Anti-explosion and anti-impact grouting material and preparation method thereof

A kind of grouting material and impact resistance technology, applied in the field of anti-knock and impact-resistant grouting material and its preparation, which can solve the problems of burst damage, loss of bearing capacity, high brittleness of high-strength and ultra-high-strength grouting materials, and achieve the effect of high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

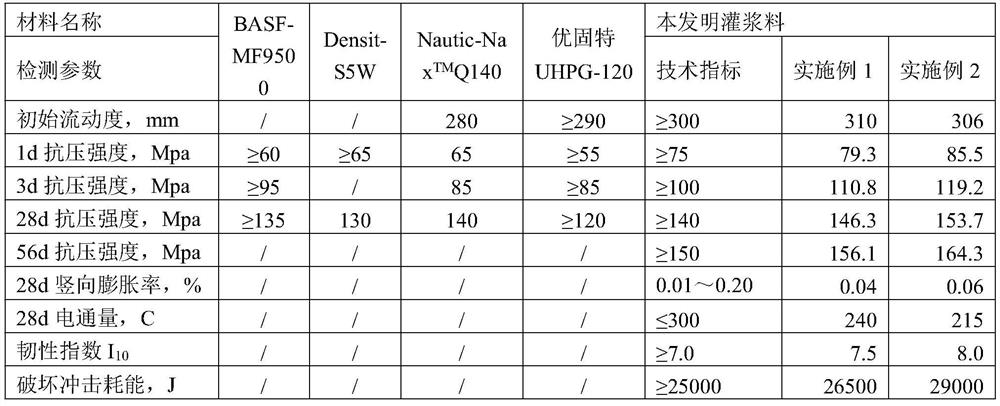

Examples

Embodiment 1

[0037] Example 1 Preparation of a kind of anti-knock and anti-shock grouting material 1

[0038] An anti-explosion and impact-resistant grouting material 1, the composition and mass percentage of the grouting material are: 45% of composite cementitious material, 55% of sand blending, 1.45% of mixed admixture (accounting for the mass percentage of composite cementitious material), Tough material (volume ratio) 0.80%. in:

[0039] 1) The composition of the composite cementitious material is: 75% of PI525 cement, 15% of microbeads, 4% of silica fume, and 6% of hardening expansion agent.

[0040] 2) The composition of sand preparation is: 8% of 6-8 mesh, 10% of 8-10 mesh, 25% of 10-20 mesh, 19% of 20-40 mesh, 17% of 40-70 mesh, 12% of 70-120 mesh, 120-200 mesh 9%.

[0041] 3) The composition of the blended admixture (accounting for the mass percentage of the composite gelling material) is 0.50% of the water reducer, 0.02% of the retarder, 0.40% of the defoamer, 0.50% of the pol...

Embodiment 2

[0045] Embodiment 2 Preparation of a kind of anti-knock and anti-shock grouting material 2

[0046] An anti-explosion and impact-resistant grouting material 2, the composition and mass percentage of the grouting material are: 50% of composite cementitious material, 50% of sand blending, 1.65% of mixed admixture (accounting for the mass percentage of composite cementitious material), Tough material (volume ratio) 1.20%. in:

[0047] 1) The composition of the composite cementitious material is: 70% of PI625 cement, 18% of microbeads, 6% of silica fume, and 6% of hardening expansion agent.

[0048] 2) The composition of sand preparation is: 8% of 6-8 mesh, 10% of 8-10 mesh, 25% of 10-20 mesh, 19% of 20-40 mesh, 17% of 40-70 mesh, 12% of 70-120 mesh, 120-200 mesh 9%.

[0049] 3) The composition of the blended admixture (accounting for the mass percentage of the composite gelling material) is 0.70% of the water reducer, 0.01% of the retarder, 0.50% of the defoamer, 0.50% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com