Lithium ion battery negative pole piece and preparation method and application thereof

A lithium-ion battery and negative pole piece technology, which is applied in the field of lithium-ion batteries, can solve problems affecting the design and performance of lithium-ion batteries, and limit use, so as to promote battery performance, increase energy density, and prevent expansion and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

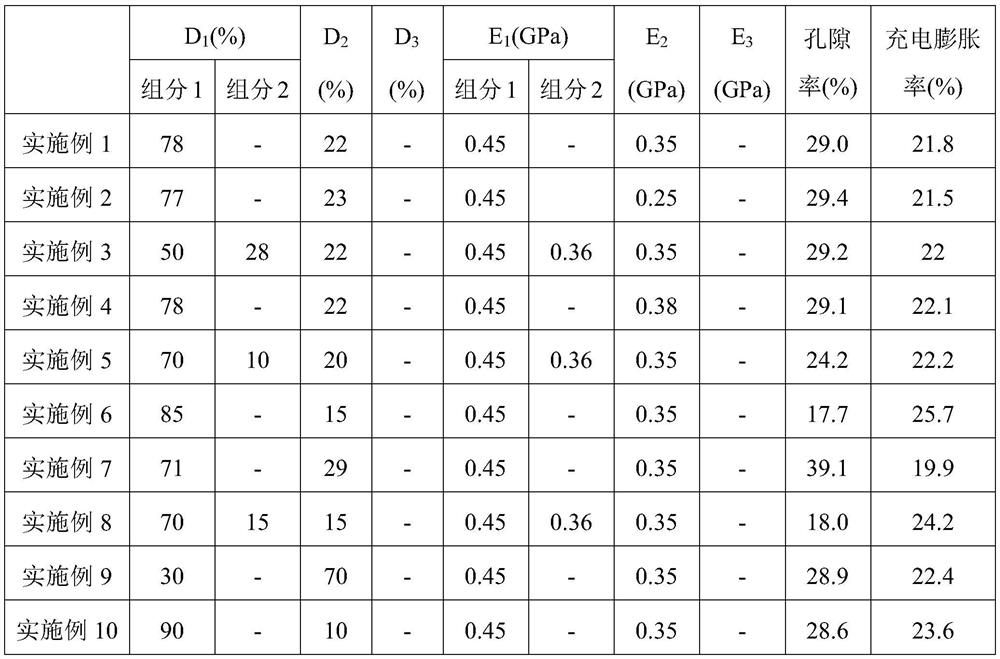

[0069] This embodiment provides a lithium ion battery negative pole piece, the lithium ion battery negative pole piece includes a first active material, a second active material, conductive carbon black and polyvinylidene fluoride; the first active material and the second active material The elastic modulus of the two active materials, and the volume percentage of the negative active material are as shown in Table 1, the elastic modulus of the first active material is 1.29 times the elastic modulus of the second active material, the first active material Particle size D of the active material 50 is 20 μm, the particle size D of the second active material 50 is 12 μm, the particle size D of the first active material and the second active material 50 The ratio is 1:0.6; the first active material is artificial graphite, and the second active material is natural graphite.

