High-entropy alloy film capable of quantitatively controlling gradient change of element content and preparation method

A technology of element content and gradient change, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve problems such as limited research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 5-element high-entropy alloy thin film composed of CrMnFeCoNi was prepared on a silicon substrate by intermittent magnetron sputtering. Simultaneously control the RF power supply and the DC power supply to sputter CrMnFeCoNi high-entropy alloy targets and pure manganese metal targets with nearly equiatomic ratio. To 0W, sputtering 4 times, the single sputtering time is 60min, the intermittent time is 20min, a total of 5.3 hours.

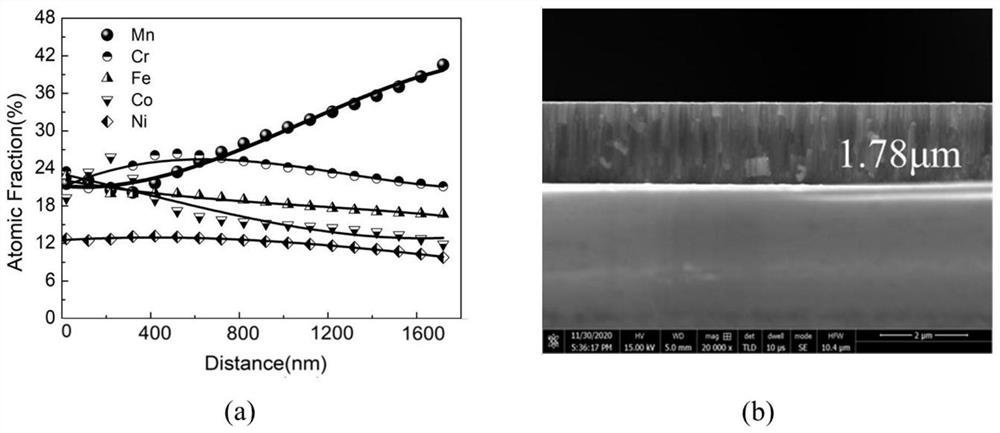

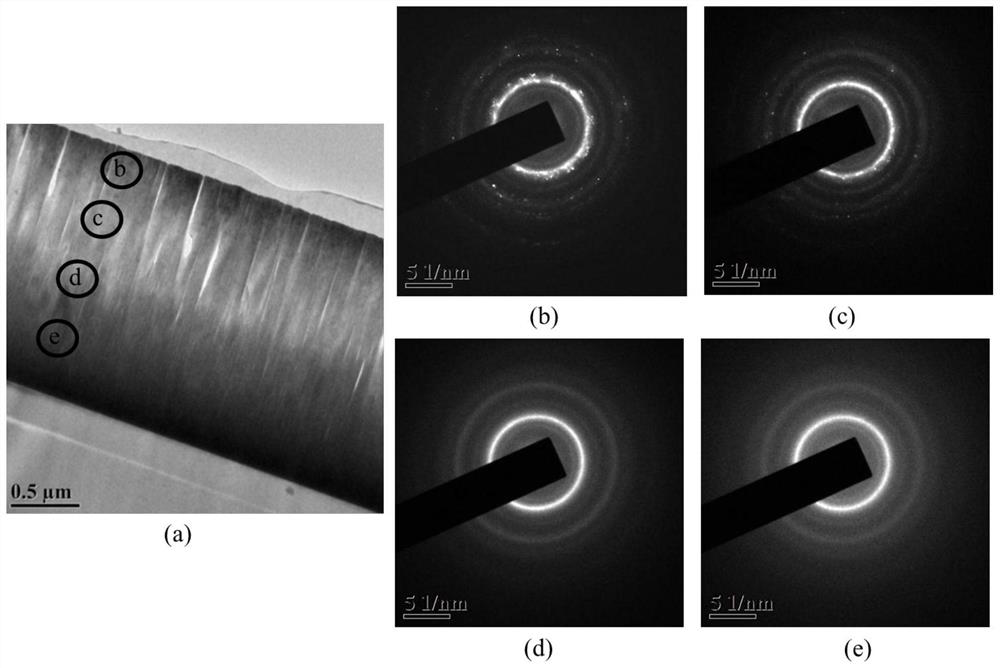

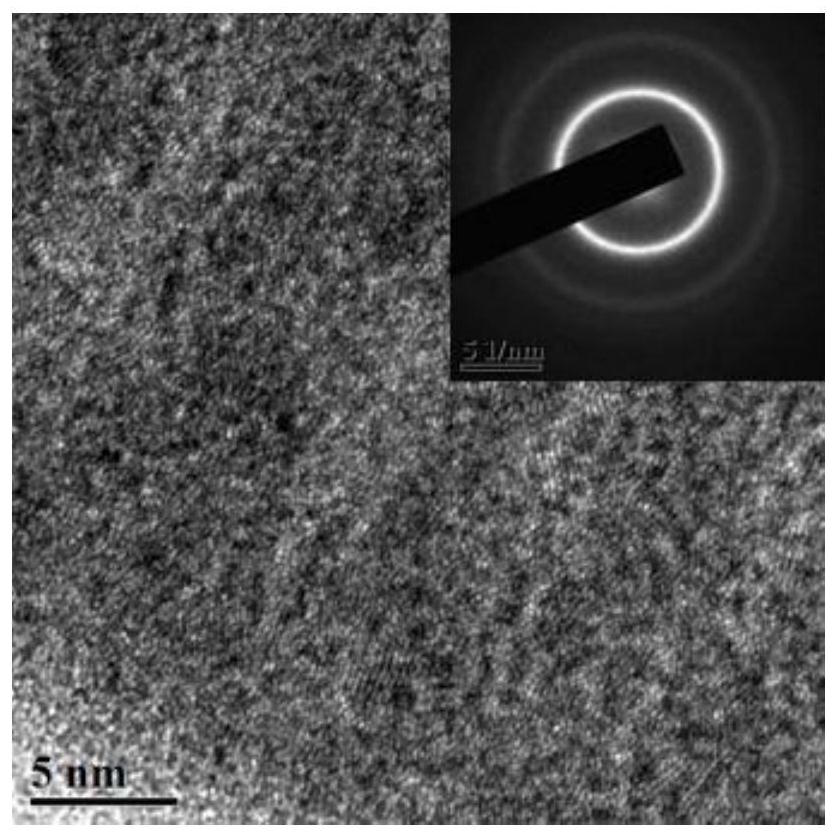

[0040] Gained high-entropy alloy thin film SEM test results are as follows figure 1 As shown, the results show that among the five elements, the content of manganese varies from 20at% to 42at%, while the content of the other four elements varies relatively little, and the total thickness of the high-entropy alloy film is 1.78μm. And the change of content gradient also caused the change of structure ( figure 2 ), the film structure evolves from the nanocrystalline structure on the surface to the amorphous structure inside. That is to say,...

Embodiment 2

