Catalytic cracking method for producing high aromatic hydrocarbon oil and productive liquefied gas

A catalytic cracking, high aromatics technology, applied in the treatment of hydrocarbon oil, multi-stage series-connected refining and cracking process treatment, petroleum industry, etc. It can solve the problems of high equipment investment and operating costs, improve product distribution, and increase reaction temperature. , the effect of meeting the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

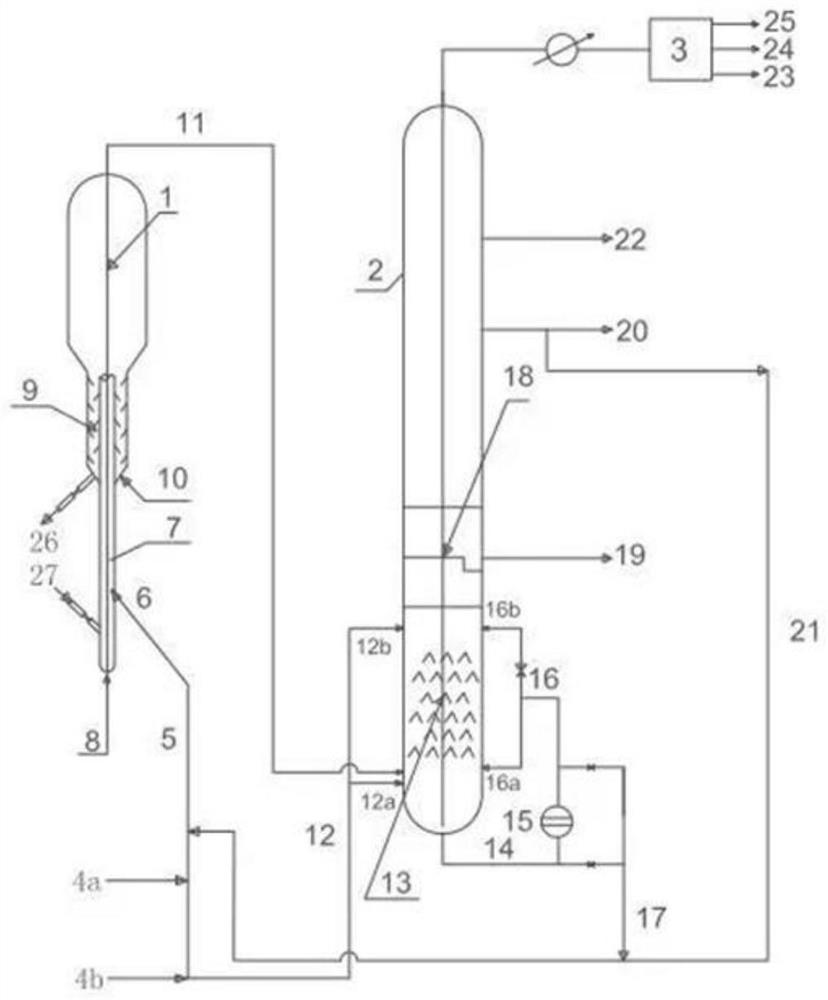

[0091] Such as figure 1 As shown, the FCC feedstock oil and the catalytic cracking catalyst undergo a catalytic cracking reaction in the riser reactor 7 to form reaction oil gas. The operating conditions of the catalytic cracking reaction are shown in Table 2 below.

[0092] Such as figure 1 As shown, the reaction oil gas from the reaction unit is fed to below the washing and desuperheating section of the catalytic cracking fractionation tower 2, and the reaction oil gas is fully contacted with the FCC feedstock oil in the washing and desuperheating section 13 to elute the reaction oil gas containing catalyst powder. The operating conditions of the fractionation tower are shown in Table 2 below.

[0093] In the fractionation tower, high-aromatic oil, heavy diesel oil (as required) and light diesel oil are extracted sequentially from bottom to top, and gasoline, liquefied gas and dry gas are obtained through subsequent absorption and stabilization unit separation. The pro...

