Dairy product pasteurization sterilization system and sterilization storage tank thereof

A pasteurization and sterilization system technology, applied in the field of storage tanks, can solve the problems of easy deposition of slag, troublesome cleaning process, and unsteady flow at the sampling point, and achieves the effect of simple operation mode, improved accuracy, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] as attached figure 1 to attach Figure 8 Shown:

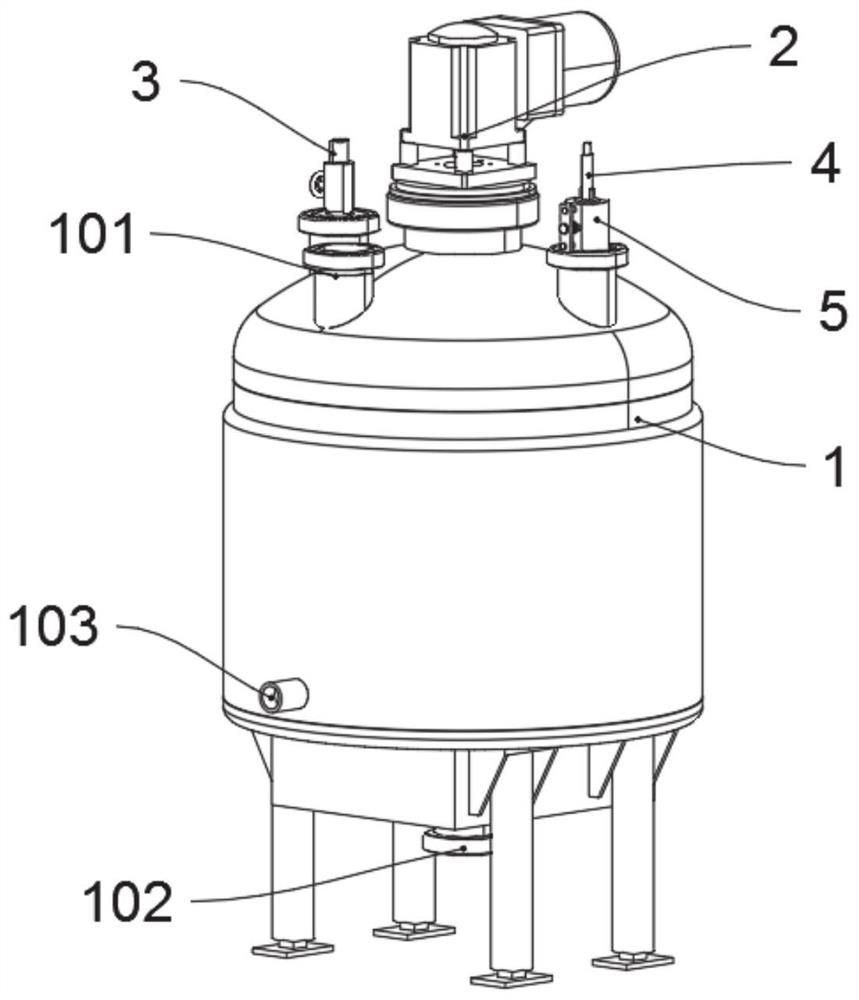

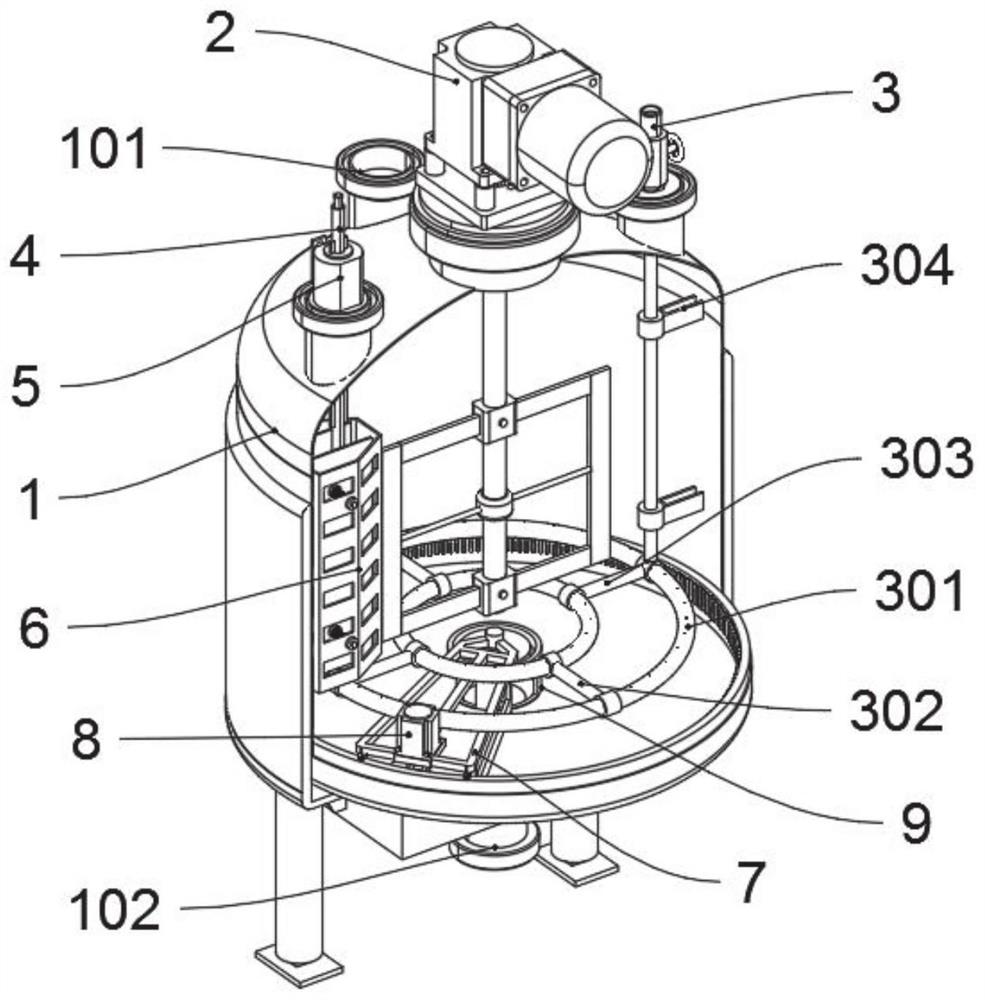

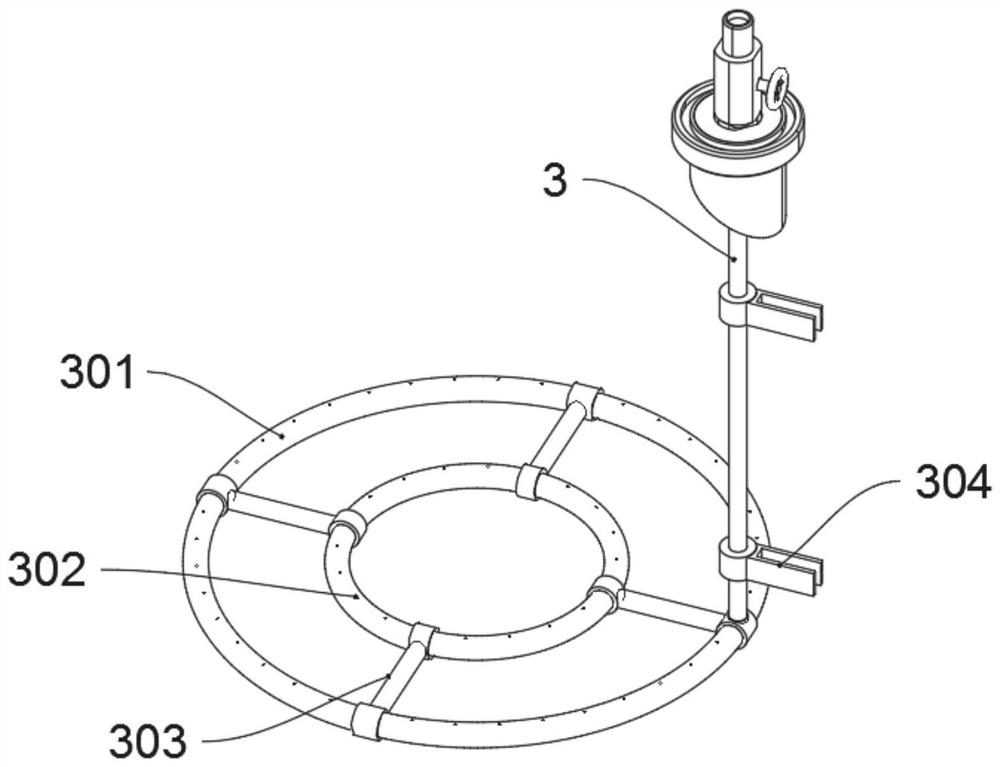

[0044] The present invention provides a pasteurization and sterilization system for dairy products and its sterilized storage tank, including a storage tank body 1; a first motor 2 is provided on the top of the storage tank body 1, and a shaft at the bottom of the first motor 2 runs through the storage tank body 1 top wall, and the shaft is provided with stirring fan blades, and the stirring fan blades are located in the cavity of the storage tank body 1; The top is provided with a feeding port 101, and the feeding port 101 communicates with the interior of the storage tank body 1, the side of the outer peripheral surface of the storage tank body 1 is provided with a cold air inlet 103, and the bottom of the storage tank body 1 is provided with a discharge port 102, and the discharge The port 102 communicates with the receiving pipe 9; one side of the storage tank body 1 is provided with an air duct 3, and the other si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com