Flexible pressure sensor, preparation method thereof, and wearable device

A pressure sensor, flexible technology, applied in the sensor field, can solve the problems of increasing the sensor preparation process and manufacturing cost, the sensor response time lag, limiting the sensor detection range, etc., to achieve easy control of the detection range, ensure stability and repeatability, The effect of eliminating the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] In one aspect of the present invention, there is also provided a method for preparing the above-mentioned flexible pressure sensor, comprising the following steps:

[0062] forming an interdigitated electrode with a preset structure on the first flexible substrate by using the graphene composite slurry, and drying to prepare an interdigitated electrode layer;

[0063] Coating a sensing material comprising graphene on a second flexible substrate and drying it to prepare a pressure-sensitive layer; and

[0064] Adhering the interdigital electrode layer and the edge of the pressure-sensitive layer with the adhesive layer having a gap.

[0065] In some embodiments, the specific steps of preparing the interdigital electrode layer include: printing or printing the graphene composite paste on the first flexible substrate to form interdigital electrodes with a preset structure, and drying. The printing may be direct-ink printing, and the printing may be screen printing.

[00...

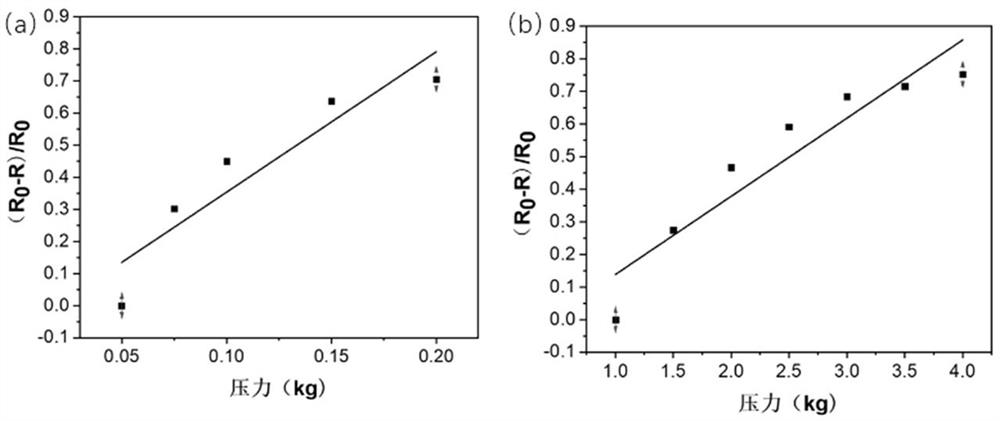

Embodiment 1

[0076] 1) Preparation of interdigitated electrode layer

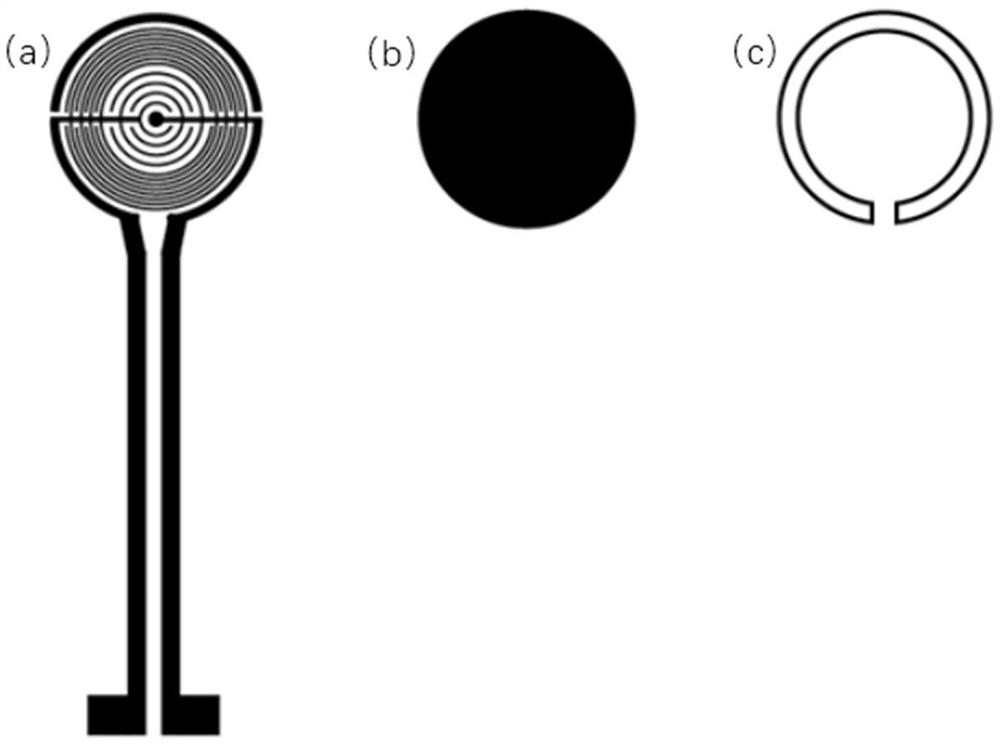

