Wormwood raw material drying process and equipment

A drying process and drying equipment technology, which is applied in the direction of drying solid materials, dry goods handling, drying chamber/container, etc., can solve the problems of automatic removal of inconvenient impurities, difficult control of drying degree, etc., to achieve easy water content, easy control, and guarantee The effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

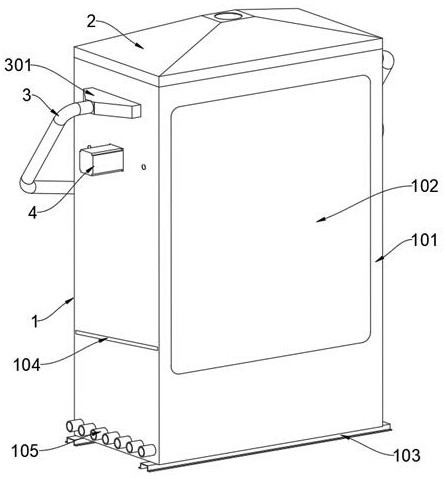

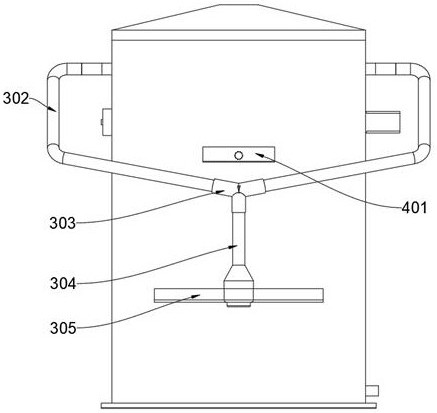

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0027] Both the vibration motor 107 (model JZO-50-4) and the transmission motor 407 (model YS7134) mentioned in the present invention can be purchased from the market or customized.

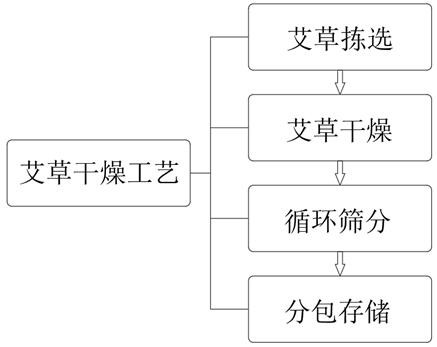

[0028] see Figure 1 to Figure 6 , a kind of embodiment provided by the invention: a kind of wormwood raw material drying process comprises the following steps:

[0029] Step 1: Sorting the wormwood, cutting and removing the picked wormwood according to avoid soil mixing, remove moldy and deteriorated wormwood leaves in the wormwood, make the wormwood more pure, and place it on the sorting operation table. Remove the stems and impurities, then put them in a clean and dry container, wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com