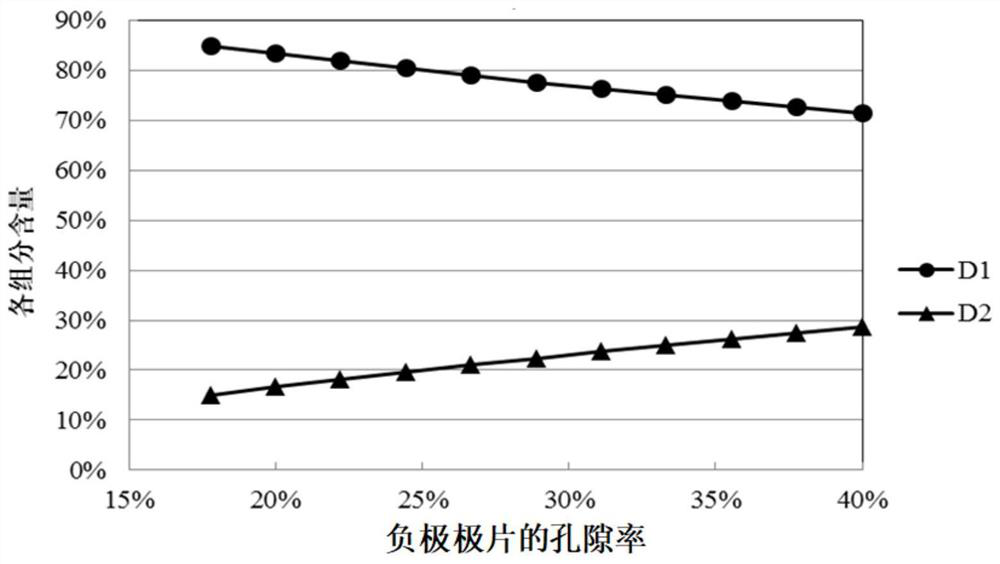

[0070] The porosity of the negative pole sheet of the lithium-ion battery is 29.0%, and the relationship b...

Embodiment 2

[0074] This embodiment provides a lithium-ion battery negative pole piece, the lithium-ion battery negative pole piece includes a first active material, a second active material, carbon nanotubes and styrene-butadiene rubber; the first active material and the second The modulus of elasticity of the active material and the volume percentage of the negative active material are shown in Table 1. The modulus of elasticity of the first active material is 1.8 times that of the second active material. Material particle size D 50 is 20 μm, the particle size D of the second active material 50 is 14 μm, the particle size D of the first active material and the second active material 50 The ratio is 1:0.7; the first active material is artificial graphite, and the second active material is natural graphite.

[0075] The porosity of the negative pole sheet of the lithium-ion battery is 29.4%, and the relationship between the porosity and the volume percentage of the negative active materi...

Embodiment 3

[0079] This embodiment provides a lithium-ion battery negative pole piece, the lithium-ion battery negative pole piece includes a first active material, a second active material, graphene and polyacrylic acid; the first active material and the second active material The modulus of elasticity and the volume percentage of the negative electrode active material are shown in Table 1, the modulus of elasticity of the first active material is 1.19 times that of the second active material, and the modulus of elasticity of the first active material is Particle size D 50 is 20 μm, the particle size D of the second active material 50 is 12 μm, the particle size D of the first active material and the second active material 50The ratio is 1:0.6; the first active material includes artificial graphite component 1 and natural graphite component 2, and the second active material is natural graphite.

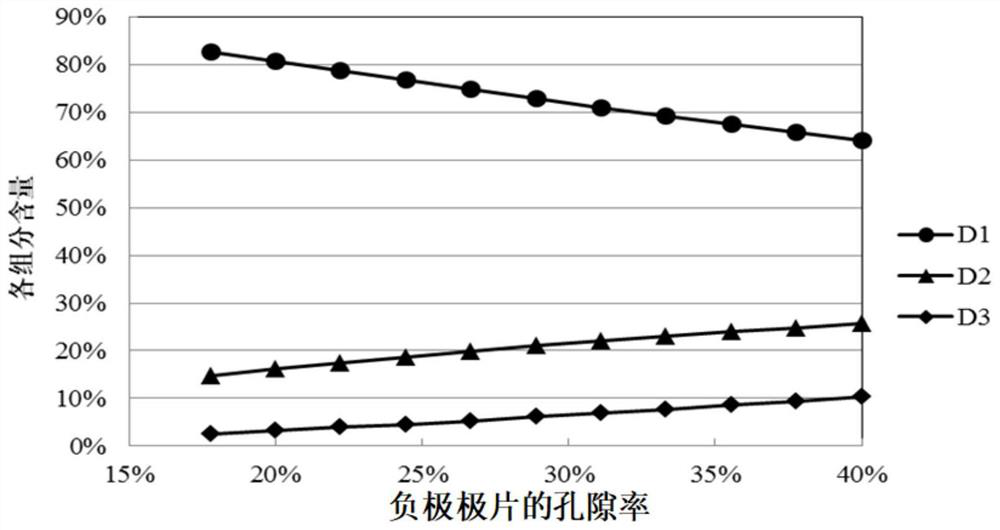

[0080] The porosity of the negative pole sheet of the lithium-ion battery is 29.2%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com