Preparation method of indirect coal liquefaction residue asphalt mixture

A technology of asphalt mixture and liquefaction residue, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of restricting the development of road construction, component loss and waste, sand and gravel shortage, etc., and achieve obvious economic Benefits and social benefits, high value-added utilization, high temperature performance and excellent water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

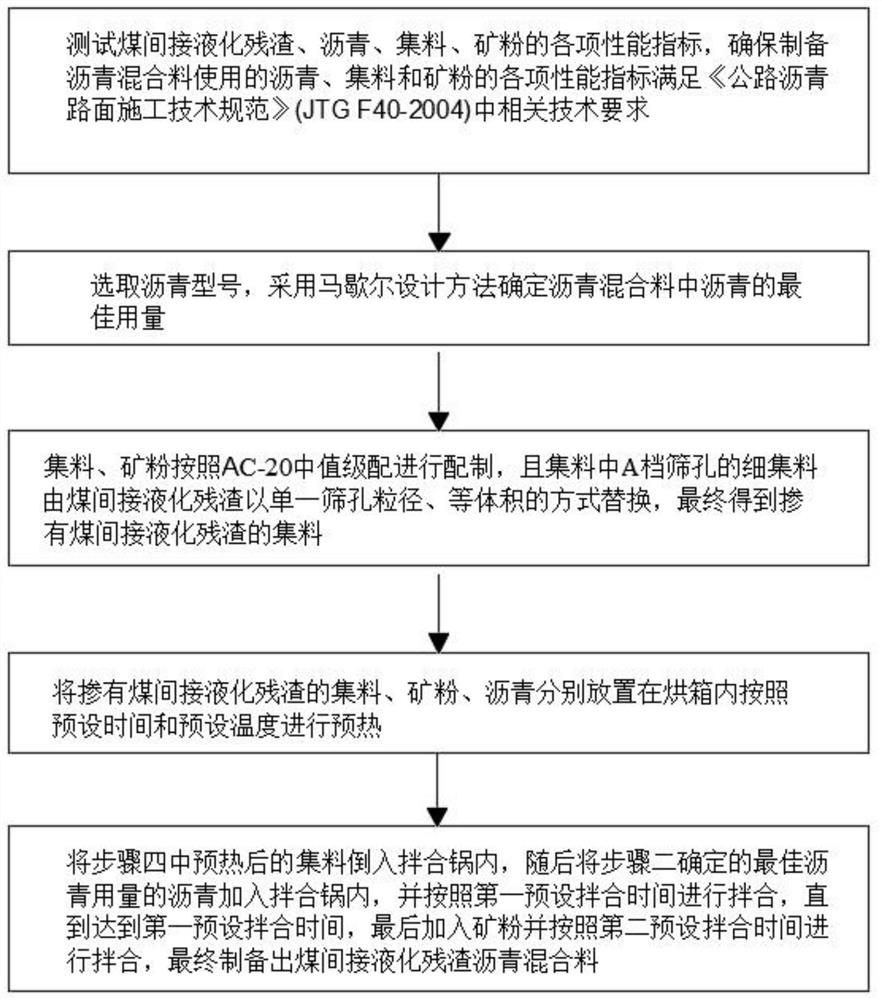

[0027] like figure 1 As shown, according to an embodiment of the preparation method of a kind of coal indirect liquefaction residue asphalt mixture provided by the present invention, the following steps are included in sequence,

[0028] Step 1: Test the various performance indicators of coal indirect liquefaction residue, asphalt, aggregate, and mineral powder to ensure that the various performance indicators of the asphalt, aggregate, and mineral powder used in the preparation of asphalt mixture meet the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004) related technical requirements;

[0029] Step 2, select the type of asphalt, and use the Marshall design method to determine the optimal amount of asphalt in the asphalt mixture;

[0030] Step 3, the aggregate and mine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com