Method for carrying out patterning orientation on liquid crystal elastomer and preparation method of touch display device

A liquid crystal elastomer and patterning technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of complex process, high production cost of touch display devices, hindering the market application of touch display technology, etc., and achieve simplification of preparation process, Promoting market application and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

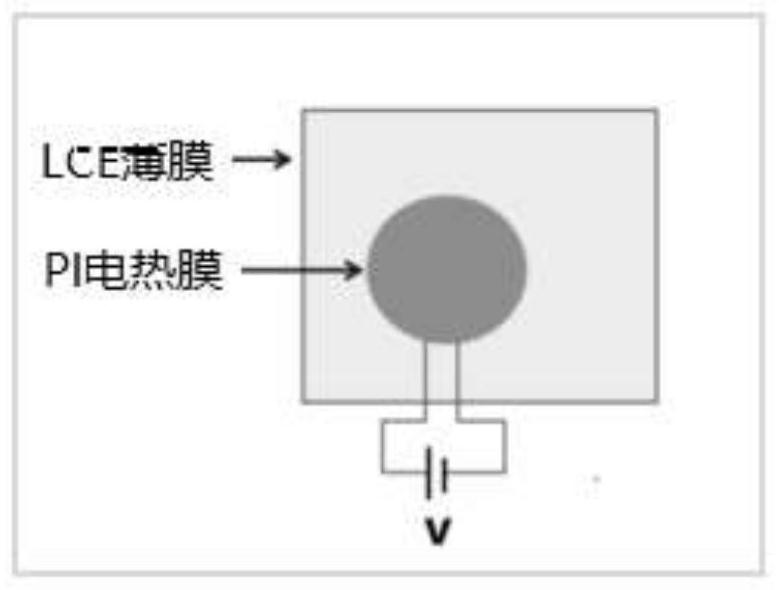

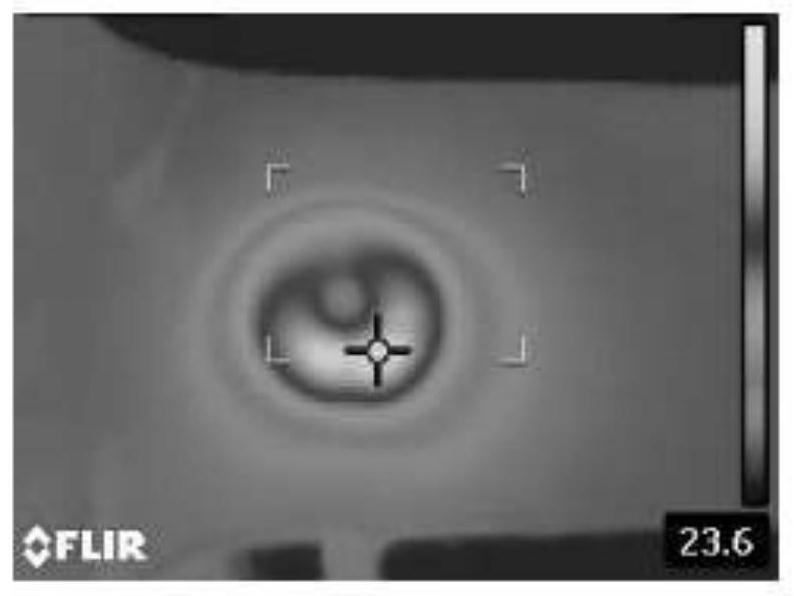

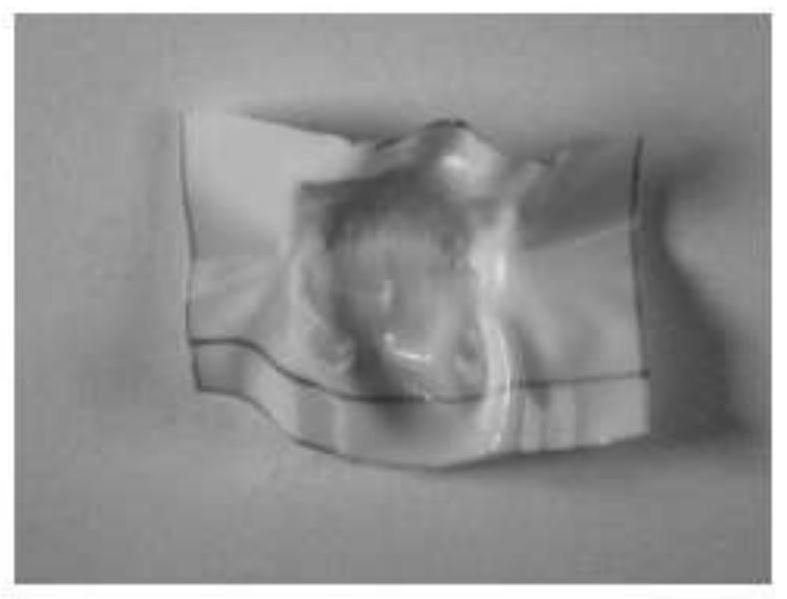

[0060] The second aspect of the present application provides a method for manufacturing a touch display device, the method comprising the following steps: S100, providing a liquid crystal elastomer with a cross-linked network structure containing dynamic covalent bonds, the liquid crystal elastomer having a single domain Protrusion; S200, applying electrothermal drive or photothermal drive to the protrusion, wherein the electrothermal drive method is to place a polyimide electrothermal film under the protrusion, and the photothermal drive method is to place The photothermal responsive material is doped in the protrusions; S300, heat-treating the protrusions, so that the dynamic covalent bonds in the protrusions undergo an exchange reaction to form a new cross-linked network structure and fix the orientation , forming protrusions with a fixed orientation; S400, adjusting the expansion and contraction parameters of each protrusion through the electrical processing control of the ...

Embodiment 1

[0086] (1) Preparation of liquid crystal elastomer samples

