Quantum dot reflective material and preparation method and application thereof

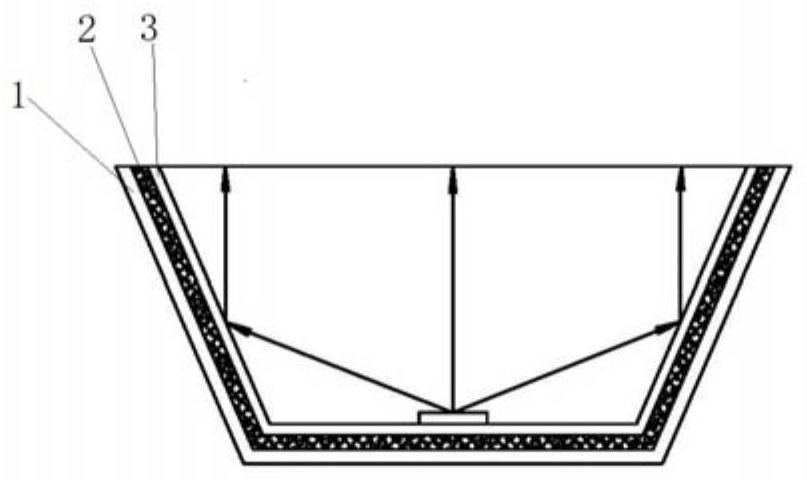

A technology of reflective materials and quantum dots, applied in the direction of light source, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., to achieve the effect of high light efficiency, low color temperature deviation, and avoiding light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Preparation of quantum dot dispersion

[0069] Quantitative red light quantum dots and dispersant were weighed and dissolved in cyclohexane solution, ultrasonicated and vibrated until the quantum dots were dissolved. Then stir the dispersion until uniformly dispersed for use.

[0070] 2. Preparation of quantum dot reflective adhesive

[0071] Add the quantum dot dispersion liquid quantitatively to the epoxy resin stirred at high speed at a uniform speed, and continue to stir until fully dispersed.

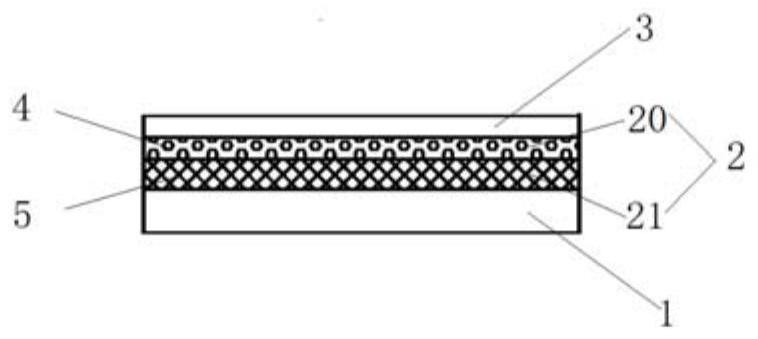

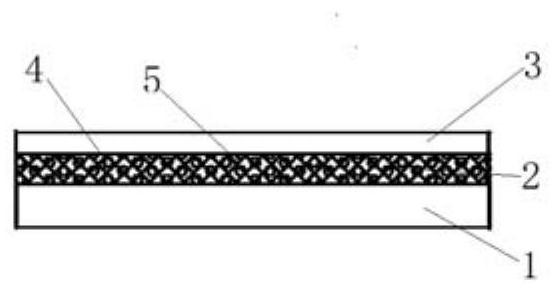

[0072] 3. Molding

[0073] After devolatilizing the residual organic solvent, impregnate the quantum dot reflective glue on the surface of the high polymer resin to form the quantum dot reflective layer 2; finally, cure the protective layer 3 on the surface of the cured quantum dot reflective layer 2, and dry it to the final shape.

Embodiment 2

[0075] 1. Preparation of quantum dot dispersion

[0076] Quantitative red light quantum dots and dispersant were weighed and dissolved in cyclohexane solution, ultrasonicated and vibrated until the quantum dots were dissolved. Then stir the dispersion until uniformly dispersed for use.

[0077] 2. Preparation of quantum dot reflective adhesive

[0078] Add the quantum dot dispersion to the high-speed stirring silica gel quantitatively at a uniform speed, and continue stirring until fully dispersed.

[0079] 3. Molding

[0080] After devolatilizing the residual organic solvent, print the quantum dot reflective glue on the surface of the paper to form the quantum dot reflective layer 2; finally, cure the protective layer 3 on the surface of the cured quantum dot reflective layer 2, and dry it to the final shape.

Embodiment 3

[0082] 1. Preparation of quantum dot dispersion

[0083] Weigh red, green photon quantum dots and dispersant in a mass ratio of 5:3 and dissolve them in cyclohexane solution, sonicate and vibrate until the quantum dots dissolve. Then stir the dispersion until uniformly dispersed for use.

[0084] 2. Preparation of quantum dot reflective adhesive

[0085] Add the quantum dot dispersion liquid to the high-speed stirring polyurethane quantitatively at a uniform speed, and continue stirring until fully dispersed.

[0086] 3. Molding

[0087] After devolatilizing the residual organic solvent, sputter the quantum dot reflective glue on the surface of PE to form the quantum dot reflective layer 2; finally, cure the protective layer 3 on the surface of the cured quantum dot reflective layer 2, and dry it to the final shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com