Semi-continuous reaction distillation process for producing carbonic ester

A reactive distillation and semi-continuous technology, applied in the carbonate field, can solve the problems of difficulty for new entrants to enter the linear carbonate market, increase in impurity generation and equipment costs, and high threshold for capital investment, so as to reduce equipment investment and operating costs, reduce Equipment investment cost, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

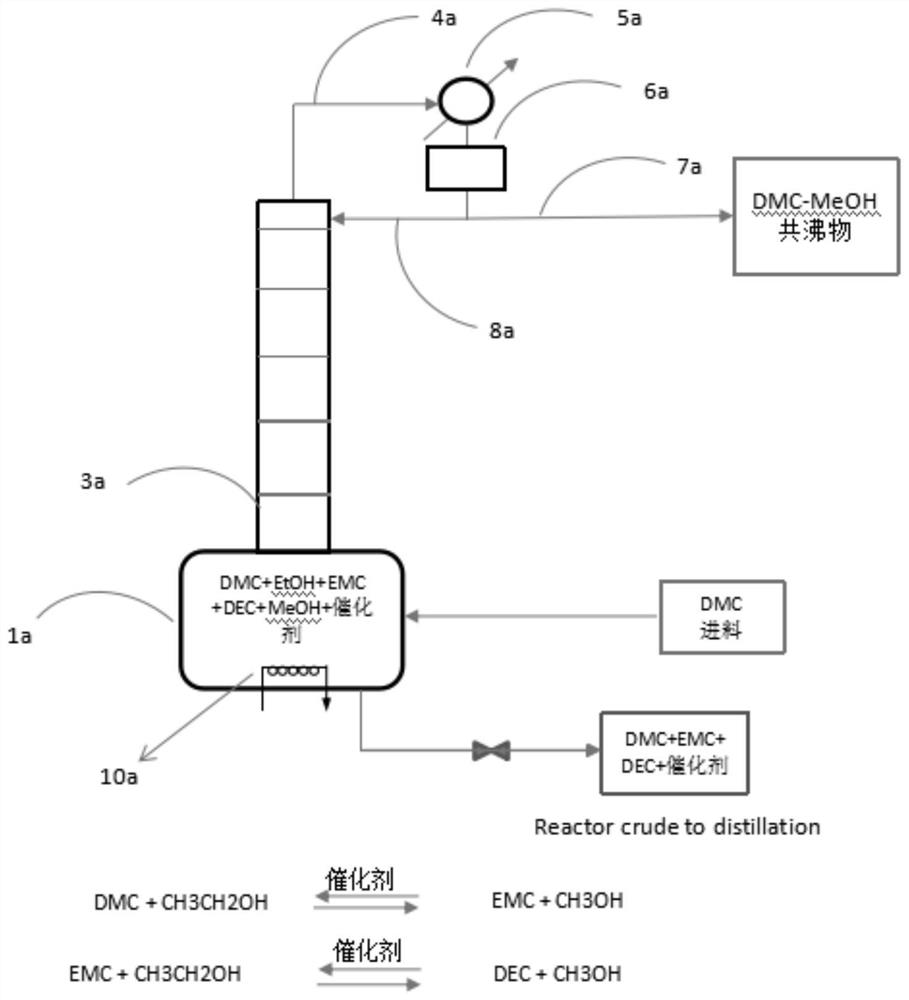

[0047] Example 1: Production of high-purity EMC and DEC from DMC

[0048] Such as figure 1 As shown, a conventional batch distillation system is characterized in that the still pot is equipped with a stirrer and used as a reactor. The reactor was filled with DMC and ethanol in a molar ratio of 1:1. Sodium methoxide (dissolved in methanol) was used as catalyst. The operation steps are as follows:

[0049] (1) The reactor is heated to a reaction temperature of 65-85°C. The distillation column was operated at total reflux until the temperature at the top of the column reached 63.5° C. (DMC-methanol azeotrope temperature at atmospheric pressure). Then continue to carry out reactive distillation at a reflux ratio of 3:1, and adjust the reactor temperature so that the temperature at the top of the tower is controlled at about 63.5°C.

