Coal mine underground drilling construction equipment system and construction parameter optimization method thereof

A technology for construction equipment and optimization methods, applied in drilling equipment and methods, mining equipment, drilling equipment, etc., can solve problems such as low degree of automation and intelligence, no general construction equipment, and inability to meet the needs of intelligent drilling construction, etc. Achieve high construction efficiency, reduce construction personnel, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

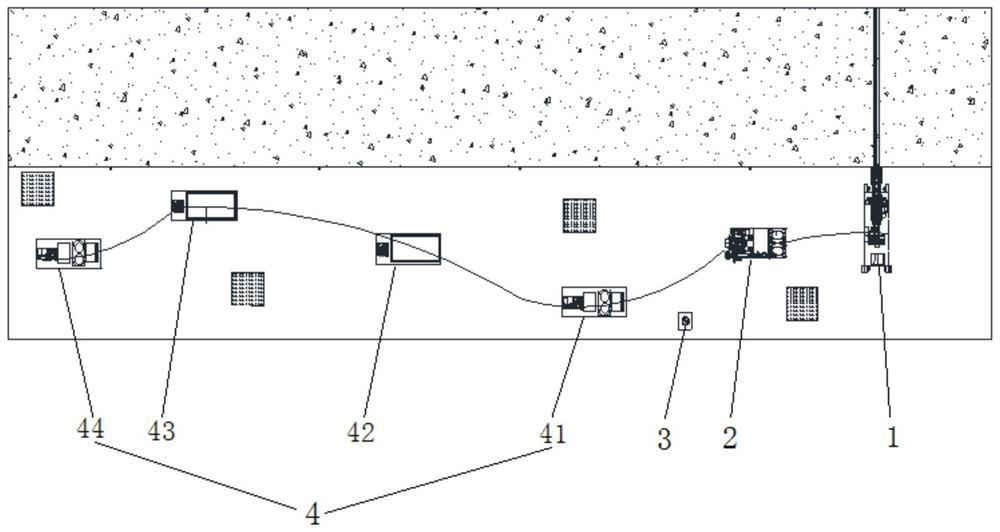

[0098] When the coal mine drilling construction equipment system conducts roadway inspection and the drilling unit 1 finds that the roadway construction area needs anchoring construction, the autonomous control method of the drilling construction equipment system is as follows:

[0099] Step 1: The intelligent decision-making system 3 comprehensively analyzes the roadway graphic information, roadway failure information and equipment operation information obtained by the detection device 5, filters and processes redundant information, and extracts the feature points of obstacles in the roadway graphic information and the sparse environment of the roadway area Information such as feature points, roadway surrounding rock bottom heave, edge position, roadway position to be repaired, and the operating parameters of each equipment in the construction equipment system are used to determine the anchoring construction range, anchor spacing, anchor length, anchor arrangement, anchoring ag...

Embodiment 2

[0107] When the coal mine drilling construction equipment system conducts roadway inspection and the drilling unit 1 finds that the roadway construction area needs grouting construction, the autonomous control method of the drilling construction equipment system is as follows:

[0108]Step 1: The intelligent decision-making system 3 comprehensively analyzes the roadway graphic information, roadway failure information and equipment operation information obtained by the detection device 5, filters and processes redundant information, and extracts the feature points of obstacles in the roadway graphic information and the sparse environment of the roadway area Determine the grouting construction scope, grouting method, surrounding rock strength requirements, grouting hole layout, grouting material types, etc. Information, according to the obstacle information parameter roadway area coordinate information parameters to reasonably determine the operation trajectory and optimized rout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com