[0077] Put 20g of vinyl acetate resin in 80g of dibasic ester solvent, heat and stir at 60°C until the vinyl acetate resin is completely dissolved to form a vinyl acetate resin solution. Then take 20 g of vinyl chloride resin solution, add 0.8 g of graphene, disperse evenly, vacuum defoam and stir for 10 min to prepare graphene composite slurry. Use the screen printing screen to print the graphene composite paste onto the PET film to form a figure 1 The interdigitated electrode with the preset structure shown in (a), wherein the interdigitated electrode has an interdigitated width of 0.25mm, and within an electrode diameter of 8.5mm, the distance between adjacent interdigitated electrodes is 0.75mm, a total of 2 pairs; When the electrode diameter is between 8.5mm and 13.75mm, the distance between adjacent interdigital electrodes is 0.375mm, and there are 4 pairs in total. Subsequently, the PET film containing the inte...

Embodiment 2

[0087] The preparation method of this embodiment is basically the same as that of Embodiment 1, except that the parameters of the interdigitated electrodes are different. Specific steps are as follows:

[0088] 1) Preparation of interdigitated electrode layer

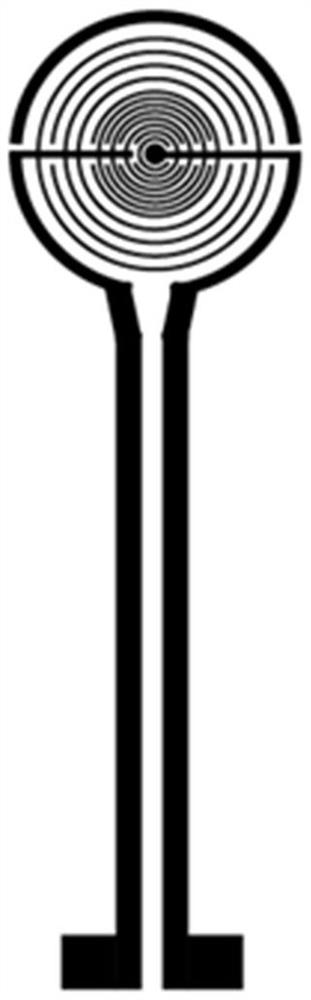

[0089]Put 20g of vinyl acetate resin in 80g of dibasic ester solvent, heat and stir at 60°C until the vinyl acetate resin is completely dissolved to form a vinyl acetate resin solution. Then take 20 g of vinyl chloride resin solution, add 0.8 g of graphene, disperse evenly, vacuum defoam and stir for 10 min to prepare graphene composite slurry. Use the screen printing screen to print the graphene composite paste onto the PET film to form a image 3 The interdigitated electrode with the preset structure shown, wherein the interdigitated electrode has a fork width of 0.25mm, and within an electrode diameter of 8.5mm, the distance between adjacent interdigitated electrodes is 0.375mm, a total of 4 pairs; Between 8.5mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com