Water-based paint production equipment

A technology for water-based paint and production equipment, applied in the directions of dissolving, mixer, chemical instruments and methods, etc., can solve the problem of finishing integration, pulverization and stirring of paint raw materials, etc. Processing and other problems, to achieve the effect of maintaining integrity, good stirring effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

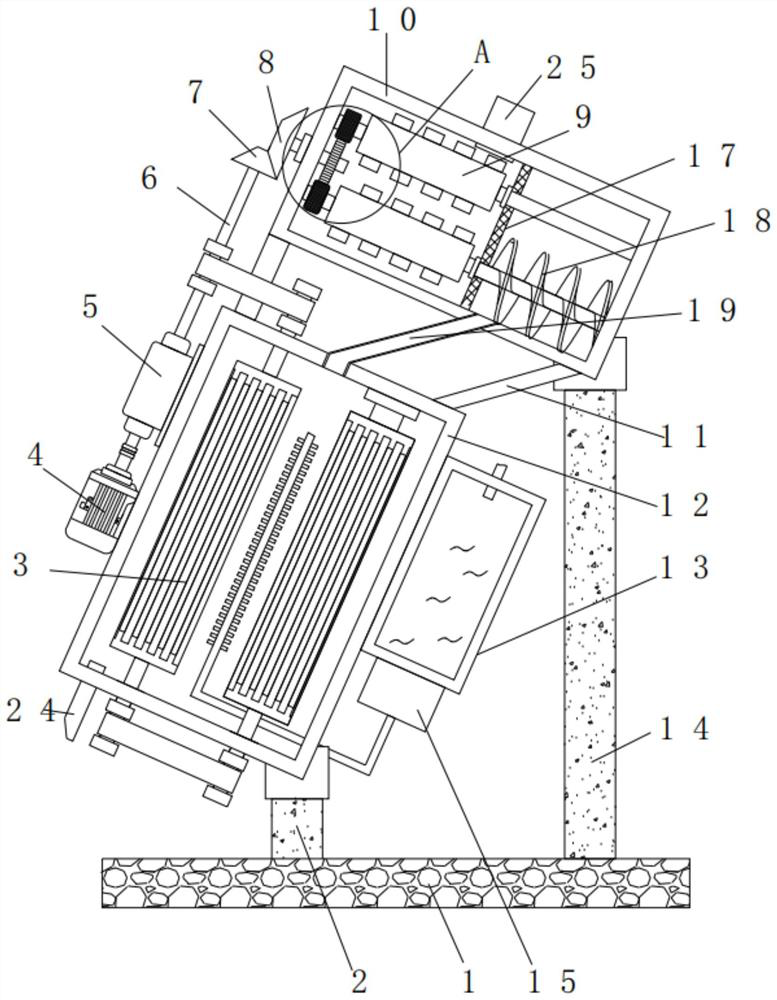

[0030] Embodiment 1: a kind of water-based paint production equipment that the present invention proposes, comprises installation base 1, and the top left side of installation base 1 is welded with first support bar 2, and the top of first support bar 2 is welded with second box body 12, On the left side of the second box body 12, a motor 4 is fixedly connected by bolts, and the top left side of the second box body 12 is fixedly connected with a gearbox 5 by screws. , the output end of the motor 4 is welded to the input end of the gearbox 5, the output end of the gearbox 5 is welded with a transmission rod 6, and the end of the transmission rod 6 away from the gearbox 5 is welded with a first bevel gear 7, and the top right of the installation base 1 The side is welded with a second support bar 14, and the top of the second support bar 14 is welded with a first box body 10, and the first box body 10 is provided with a partition net 17, and the first box body 10 of the partition...