[0042] Through intermittent magnetron sputtering, the radio frequency power supply and the DC power supply are simultaneously controlled to sputter the nearly equiatomic ratio CrMnFeCoNi high-entropy alloy target and pure manganese metal target. The power of the radio frequency power supply is fixed at 110W, and the power of the DC power supply is from 30W. Decrease to 0W at a speed of 7-8W each time, and sputter 5 times, with a single sputtering time of 30 minutes and an intermittent time of 15 minutes, a total of 3.75 hours. The film thickness was 1.72 μm. The high-entropy alloy thin film has a structure in which the manganese content changes gradually. Compared with other high-entropy alloy thin films, the thin film prepared by the method has both nanocrystalline and amorphous structures, and is a composite material.

Embodiment 3

[0044] The nearly equiatomic CrMnFeCoNi high-entropy alloy target and pure manganese metal target are sputtered by simultaneously controlling the radio frequency power supply and the direct current power supply in magnetron sputtering. The power of the RF power supply was fixed at 130W, and the power of the DC power supply was reduced from 30W at a rate of 6-7W each time. Sputtering was done 4 times, with a single sputtering time of 60 minutes and an intermittent time of 20 minutes, totaling 5.3 hours. The film thickness is about 2 μm. The film prepared by the invention has the characteristic of manganese element content gradient. Because the composition determines the structural characteristics of the film, more structural information can be found in films with varying content, which can be used as a method for high-throughput experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com