[0087] A mixture of 0.298 g (1 mmol) of epoxy resin mesogen p-diphenol diglycidyl ether (DGE-DHBP) and 0.202 g (1 mmol) of sebacic acid was placed in a culture medium covered with a polytetrafluoroethylene (PTFE) membrane. Melt in a heating mantle at 180°C and stir gently to mix evenly. Then, 13.9 mg (0.1 mmol) of 1,5,7-triazabicyclo[4.4.0]dec-5-ene (TBD) was added to the mixture, and the mixture was stirred while adding to make the mixture uniform. When the viscosity of the reaction system increases but it has not yet reacted to a solid and can still be drawn, it is taken out and cooled slightly to obtain a prepolymer. Put the prepolymer in two layers of polytetrafluoroethylene (PTFE) films, use tin foil as a gasket to control the thickness of the prepolymer film, and then heat the prepolymer in a tablet press at 6MPa and 180°C Press and cure for 6 hours to obtain a liquid crystal elastomer sample with a target th...

Embodiment 2

[0094] (1) Preparation of liquid crystal elastomer samples

[0095] A mixture of 0.340 g (1 mmol) of 4,4'-dihydroxy-α-methyl-1,2-stilbene diglycidyl ether (DGE-DHMS) and 0.202 g (1 mmol) of sebacic acid was placed in a covered In a petri dish with polytetrafluoroethylene (PTFE) film, melt at 180°C in a heating mantle, and stir gently to make it evenly mixed. Then, 13.9 mg (0.1 mmol) of 1,5,7-triazabicyclo[4.4.0]dec-5-ene (TBD) was added to the mixture, and the mixture was stirred while adding to make the mixture uniform. When the viscosity of the reaction system increases but it has not yet reacted to a solid and can still be drawn, it is taken out and cooled slightly to obtain a prepolymer. Put the prepolymer in two layers of polytetrafluoroethylene (PTFE) films, use tin foil as a gasket to control the thickness of the prepolymer film, and then heat the prepolymer in a tablet press at 6MPa and 180°C Press and cure for 6 hours to obtain a liquid crystal elastomer sample with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com