Fully-degradable high-barrier co-extrusion bag and preparation method thereof

A high-barrier, fully-degradable technology, used in chemical instruments and methods, bag making operations, flexible container manufacturing, etc. Pollution and other problems, to achieve the effect of low production cost, ensure barrier properties and puncture strength, and avoid white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

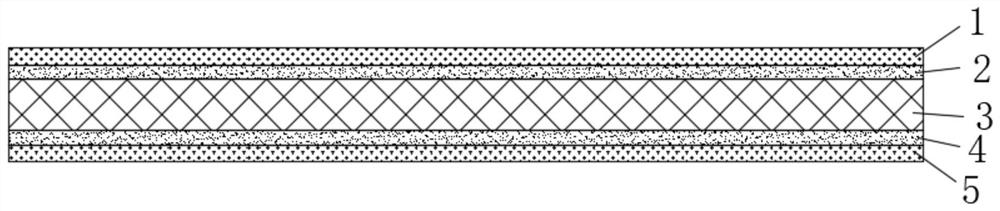

[0038] like figure 1 As shown, a fully degradable high-barrier co-extrusion bag includes a bag body, and the bag body is made of two pieces of co-extrusion film heat-pressed and edge-sealed. The co-extrusion film includes a PLA surface layer 1, a first removable A degradable adhesive layer 2, a barrier layer 3, a second degradable adhesive layer 4 and a PLA sealing layer 5, the barrier layer 3 is a PVOH modified EVOH material layer.

[0039] The raw material of the PLA surface layer 1 and the raw material of the PLA sealing layer 5 all adopt a density of 1.24g / cm 3 , and polylactic acid with a melt index of 18g / 10min under the condition of 210°C / 2.16kg load.

[0040] The raw materials of the first degradable adhesive layer 2 and the second degradable adhesive layer 4 are made of polylactic acid, maleic anhydride modified polylactic acid and maleic anhydride grafted polyethylene in a weight ratio of 7:2.5: 1 blended.

[0041] The maleic anhydride grafted polyethylene is sele...

Embodiment 2

[0055] A fully degradable high-barrier co-extruded bag, including a bag body, the bag body is made of two co-extruded films heat-pressed and edge-sealed, and the co-extruded film includes a PLA surface layer and a first degradable adhesive layer arranged in sequence , a barrier layer, a second degradable adhesive layer and a PLA sealing layer, wherein the barrier layer is a PVOH modified EVOH material layer.

[0056] The raw material of the PLA surface layer and the raw material of the PLA sealing layer all adopt a density of 1.22g / cm 3 , and polylactic acid with a melt index of 14g / 10min under the condition of 210°C / 2.16kg load.

[0057] The raw materials of the first degradable adhesive layer and the second degradable adhesive layer are mixed by polylactic acid, maleic anhydride modified polylactic acid and maleic anhydride grafted polyethylene in a weight ratio of 7:2:1 made.

[0058] The maleic anhydride grafted polyethylene is selected from PE1040, and the polylactic ac...

Embodiment 3

[0072] A fully degradable high-barrier co-extruded bag, including a bag body, the bag body is made of two co-extruded films heat-pressed and edge-sealed, and the co-extruded film includes a PLA surface layer and a first degradable adhesive layer arranged in sequence , a barrier layer, a second degradable adhesive layer and a PLA sealing layer, wherein the barrier layer is a PVOH modified EVOH material layer.

[0073] The raw material of the PLA surface layer and the raw material of the PLA sealing layer all adopt a density of 1.25g / cm 3 , and polylactic acid with a melt index of 22g / 10min under the condition of 210°C / 2.16kg load.

[0074] The raw materials of the first degradable adhesive layer and the second degradable adhesive layer are mixed by polylactic acid, maleic anhydride modified polylactic acid and maleic anhydride grafted polyethylene in a weight ratio of 7:3:1 made.

[0075] The maleic anhydride grafted polyethylene is selected from AT2235E, and the polylactic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com