Preparation method of polyvinyl alcohol-acrylamide-agarose hydrogel with high mechanical strength

A technology of agarose hydrogel and polyvinyl alcohol, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of poor biocompatibility and poor mechanical properties of hydrogel, and improve biocompatibility , enhance mechanical properties, and promote the effect of chondrocyte proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

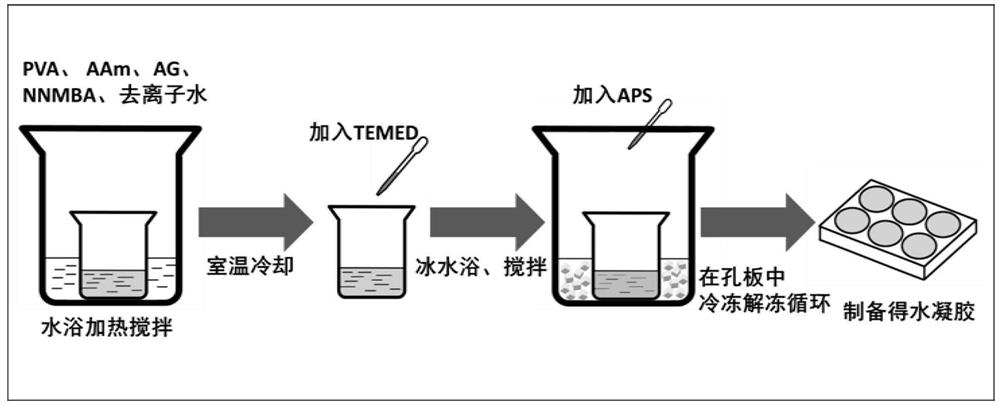

[0022] a) Add 10g of PVA, 10g of AAm, 0.5g of agarose, and 0.1g of N,N'-methylenebisacrylamide into 79mL of deionized water, heat in a constant temperature water bath at 90°C, and stir until the PVA is completely dissolved to obtain a mixed solution A.

[0023] b) Put the mixed solution A at room temperature and keep stirring, and lower the temperature to 20°C for later use. Add 100 μL of tetramethylethylenediamine dropwise to the above mixed solution A, add 3 mL of saturated ammonium persulfate solution in an ice-water bath environment, and stir to obtain mixed solution B.

[0024] c) Pour the mixed solution B into the mold, and perform cyclic freezing and thawing. The freezing temperature is -18°C, the freezing time is 12 hours, and the thawing temperature is 15°C, and the thawing time is 6 hours. The number of cycles is 2 times to obtain polyvinyl alcohol-acrylamide hydrogel.

