High-temperature anhydrite sand-free self-leveling mortar and preparation method thereof

A technology of self-leveling mortar and anhydrous gypsum, which is applied in the field of building materials, can solve the problems of restricting the application and development of gypsum self-leveling mortar, easy delamination of gypsum self-leveling slurry, and poor construction reliability, so as to achieve easy construction, fast operation, and realization Reuse of resources and high fire rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

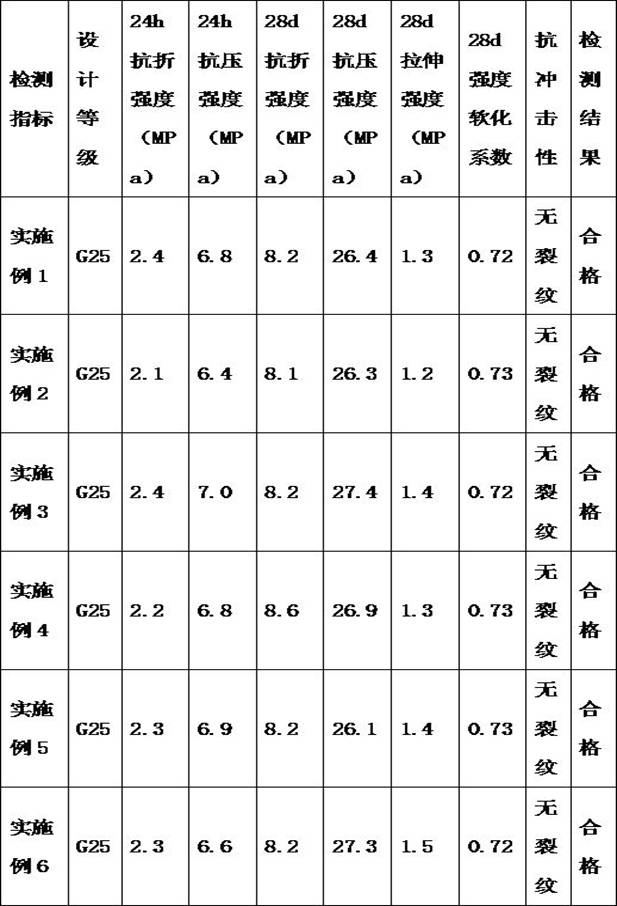

Examples

Embodiment 1

[0023] The invention provides a high-temperature anhydrous gypsum sand-free self-leveling mortar, which includes high-temperature anhydrite, admixture, water, fiber, and gypsum plastic stabilizer. The mass fractions of each component are: high-temperature anhydrous gypsum 50, fiber 0.05, cement 2.5, silica fume 2.5, mineral powder 2.5, water 17.5, gypsum plastic stabilizer 1, the water meets the water requirements for concrete mixing, and the gypsum plastic stabilizer is a commercially available product.

[0024] The high-temperature anhydrous gypsum is a mixed-phase anhydrous gypsum prepared by heating and calcining dihydrate phosphogypsum at high temperature to lose water.

[0025] In a further embodiment, the admixture is set as a cementitious material for concrete that meets the requirements of the national standard, and the admixture is set as one of Portland cement, fly ash, silica fume, ground steel slag powder, ore powder. one or more mixtures.

[0026] In a further e...

Embodiment 2

[0035] The invention provides a high-temperature anhydrous gypsum sand-free self-leveling mortar, which includes high-temperature anhydrite, admixture, water, fiber, and gypsum plastic stabilizer. The mass fractions of each component are: high-temperature anhydrous gypsum 50, fiber 0.05, cement 5, steel powder slag 1, mineral powder 2.5, water 20, gypsum plastic stabilizer 1, the water meets the water requirements for concrete mixing, and the gypsum plastic stabilizer is a commercially available product.

[0036] The high-temperature anhydrous gypsum is a mixed-phase anhydrous gypsum prepared by heating and calcining dihydrate phosphogypsum at high temperature to lose water.

[0037] In a further embodiment, the admixture is set as a cementitious material for concrete that meets the requirements of the national standard, and the admixture is set as one of Portland cement, fly ash, silica fume, ground steel slag powder, ore powder. one or more mixtures.

[0038] In a further e...

Embodiment 3

[0047] The invention provides a high-temperature anhydrous gypsum sand-free self-leveling mortar, which includes high-temperature anhydrite, admixture, water, fiber, and gypsum plastic stabilizer. The mass fractions of each component are: high-temperature anhydrous gypsum 50, fiber 0.05, cement 7.5, steel powder slag 1, fly ash 2.5, water 20, gypsum plastic stabilizer 1, the water meets the water requirements for concrete mixing, and the gypsum plastic stabilizer is a commercially available product.

[0048] The high-temperature anhydrous gypsum is a mixed-phase anhydrous gypsum prepared by heating and calcining dihydrate phosphogypsum at high temperature to lose water.

[0049] In a further embodiment, the admixture is set as a cementitious material for concrete that meets the requirements of the national standard, and the admixture is set as one of Portland cement, fly ash, silica fume, ground steel slag powder, ore powder. one or more mixtures.

[0050] In a further embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com