Polypropylene composite material with high elongation at break and scratch resistance and preparation method thereof

A composite material, polypropylene technology, applied in the field of modified polymer materials, can solve the problems of poor scratch resistance, reduced elongation at break, low surface hardness of polypropylene, etc., to improve the scratch resistance effect, improve the Scratch resistance, the effect of improving elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

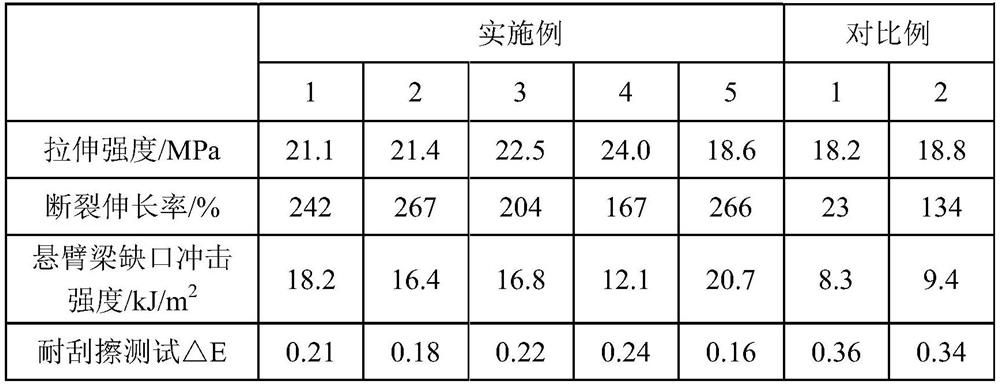

Examples

Embodiment 1

[0016] Weigh 87.4 parts of polypropylene PP K7227H (Wuhan ethylene), 6 parts of toughening agent POE 8137 (Dow Chemical), 3 parts of ultra-high molecular weight polyethylene Lupolen UHM 5000 (Basel), anti-scratch agent AntiScratch 100 (Degus Sai) 3 parts, lubricant A-C540 (Honeywell) 0.3 part, antioxidant 1010 (BASF) 0.1 part, antioxidant 168 (BASF) 0.2 part, placed in a high-speed mixer and mixed for 2 minutes to obtain a uniform dispersion The mixture, wherein, the speed of the high-speed mixer is 520rpm; The uniformly dispersed mixture obtained in the above steps is extruded and granulated by a twin-screw extruder with a length-to-diameter ratio of 48:1, and the twin-screw extruder The temperature of the machine from the feeding section to the machine head is 170°C, 195°C, 195°C, 200°C, 200°C, 200°C, 195°C, 195°C, 195°C, 200°C, and the feeding speed is 40rpm. The speed is 560rpm. That is a high elongation at break, scratch-resistant polypropylene composite material.

Embodiment 2

[0018] Weigh 88.4 parts of polypropylene PP K7726H (Yanshan Petrochemical), 4 parts of toughening agent POE 8200 (Dow Chemical), 3 parts of ultra-high molecular weight polyethylene UHMWPE 240M (Mitsui Chemicals), 3 parts of anti-scratch agent LYSI-306 (Chengdu Si Like) 4 parts, lubricant A-C540 (Honeywell) 0.3 part, antioxidant 1010 (Shandong Sanfeng) 0.1 part, antioxidant 168 (Shandong Sanfeng) 0.2 part and mix in a high-speed mixer 3min to obtain a uniformly dispersed mixture, wherein the speed of the high-speed mixer is 480rpm; the uniformly dispersed mixture obtained in the above steps is extruded and granulated by a twin-screw extruder with a length-to-diameter ratio of 46:1. The temperature of the screw extruder from the feeding section to the machine head is 170°C, 195°C, 195°C, 200°C, 200°C, 200°C, 195°C, 195°C, 195°C, 200°C, and the feeding speed is 35rpm , The extrusion speed is 580rpm. That is, a high elongation at break and scratch-resistant polypropylene composit...

Embodiment 3

[0020] Weigh 87.5 parts of polypropylene PP BX3800 (Korea SK), 5 parts of toughening agent POE 8842 (Dow Chemical), 4 parts of ultra-high molecular weight polyethylene UHMWPE HL5010 (Formosa Plastics Chemical), and scratch-resistant agent LYSI-306 (Chengdu Silike) 3 parts, lubricant BS-2818 (Zhongshan Huamingtai Chemical Industry) 0.2 parts, antioxidant 168 (Shandong Sanfeng) 0.1 part, antioxidant 0.2 parts UV-3808PP5 (Swiss Ciba) in high speed Mix in a mixer for 3 minutes to obtain a uniformly dispersed mixture, wherein the speed of the high-speed mixer is 560 rpm; the uniformly dispersed mixture obtained in the above steps is extruded through a twin-screw extruder with an aspect ratio of 42:1 For granulation, the temperature of the twin-screw extruder from the feeding section to the head is 170°C, 195°C, 195°C, 200°C, 200°C, 200°C, 195°C, 195°C, 195°C, 200°C. The material rotation speed was 45 rpm and the extrusion rotation speed was 580 rpm. That is, a high elongation at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com