Embodiment 2-3

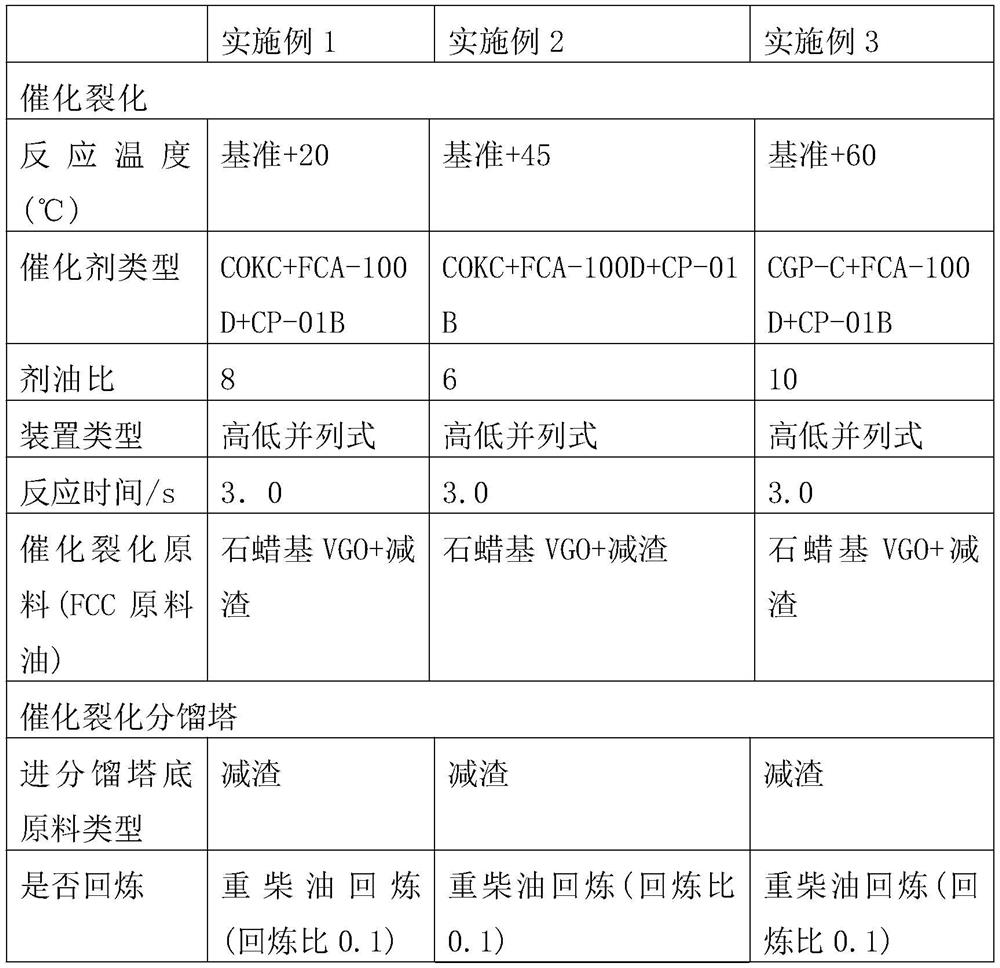

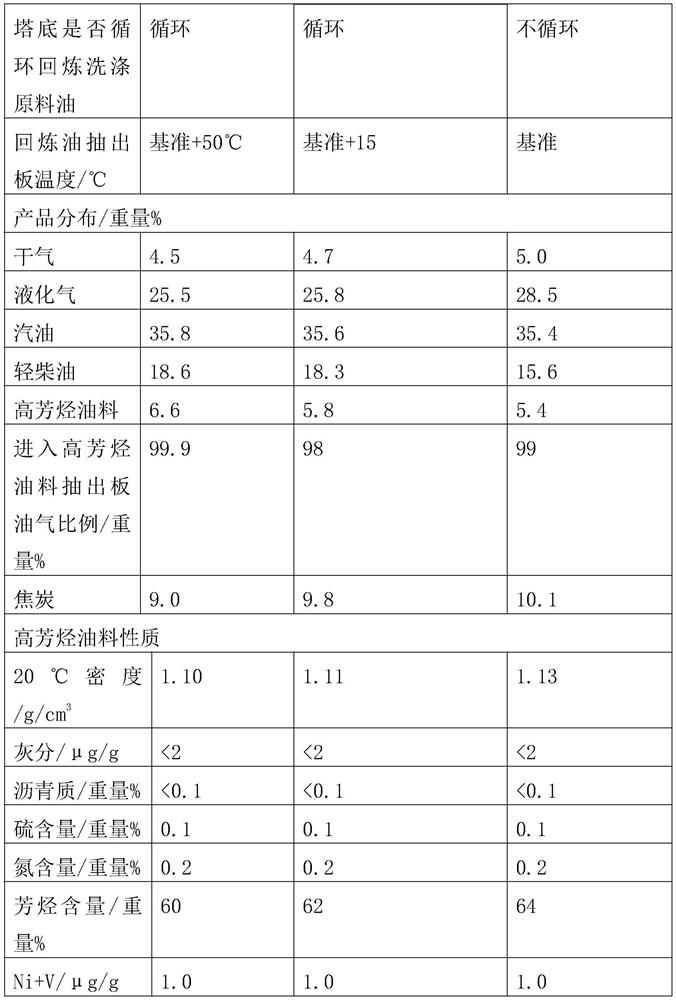

[0095] According to the conditions described in Table 2, the steps similar to those described in Example 1 were used to prepare high aromatics oil. The product distribution of Examples 2-3 can be seen in Table 2 below. Moreover, the properties of the high aromatics oil produced in Example 2-3 are shown in Table 2 below. Its liquefied gas composition is shown in Table 2a.

[0096] Table 2

[0097]

[0098]

[0099] Table 2a

[0100]

Embodiment 4-6

[0102] According to the conditions described in Table 3, the steps similar to those described in Example 1 were used to prepare high aromatics oil. The product distribution of Examples 4-6 can be seen in Table 3 below. Moreover, the properties of the high aromatics oil produced in Examples 4-6 are shown in Table 3 below. Its liquefied gas composition is shown in Table 3a.

[0103] table 3

[0104]

[0105]

[0106]

[0107] Table 3a

[0108]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com