[0050] (2) When the reaction temperature begins to rise and the flow at the top of the tower begins to decrease, start to pump fresh DMC raw mat...

example 2

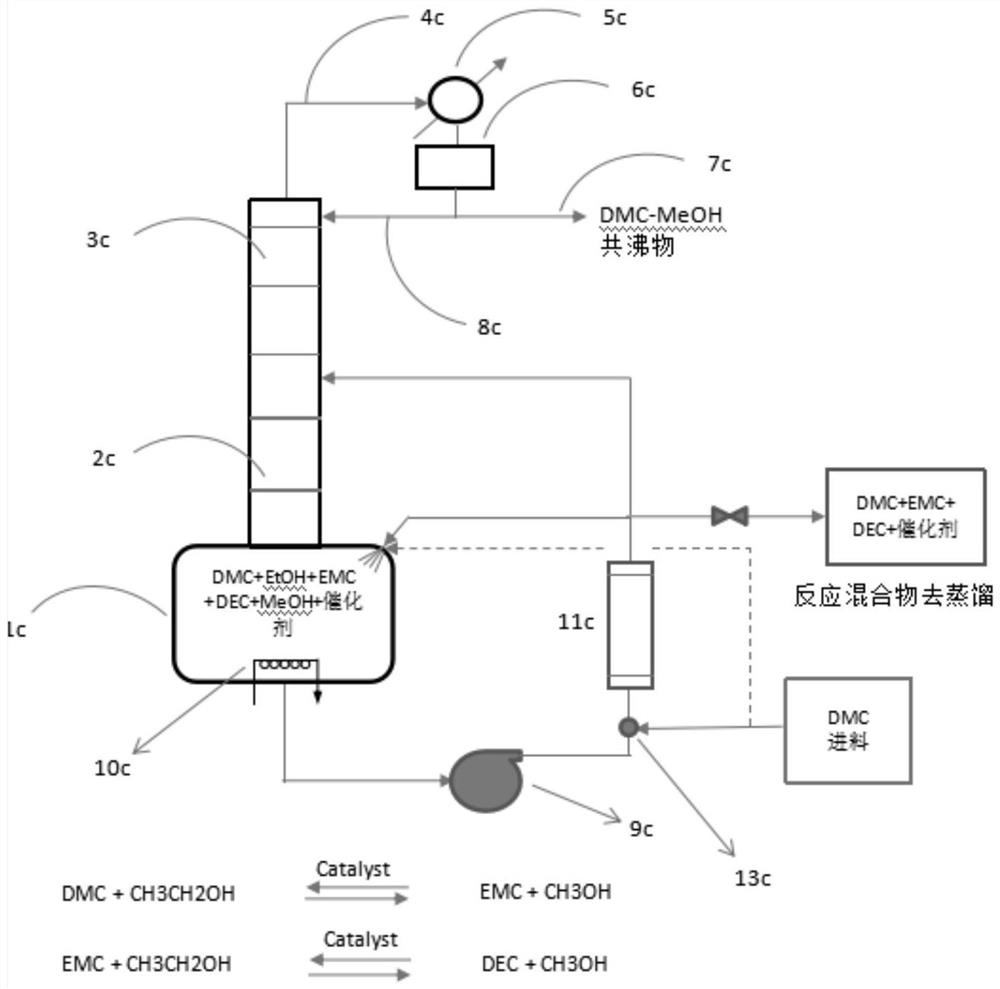

[0062] Example 2, such as image 3 As shown, the conventional batch distillation unit used in Example 1 was changed into a semi-continuous distillation unit. A recirculation pump is added to pump the reaction mixture into the column or into the reactor vapor space to enhance the heat and mass transfer of the reactive distillation. Heat exchange can be added to the circulation loop to increase heating / cooling capacity, but this heat exchanger is optional depending on other design parameters of the plant and the characteristics of the reaction.

[0063] The recycle loop entry point can be any point in the distillation column. By introducing the reaction mixture into the column, which thus has a stripping and rectifying section, the column batch column can be used as a continuous distillation column 13, thereby increasing the efficiency of the column. In a typical batch distillation operation, the column has only a rectifying section and no stripping section. This recirculatio...

example 3

[0077] Example 3, Preparation of Dimethyl Carbonate (DMC) from Ethylene Carbonate (EC)

[0078] Such as Figure 6 As shown, a set of reactive distillation column is used to make industrial-grade EC react with industrial-grade methanol to produce DMC. The catalyst used is still sodium methoxide. The reactive distillation system adds a recirculation loop that enters the top of the reaction section of the tower, as Figure 6 shown. The operating steps of this system are similar to Example 2.

[0079] (1) Add EC and methanol at a molar ratio of 1:2 to the reactor. The catalyst sodium methoxide was added to speed up the reaction. Heating to 65-80 ° C, so that the distillation column is in a state of complete reflux. When the temperature at the top of the tower reaches 63.5°C, change to operate at a reflux ratio of 3:1, and take out the top product (ie DMC / MeOH azeotrope).

[0080] (2) When the overhead flow drops and the temperature begins to drop, start introducing fresh me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com