Combined combustion stabilizer capable of separating thick pulverized coal and thin pulverized coal and controlling concentration

A combinatorial burner technology, which is applied in the direction of burners burning powder fuels, burning block fuels and powder fuels, burning liquid fuels and powder fuels, etc. Affect the economic benefits of the unit, large changes in coal quality, etc., to achieve the effect of improving oil-free peak shaving capability, controllable pulverized coal concentration, and strong combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of the solution of the present invention, the solution will be further elaborated below in conjunction with the accompanying drawings and through specific implementation methods.

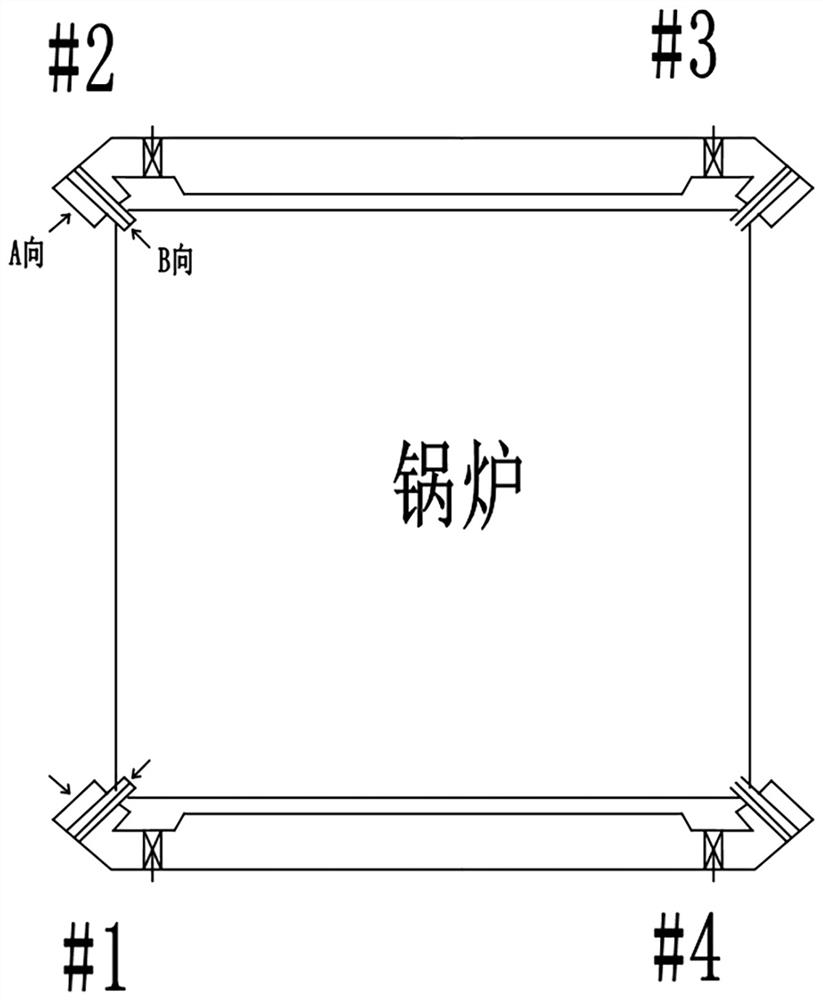

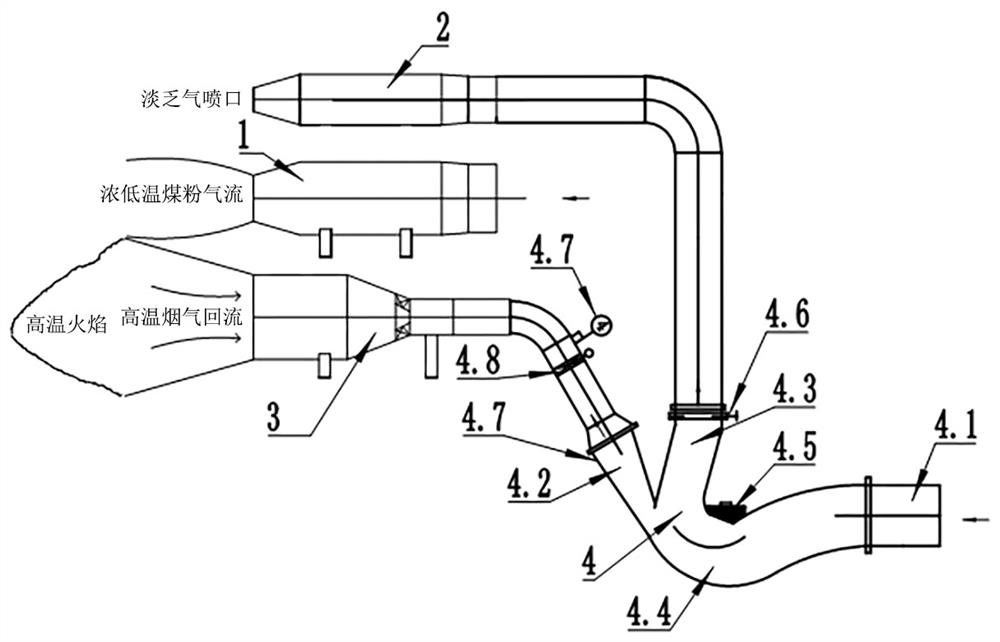

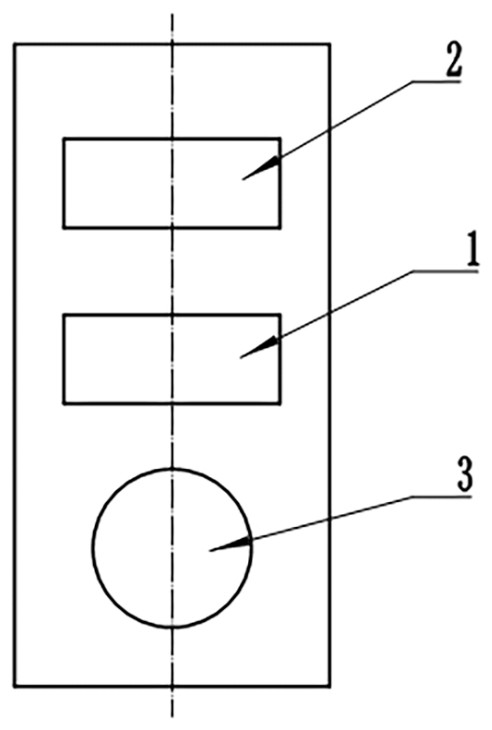

[0022] like Figure 1 to Figure 3 As shown in , there is provided a combined combustor with controllable concentration of pulverized coal thick and light separation, the stabilizer is located at the four corners of the four-corner tangential boiler, the stabilizer includes the first once-through burner 1, the The stabilizing burner also includes a second direct-flow burner 2 and a pre-chamber type swirl stabilizing burner 3, the coal of the pre-chamber type stabilizing burner 3, the first direct-flow burner 1 and the second direct-flow burner 2 The powder nozzles are arranged sequentially from bottom to top along the furnace, and the pulverized coal inlets of the pre-chamber type stabilizing burner 3 and the second once-through burner 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com