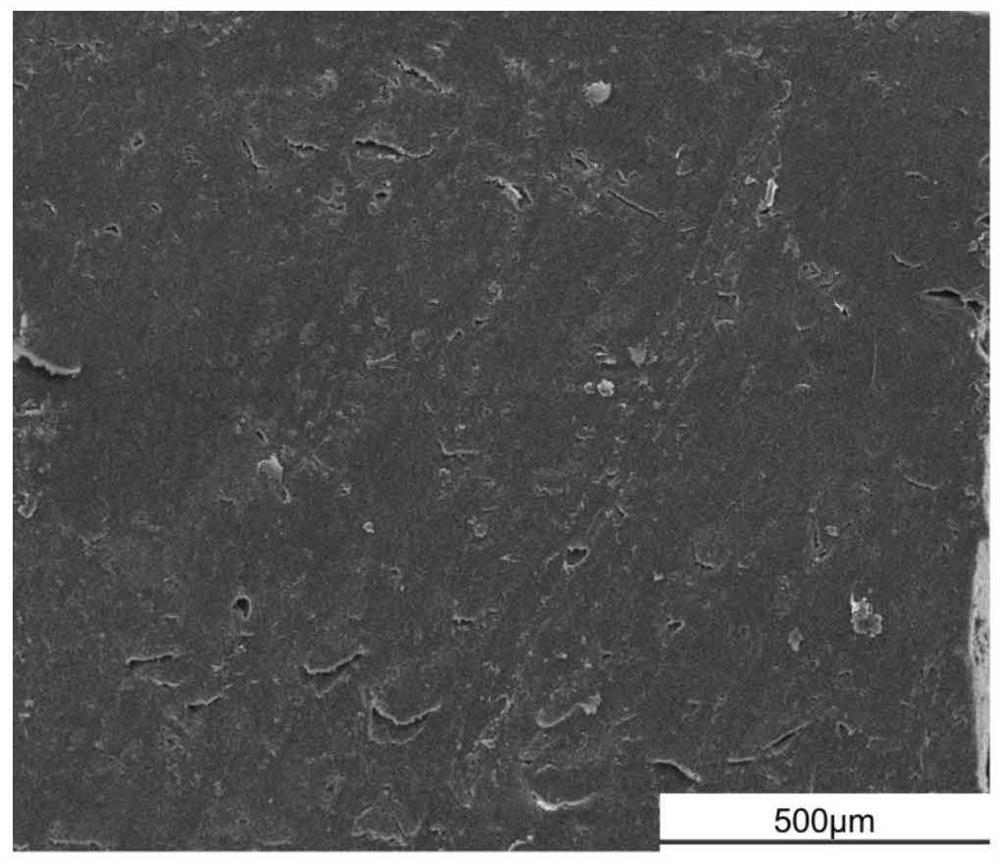

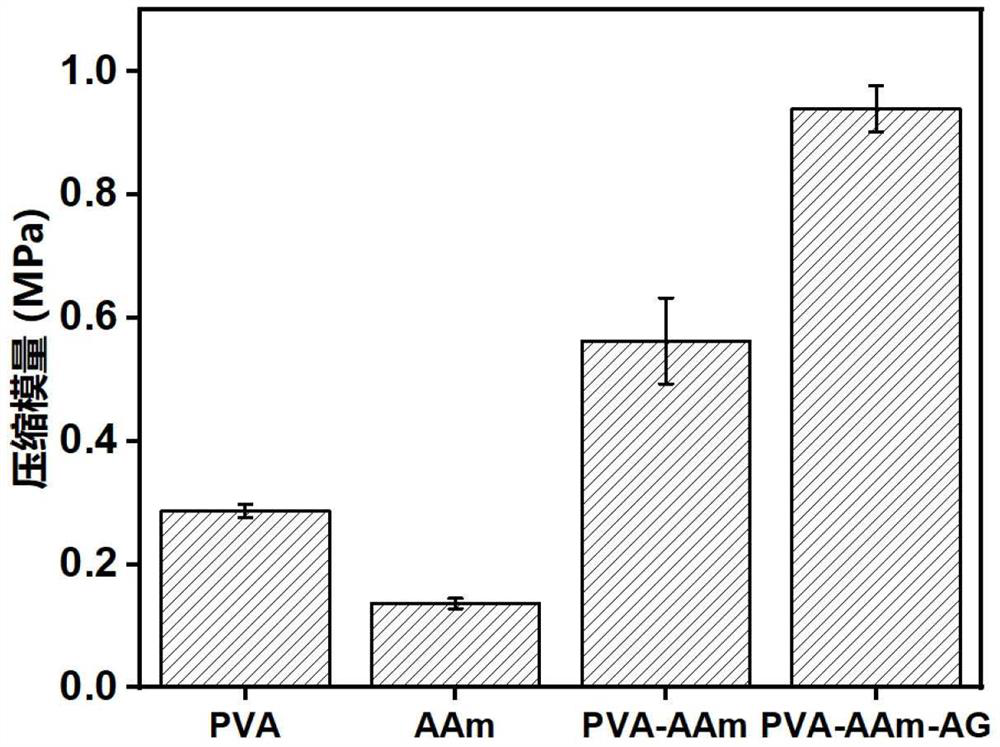

[0025] Based on the PVA-AAm-AG hydrogel prepared by the above steps, the morphology observation,...

Embodiment 2

[0030] a) Add 20g of PVA, 20g of AAm, 5g of agarose, and 0.5g of N,N'-methylenebisacrylamide into 55mL of deionized water, heat in a constant temperature water bath at 99°C, and stir until the PVA is completely dissolved to obtain a mixed solution A.

[0031] b) Place the mixed solution A at room temperature and continue to stir, and lower the temperature to 50°C for later use. Add 200 μL of tetramethylethylenediamine dropwise to the above mixed solution A, add 6 mL of saturated ammonium persulfate solution in an ice-water bath environment, and stir to obtain mixed solution B.

[0032] c) Pour the mixed liquid B into the mold, and perform cyclic freezing and thawing. The freezing temperature is -25°C, the freezing time is 20h, and the thawing temperature is 25°C, and the thawing time is 12h. The number of cycles is 4 times to obtain polyvinyl alcohol-acrylamide hydrogel.

[0033] Based on the PVA-AAm-AG hydrogel prepared by the above steps, the morphology observation, mechani...

Embodiment 3

[0035] a) Add 15g of PVA, 15g of AAm, 2.5g of agarose, and 0.25g of N,N'-methylenebisacrylamide into 67mL of deionized water, heat in a constant temperature water bath at 95°C, and stir until the PVA is completely dissolved to obtain a mixed solution A.

[0036] b) Place the mixed solution A at room temperature and continue to stir until the temperature drops to 35°C for later use. Add 450 μL of tetramethylethylenediamine dropwise to the above mixed solution A, add 4.5 mL of saturated ammonium persulfate solution in an ice-water bath environment, and stir to obtain mixed solution B.

[0037] c) Pour the mixed solution B into the mold, and perform cyclic freezing and thawing. The freezing temperature is -22°C, the freezing time is 16 hours, and the thawing temperature is 20°C, and the thawing time is 9 hours. The number of cycles is 3 times to obtain polyvinyl alcohol-acrylamide hydrogel.

[0038] Based on the PVA-AAm-AG hydrogel prepared by the above steps, the morphology obs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com