A kind of environment-friendly concentrated liquid for hydraulic support and preparation method thereof

A technology of hydraulic support and concentrated liquid, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of anti-rust performance, limitation of lubricity and resistance to hard water, blockage of filter components in electro-hydraulic control system, price impact, etc., to achieve protection Normal operation, good cold water cleaning performance, low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

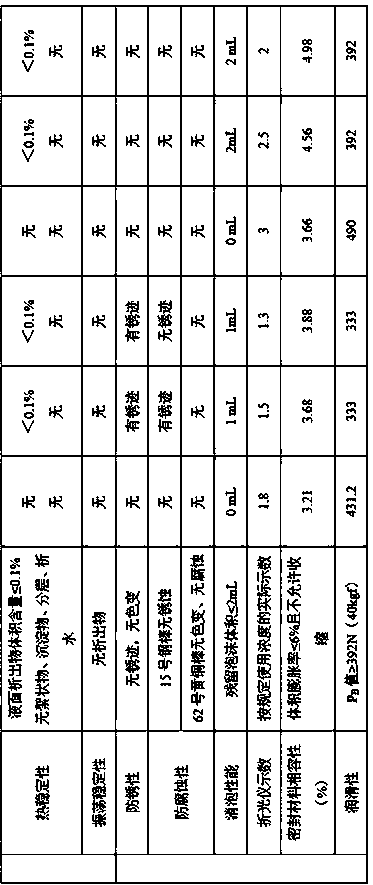

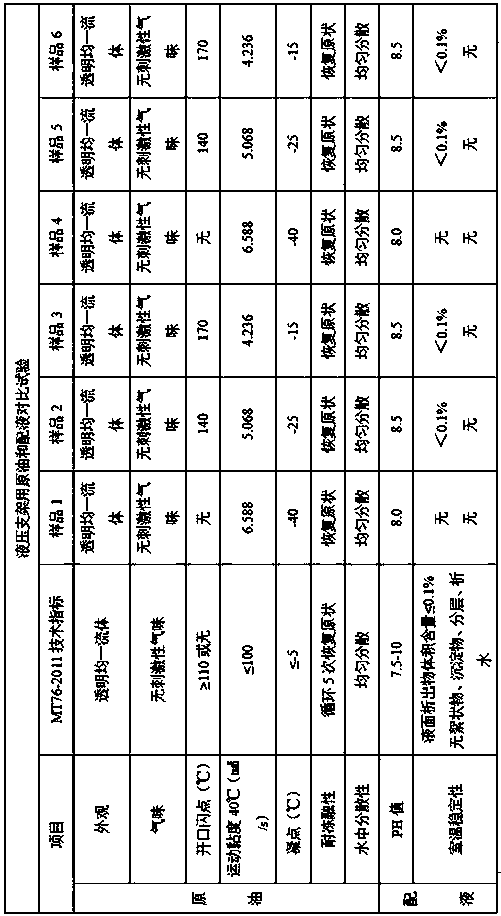

Examples

Embodiment 1

[0024] An environment-friendly concentrated solution for hydraulic supports, the components and mass percentages are:

[0025] Glycerin 30%

[0026] Rust inhibitor 3%

[0027] Lubricating compound 15%

[0028] Emulsifying compound 8%

[0029] Anti-rust and anti-corrosion water 15%

[0030] EDTA-2Na water softener 3%

[0031] water 26%

[0032] The antirust agent is a glycerin saturated solution of borax, which is to dissolve borax in glycerin at 60°C to 70°C, and take the upper layer of transparent and clear liquid;

[0033] The lubricating compound is obtained by compounding triethanolamine, ricinoleic acid sulfate sodium salt and glycerin according to the mass ratio of 2:2:5;

[0034] The emulsifying compounding agent is obtained by compounding sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester, fatty acid polyoxyethylene ester and fatty alcohol polyoxyethylene ether in a mass ratio of 1:1:1:1;

Embodiment 2

[0038] An environment-friendly concentrated solution for hydraulic supports, the components and mass percentages are:

[0039] Glycerin 25%

[0040] Rust inhibitor 3%

[0041] Lubricating compound 17%

[0042] Emulsifying compound 8%

[0043] Anti-rust and anti-corrosion water 15%

[0044] EDTA-2Na water softener 3%

[0045] water 29%

[0046] The antirust agent is a glycerin saturated solution of borax, which is to dissolve borax in glycerin at 60°C to 70°C, and take the upper layer of transparent and clear liquid;

[0047] The lubricating compound is obtained by compounding triethanolamine, ricinoleic acid sulfate sodium salt and glycerin according to the mass ratio of 1:1:3;

[0048] The emulsifying compounding agent is obtained by compounding sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester, fatty acid polyoxyethylene ester and fatty alcohol polyoxyethylene ether according to the mass ratio of 2:2:2:3;

[0049] The anti-rust and anti-corrosion wa...

Embodiment 3

[0052] An environment-friendly concentrated solution for hydraulic supports, the components and mass percentages are:

[0053] Glycerin 40%

[0054] Rust inhibitor 4%

[0055] Lubricating compound 16%

[0056] Emulsifying compound 8%

[0057] Anti-rust and anti-corrosion water 12%

[0058] EDTA-2Na water softener 4%

[0059] Water 16%

[0060] The antirust agent is a glycerin saturated solution of borax, which is to dissolve borax in glycerin at 60°C to 70°C, and take the upper layer of transparent and clear liquid;

[0061] The lubricating compound is obtained by compounding triethanolamine, ricinoleic acid sulfate sodium salt and glycerin according to the mass ratio of 1:1:3;

[0062]The emulsifying compounding agent is obtained by compounding sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester, fatty acid polyoxyethylene ester and fatty alcohol polyoxyethylene ether in a mass ratio of 1:1:1:1;

[0063] The anti-rust and anti-corrosion water is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com