High-rigidity high-modulus antistatic PC composition and preparation method thereof

A high-modulus, anti-static technology, applied in the field of polycarbonate, can solve the problems of stress cracking, high notch impact sensitivity, general chemical resistance of polycarbonate, etc., to reduce the degree of phase separation, improve various properties, The effect of improving the notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

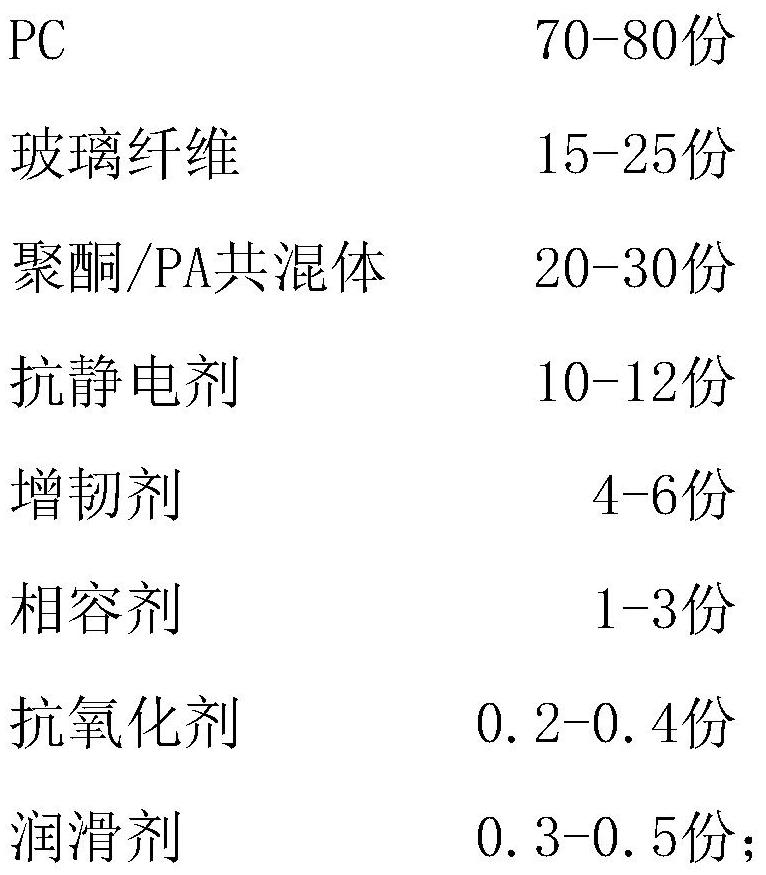

[0025] A high-rigidity high-modulus antistatic PC composition, comprising the following raw materials in parts by weight:

[0026]

[0027] The preparation method of the polyketone / PA blend is as follows: 12.5 parts by weight of polyketone, 12.5 parts by weight of PA66 and 175 parts by weight of solvent are added to the reaction kettle, and the temperature is raised to 165 ° C under a high-pressure inert gas atmosphere. Insulate for 2 hours, then cool down to room temperature at a cooling rate of 2°C / min under stirring conditions, and finally perform solid-liquid separation, drying, and sieving to obtain the polyketone / PA blend.

[0028] Wherein, the solvent is composed of ethanol and n-butanol in a weight ratio of 85:15.

[0029] Wherein, the polyketone is POK M330A.

[0030] Wherein, the glass fiber is an alkali-free glass fiber with a diameter of 14 μm and a model number of EDR14-2000-988A.

[0031] Wherein, the antistatic agent is conductive carbon black.

[0032] Wh...

Embodiment 2

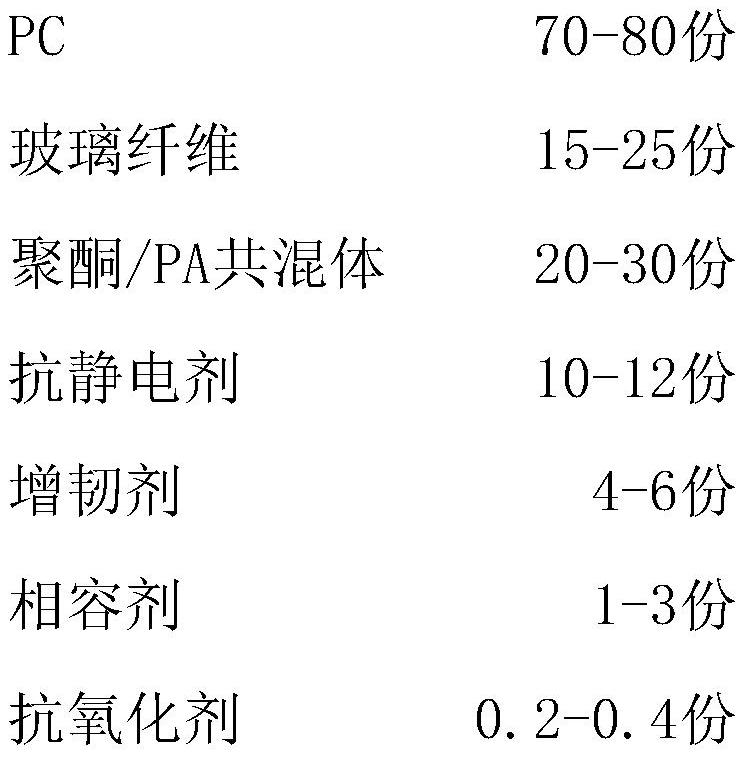

[0038] A high-rigidity high-modulus antistatic PC composition, comprising the following raw materials in parts by weight:

[0039]

[0040] The preparation method of the polyketone / PA blend is as follows: 15 parts by weight of polyketone, 15 parts by weight of PA66 and 200 parts by weight of solvent are added to the reaction kettle, and the temperature is raised to 170 ° C under a high-pressure inert gas atmosphere. Insulate for 1 hour, then cool down to room temperature at a cooling rate of 3°C / min under stirring conditions, and finally perform solid-liquid separation, drying, and sieving to obtain the polyketone / PA blend.

[0041] Wherein, the solvent is composed of ethanol and n-butanol in a weight ratio of 90:10.

[0042] Wherein, the polyketone is POK M330A.

[0043] Wherein, the glass fiber is an alkali-free glass fiber with a diameter of 20 μm.

[0044] Wherein, the antistatic agent is carbon nanotubes.

[0045] Wherein, the toughening agent is composed of S-2001 ...

Embodiment 3

[0051] A high-rigidity high-modulus antistatic PC composition, comprising the following raw materials in parts by weight:

[0052]

[0053] The preparation method of the polyketone / PA blend is as follows: 10 parts by weight of polyketone, 10 parts by weight of PA66 and 150 parts by weight of solvent are added to the reaction kettle, and the temperature is raised to 160 ° C under a high-pressure inert gas atmosphere. Insulate for 3 hours, then cool down to room temperature at a cooling rate of 1° C. / min under stirring conditions, and finally perform solid-liquid separation, drying, and sieving to obtain the polyketone / PA blend.

[0054] Wherein, the solvent is composed of ethanol and n-butanol in a weight ratio of 80:20.

[0055] Wherein, the polyketone is POK M330A.

[0056] Wherein, the glass fiber is an alkali-free glass fiber with a diameter of 10 μm.

[0057] Wherein, the antistatic agent is graphene.

[0058] Wherein, the toughening agent is composed of S-2001 and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com