Rubber composition, preparation method thereof and run-flat tire inner support

A technology for run-flat tires and rubber compositions, applied in the fields of rubber compositions and tire rubber compositions, can solve the problem of low hysteresis and processability, heat resistance, low hysteresis loss, and inability to take into account the resistance to low hysteresis. Heat resistance and other problems, to achieve the effect of low mechanical strength, low hysteresis, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

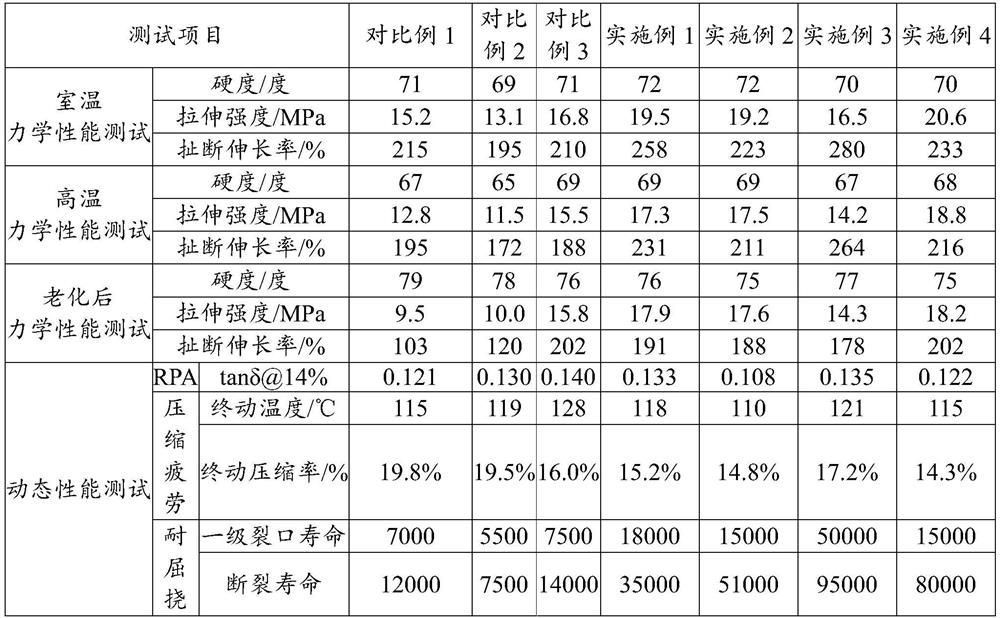

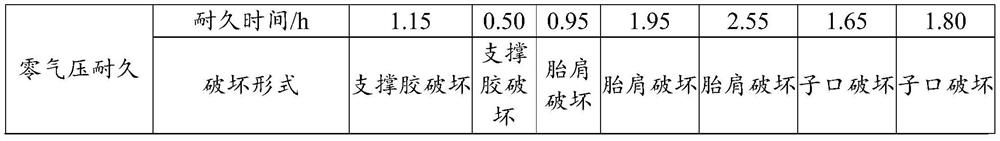

Examples

preparation example Construction

[0037] Another aspect of the present invention provides a method for preparing the rubber composition according to any of the above technical solutions, comprising the following steps:

[0038] One-stage mixing: add the low-cis-polybutadiene rubber, high-dispersion white carbon black, silane coupling agent and 1 / 2 carbon black into the closed rubber mixer according to the ratio of parts by weight, and mix Evenly discharge the glue to get a piece of masterbatch;

[0039] Two-stage mixing: according to the ratio of parts by weight, the hydrogenated modified block-type integrated rubber is added to the closed rubber mixer and masticated, and then the one-stage masterbatch, filler dispersant, anti-aging agent, activation agent and the remaining 1 / 2 of carbon black, after mixing evenly, discharge the glue to obtain the second-stage masterbatch;

[0040] Three-stage mixing: Add the two-stage masterbatch, insoluble sulfur, accelerator and anti-reversion agent into a closed rubber mi...

Embodiment 1

[0045] This embodiment provides a high heat-resistant run-flat tire inner support rubber composition and a preparation method thereof, specifically:

[0046] The inner support rubber composition formula, in parts by weight, includes the following components:

[0047] Hydrogenated modified block type integrated rubber 60 parts, low cis polybutadiene rubber 40 parts, N550 carbon black 35 parts, 1115MP white carbon black 20 parts, TESPT silane coupling agent 2.4 parts, SL5050 filler dispersant 2 parts , 3.5 parts of anti-aging agent, 5 parts of activator, 1.6 parts of insoluble sulfur, 1.5 parts of NS accelerator, 1 part of TBzTD anti-reversion agent.

[0048] Among them, the weight-average molecular weight of hydrogenated modified block-type integrated rubber is 650,000, and the hydrogenation degree of double bonds is 92%. The integrated rubber before hydrogenation has a linear tri-block structure: both ends are randomly copolymerized styrene-butadiene rubber segments, It accou...

Embodiment 2

[0059] This embodiment provides a high heat-resistant run-flat tire inner support rubber composition and a preparation method thereof, specifically:

[0060] The inner support rubber composition formula, in parts by weight, includes the following components:

[0061] 60 parts of hydrogenated modified block-type integrated rubber, 40 parts of low-cis polybutadiene rubber, 25 parts of BC2123 carbon black, 25 parts of 1085MP white carbon black, 2 parts of NXT silane coupling agent, AEO-9 filler dispersant 2 parts, 3.5 parts of anti-aging agent, 5 parts of activator, 1.6 parts of insoluble sulfur, 1.5 parts of NS accelerator, 1 part of WY9188 anti-reversion agent.

[0062] Among them, the molecular structures of hydrogenated modified block-type integrated rubber and low-cis polybutadiene rubber are the same as those in Example 1.

[0063] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com