Preparation method of electromagnetic wave-transparent concrete

A concrete and wave-transmitting technology is applied in the field of electromagnetic wave-transmitting concrete preparation to achieve the effects of improving electromagnetic wave transmittance, increasing strength, and improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

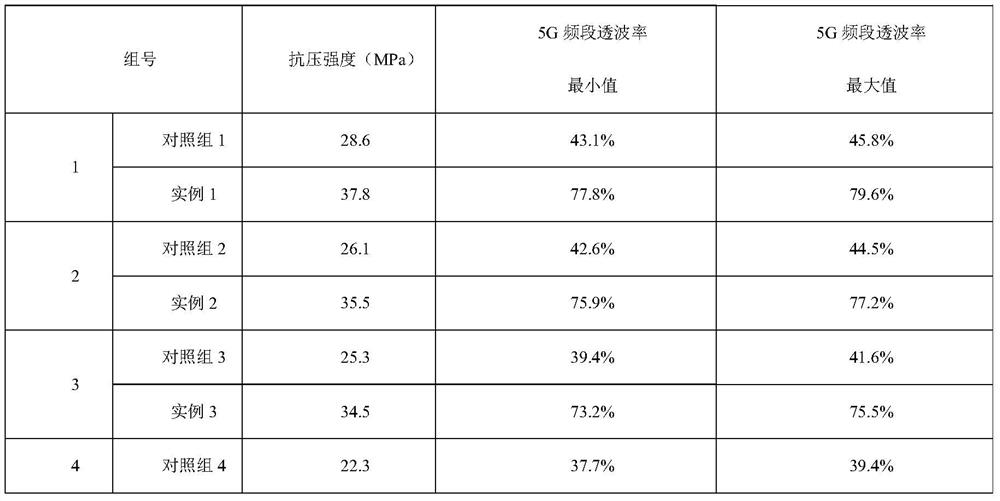

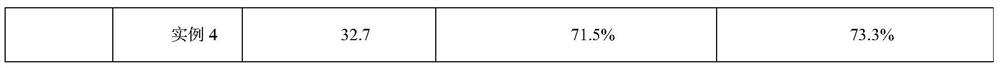

Examples

example 1

[0037] 1. The main components of concrete:

[0038] (1) The mass ratio of water to PO 42.5 ordinary Portland cement is 0.15;

[0039] (2) The mass ratio of PO 42.5 ordinary Portland cement to the main constituent materials of concrete is 15%;

[0040] (3) The mass ratio of fine aggregate to the main constituent materials of concrete is 33%;

[0041] (4) The mass ratio of composite coarse aggregate to the main constituent materials of concrete is 52%;

[0042] 2. Wave penetration enhancer

[0043] (1) The mass ratio of polycarboxylate water-reducing and PO.42.5 ordinary Portland cement is 0.5%;

[0044] (2) the mass ratio of sodium linear alkylbenzene sulfonate and PO.42.5 ordinary Portland cement is 1%;

[0045] (3) The mass ratio of aluminum dihydrogen phosphate and PO.42.5 ordinary Portland cement is 1%;

[0046] (4) the mass ratio of nano silicon nitride and PO 42.5 ordinary portland cement is 0.5%;

[0047] 3. Aggregate treatment agent

[0048] (1) The mass percenta...

example 2

[0060] 1. The main components of concrete:

[0061] (1) The mass ratio of water to PO 42.5 ordinary Portland cement is 0.17;

[0062] (2) The mass ratio of PO 42.5 ordinary Portland cement to the main constituent materials of concrete is 17%;

[0063] (3) The mass ratio of fine aggregate to the main constituent materials of concrete is 36%;

[0064] (4) The mass ratio of composite coarse aggregate to the main constituent materials of concrete is 47%;

[0065] 2. Wave penetration enhancer

[0066] (1) The mass ratio of polycarboxylate water reduction and PO 42.5 ordinary Portland cement is 0.7%;

[0067] (2) the mass ratio of sodium linear alkylbenzene sulfonate and PO 42.5 ordinary Portland cement is 1.4%;

[0068] (3) The mass ratio of aluminum dihydrogen phosphate and PO 42.5 ordinary Portland cement is 1.4%;

[0069] (4) the mass ratio of nano silicon nitride and PO 42.5 ordinary Portland cement is 0.9%;

[0070] 3. Aggregate treatment agent

[0071] (1) The mass per...

example 3

[0083] 1. The main components of concrete:

[0084] (1) The mass ratio of water to PO 42.5 ordinary Portland cement is 0.18;

[0085] (2) The mass ratio of PO 42.5 ordinary Portland cement to the main constituent materials of concrete is 18%;

[0086] (3) The mass ratio of fine aggregate to the main constituent materials of concrete is 38%;

[0087] (4) The mass ratio of composite coarse aggregate to the main constituent materials of concrete is 44%;

[0088] 2. Wave penetration enhancer

[0089] (1) The mass ratio of polycarboxylate water reduction and PO 42.5 ordinary Portland cement is 0.8%;

[0090] (2) the mass ratio of sodium linear alkylbenzene sulfonate and PO 42.5 ordinary Portland cement is 1.6%;

[0091] (3) The mass ratio of aluminum dihydrogen phosphate and PO 42.5 ordinary Portland cement is 1.6%;

[0092] (4) the mass ratio of nano silicon nitride and PO 42.5 ordinary portland cement is 1.2%;

[0093] 3. Aggregate treatment agent

[0094] (1) The mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com