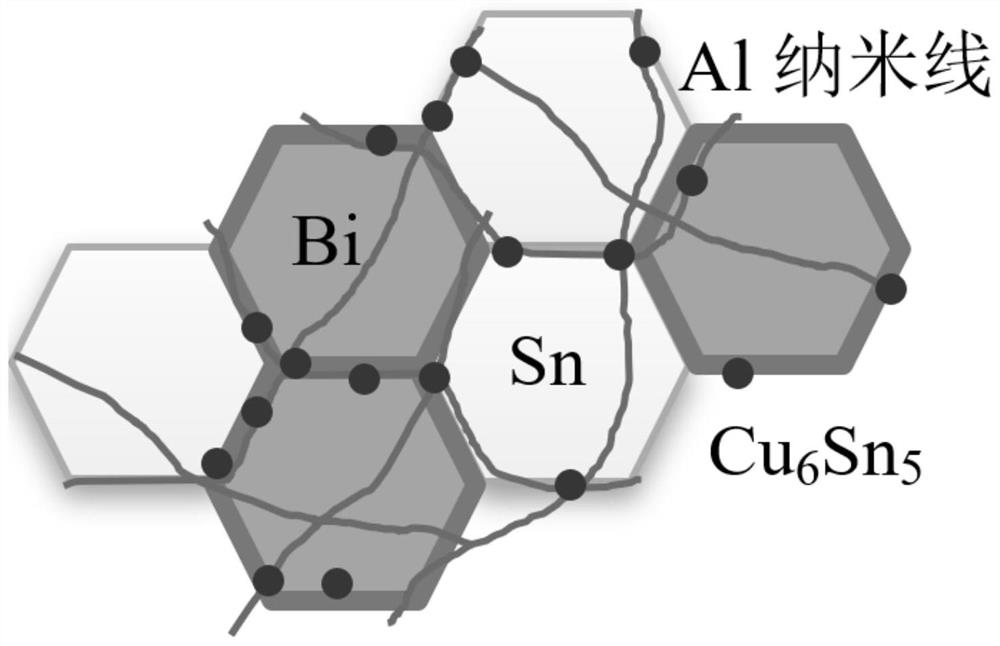

[0020] Composition and mass percent of Sn in the brazing material of the present invention is based is: Al nanowires content 0.2%, Cu content of the submicron particles of 1.0%, Bi content of 57%, the balance being Sn.

[0021]Solder temperature performance test: Under the premise of test error, the solid phase temperature is around 138.2 ° C, and the liquid phase temperature is around 140 ° C.

Embodiment 2

[0023] The composition and mass percentage of the Sn-based solder of the present invention are: Al nano-content is 0.3%, and the Cu submicron particle content is 1.5%, the BI content is 57%, and the remaining amount is Sn.

[0024] Solder temperature performance test: Consider the test error, the solid phase temperature is around 138.3 ° C, the liquid phase temperature is around 140.5 ° C.

Embodiment 3

[0026] The composition and mass percentage of the Sn-based solder of the present invention are: Al nanowire content is 0.4%, and the Cu submicron particle content is 2.0%, the BI content is 56%, and the remaining amount is Sn.

[0027] Solder temperature performance test: Under the premise of test error, the solid phase temperature is around 138.4 ° C, and the liquid phase temperature is around 140.7 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com