A kind of rubber tree log and root wood production root carving and wood pier processing method

A processing method, rubber tree technology, applied in wood processing equipment, wood treatment, wood heat treatment, etc., can solve the problems of low added value, color, texture, density and dimensional stability, decay, etc., to achieve a stable equilibrium moisture content, Elegant color and pattern, stable wood size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

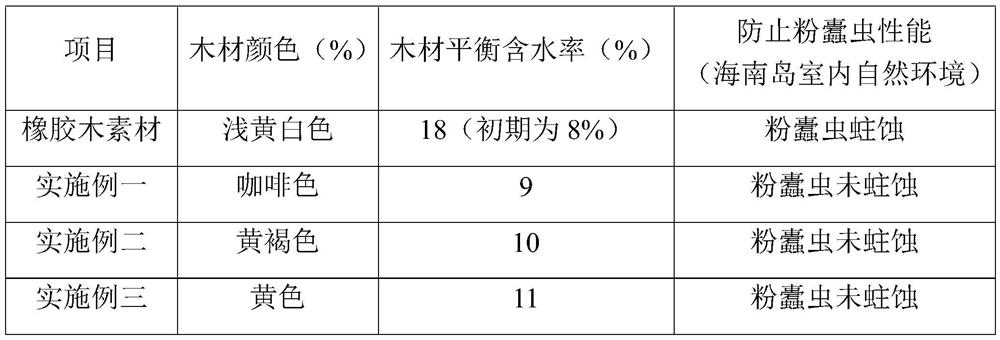

Examples

Embodiment 1

[0029] 1), rubber tree root cleaning, removing mud, root diameter 40-80cm, length 50-100cm, initial moisture content 70-80%, 20 in number;

[0030] 2), place the tree roots on the lumber truck, stack them and fix them properly with steel ropes to keep them stable, and wait for drying and high temperature treatment;

[0031] 3) Put the stacked tree roots into the wood high-temperature drying treatment kiln, heat it, and pass in steam to heat up to 90 °C, continue to heat during the day, shut down the kiln at night, cool down to 50 °C naturally, close the inlet and exhaust ports or Slightly open, repeat the operation for 7 days, raise the temperature of the kiln and pass in steam, raise the temperature to 120°C, continue to heat during the day, shut down the kiln at night, cool down to 85°C naturally, close the inlet and exhaust ports, and the processing time is 48 hours, raise the kiln again Temperature to 155 ℃, treatment time is 24 hours, the inlet and exhaust ports are close...

Embodiment 2

[0034] 1), rubber tree logs are cleaned to remove mud, the log diameter is 50-70cm, the length is 200-230cm, the number is 5, and the initial moisture content is 60-70%;

[0035] 2), put the logs on the lumber car, stack them and separate them with spacers, and wait for drying and high temperature treatment;

[0036] 3) Put the stacked logs into the wood high-temperature drying treatment kiln, heat it, and pass in steam to heat up to 80 °C, continue to heat during the day, shut down the kiln at night, and naturally cool down to 55 °C, close the intake and exhaust ports or slightly. Open, repeat the operation for 7 days, raise the temperature of the kiln and pass in steam, raise the temperature to 115 °C, continue to heat during the day, shut down the kiln at night, and naturally cool down to 80 °C, close the inlet and exhaust ports, and the processing time is 72 hours, and the kiln temperature is raised again. To 150 ° C, the treatment time is 24 hours, the inlet and exhaust p...

Embodiment 3

[0039] 1), clean the rubber wood logs, remove the mud, the log diameter is 10-20cm, the length is 200-300cm, the number is 100 sections, and the initial moisture content is 50-60%;

[0040] 2), put the logs on the lumber truck, stack and separate them with spacers, and wait for drying and high temperature treatment;

[0041] 3) Put the stacked logs into the wood high-temperature drying treatment kiln, heat it, and pass in steam to raise the temperature to 87 °C, continue to heat during the day, shut down the kiln at night, cool down to 57 °C naturally, close the intake and exhaust ports or slightly. Open, repeat the operation for 3 days, raise the temperature of the kiln and pass in steam, raise the temperature to 125 °C, continue to heat during the day, shut down the kiln at night, cool down to 90 °C naturally, close the inlet and exhaust ports, and the treatment time is 24 hours, and increase the kiln temperature again. To 157°C, the treatment time is 12 hours, the inlet and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com