Leakage-free rolling mill workstation shaft seal device

A workstation, no leakage technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of expensive procurement time of imported spare parts, pollute the site environment, affect the corporate image, etc., achieve foreign exchange saving, good effect, and low cost The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

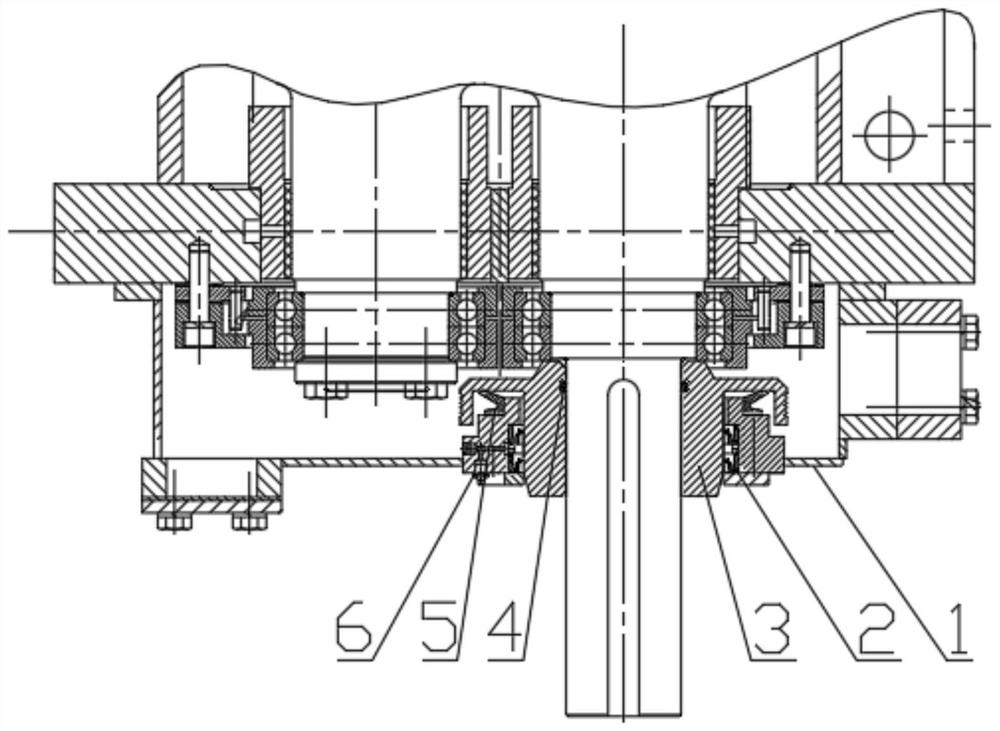

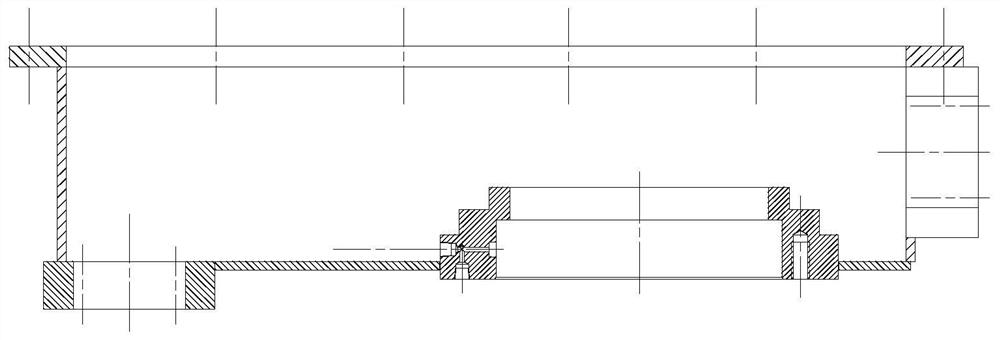

[0027] Such as Figure 1-6 As shown, the embodiment of the present invention discloses a shaft seal device for a non-leakage rolling mill workstation, including an oil pan 1, a skeleton oil seal 2, a shaft sleeve with an oil throwing ring 3, an "O"-shaped seal ring 4, a seal lip 5, and a grease nipple 6.

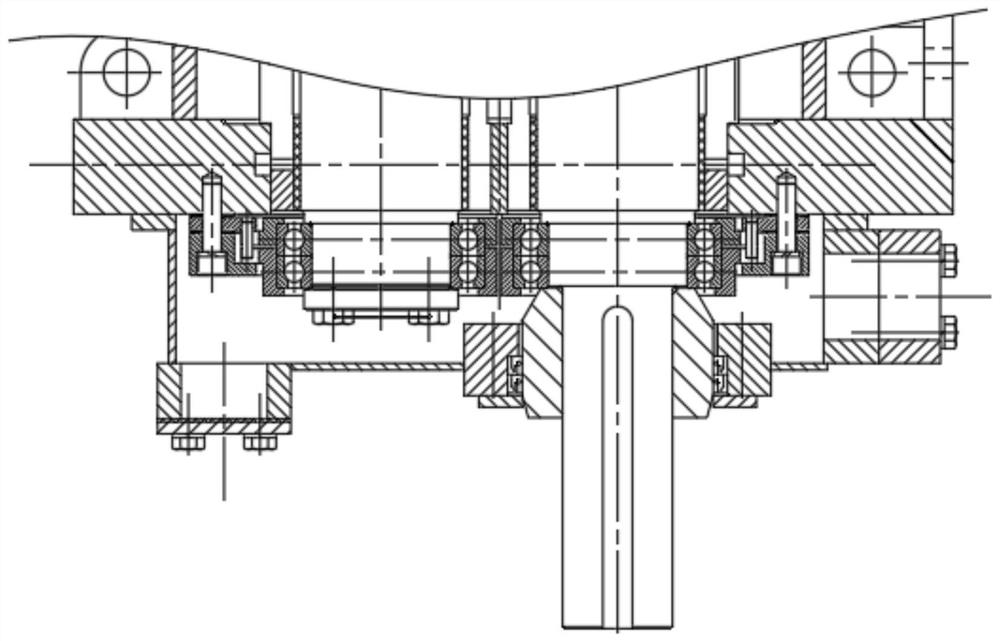

[0028] The main implementation steps are as follows: First, disassemble the flange screws of the oil pan originally designed, remove the old oil pan and the old shaft sleeve, and analyze the main causes of the leakage of the shaft seal device originally designed, such as figure 2 shown. The second is to redesign, improve and optimize the structural size and sealing form of the shaft seal device of the embodiment of the present invention according to the actual site conditions, such as figure 1 shown. The third is to manufacture the oil pan 1 and the shaft sleeve 3 with the oil throwing ring respectively according to the machining technical requirements. The fourth is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com