Embodiment 2

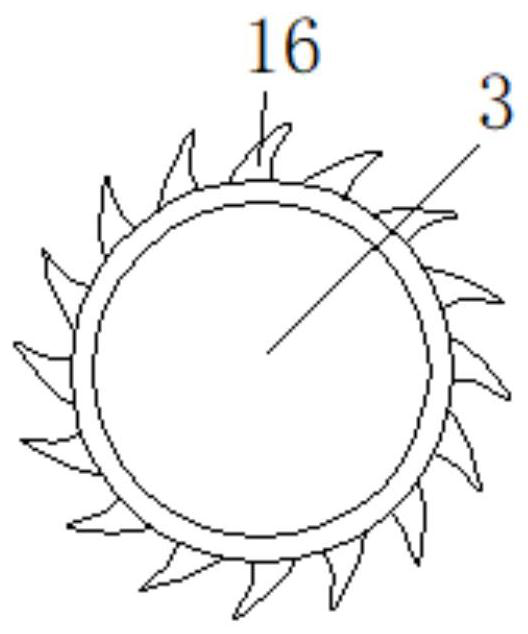

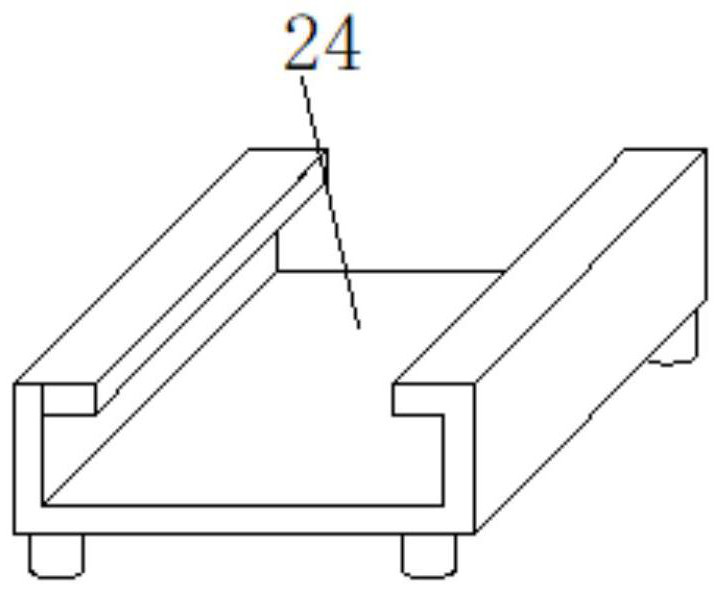

[0031] Embodiment 2: The inner cavity of the second box body 12 is rotatably connected with a stirring rod 3 that penetrates and extends outside the second box body 12, and the outer ring of one end of the stirring rod 3 located at the bottom of the second box body 12 is welded with a first a belt roller. , the first belt roller is connected by the first belt, the outer ring of the left stirring rod 3 located outside the second box 12 is welded with the second belt roller, the outer ring of the transmission rod 6 is welded with the fourth belt roller, and the fourth belt The roller is connected with the third belt roller through the second belt, and the outer ring of the stirring rod 3 is welded with a plurality of stirring blades 16, and the left side of the bottom of the second box body 12 is provided with a mounting hole, and a discharge trough 24 is arranged in the mounting hole. , the right side of the second box 12 is welded with a water tank 13, the bottom of the water ...

Embodiment 3

[0032]Embodiment 3: Both sides of the top of the second box 12 are welded with fixed rods 11, the top of the fixed rods 11 is welded to the bottom of the first box 10, and the middle of the outer ring of the second rotating rod 20 is welded with a crushing rod 9 The outer ring of the crushing rod 9 is uniformly welded with a plurality of crushing blades, the left side of the outer ring of the second rotating rod 20 is welded with a first gear 21, the left side of the first box body 10 is provided with a first through hole, the first A rotating shaft 22 is fixedly connected to the through hole, and a second gear 23 is welded to the outer ring of one end of the rotating shaft 22 located in the first casing 10 , and the second gear 23 meshes with the rotating shaft 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com