Operation control system of static pressure air suspension centrifugal refrigeration compressors

A technology of refrigeration compressors and centrifugal compressors, applied in engine control, pump control, mechanical equipment, etc., can solve problems such as increased pollution risk of ultra-high-speed oil system, and achieve the effect of eliminating human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

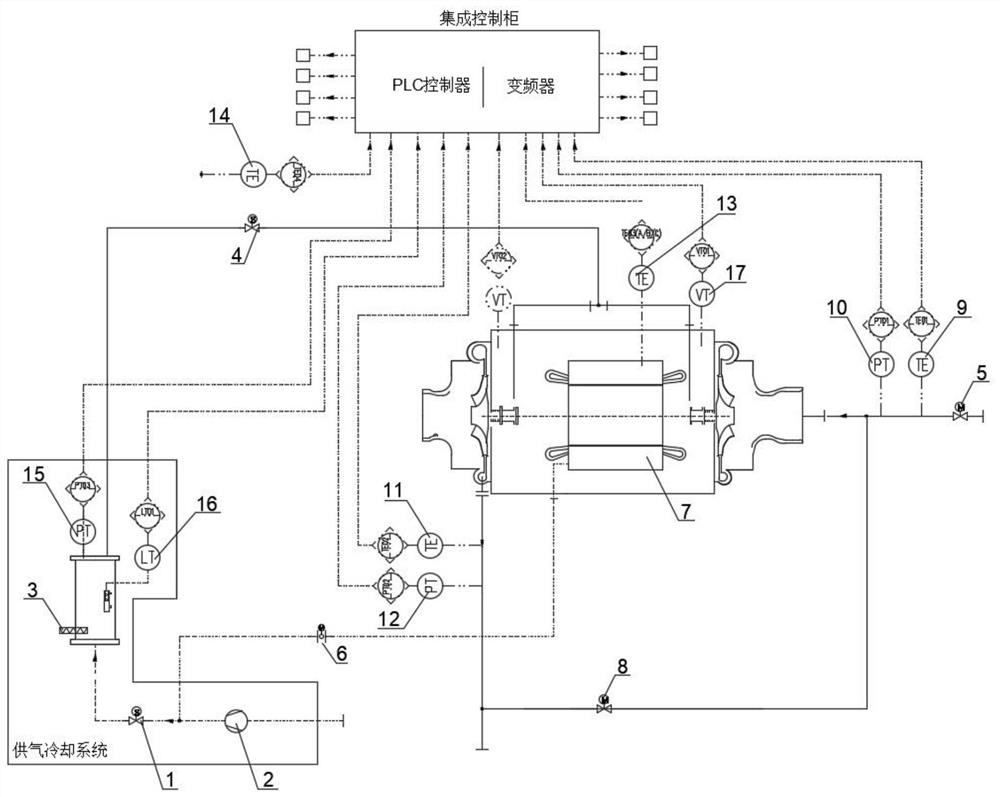

Method used

Image

Examples

Embodiment 1

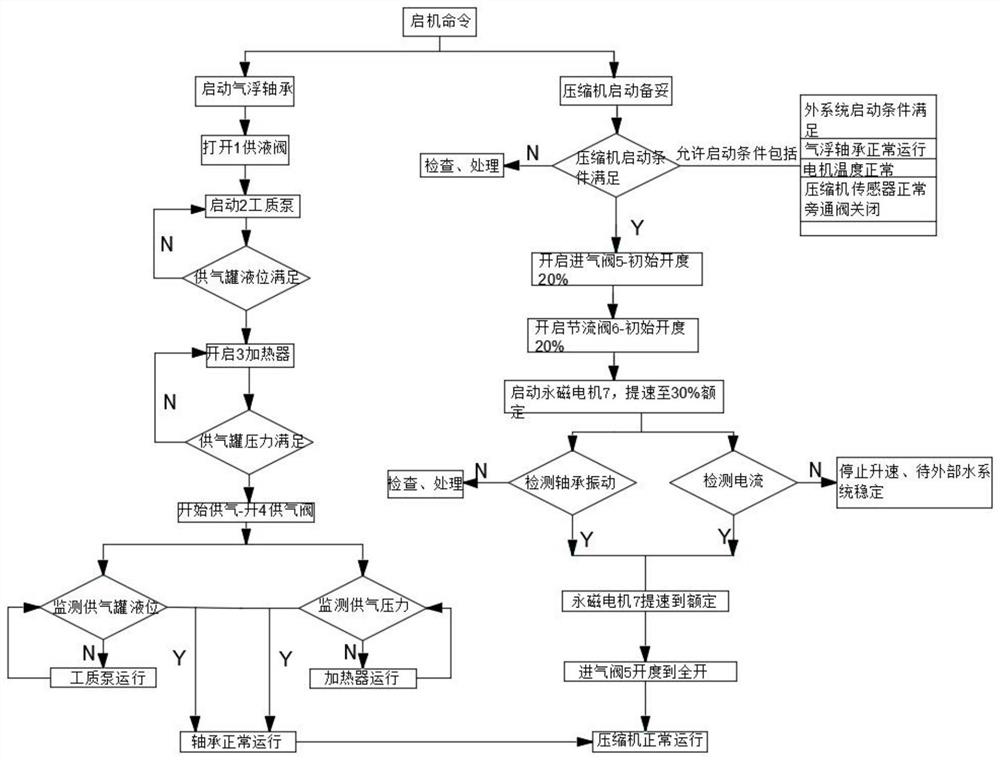

[0049] like figure 2 As shown, the startup process includes:

[0050] Step S1: According to the start-up command, first start the air bearing, open the liquid supply valve 1, set the liquid supply valve 1 to open for 5 seconds and then start the working medium pump 2, judge that the liquid level of the air supply tank 16 reaches the set value LTset1, and then open Electric heater 3;

[0051] Step S2: After judging that the pressure 15 of the air supply tank reaches the set value Pset1, open the air supply valve 4. At this time, as the air supplied to the bearing enters the compressor, the air bearing starts to enter the air floating state. In order to keep the air bearing working normally, It is necessary to monitor the liquid level 16 of the gas supply tank and the pressure 15 of the gas supply tank in real time. According to the difference between the liquid level 16 of the gas supply tank and the set value LTset01 as the input of the PID algorithm, the operating frequency...

Embodiment 2

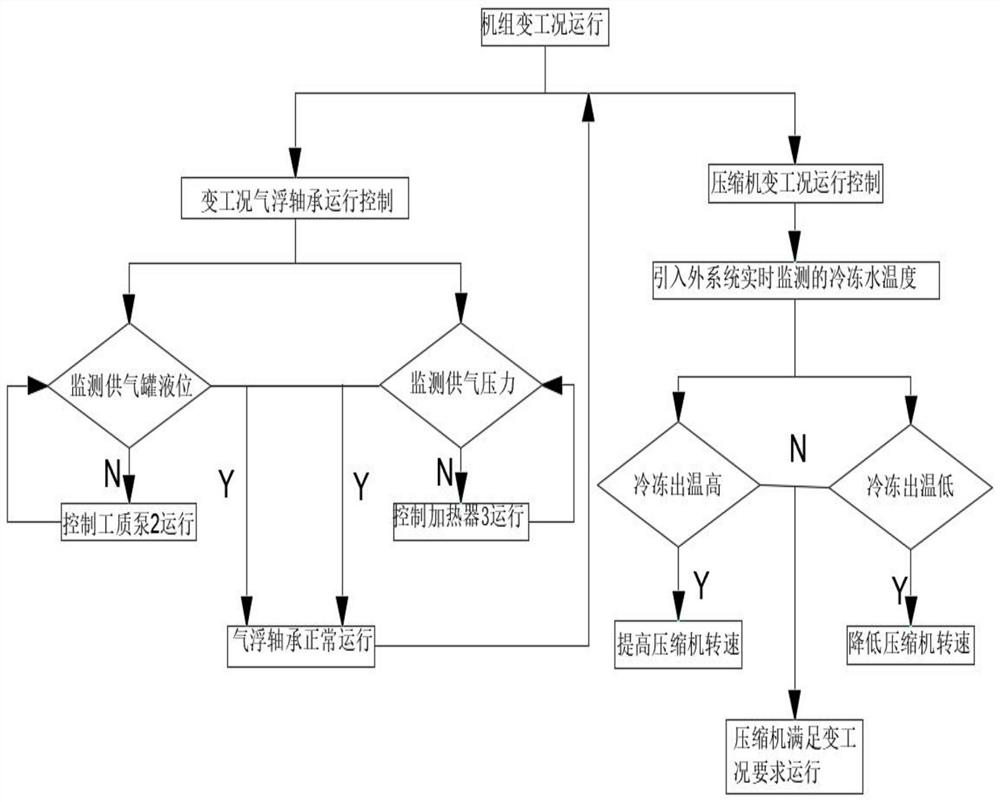

[0059] like image 3 As shown, the variable working condition of the compressor mainly refers to the need to adjust the operating speed of the compressor as the heat load of the external system changes, so as to ensure the water supply temperature required by the external system, and at the same time make the compressor run in a stable, safe and efficient state. In addition, this process can realize fully adaptive and intelligent control and operation without human intervention.

[0060] The operation process of the compressor unit under variable working conditions includes:

[0061] The signal for the compressor to automatically sense changes in working conditions comes from the chilled water temperature 14 of the external system, and the value of the chilled water temperature 14 is marked as TE04. By judging whether the chilled water temperature 14 is within the set temperature range, it is determined whether the compressor speeds up or not. Decrease the speed. At this time...

Embodiment 3

[0066] like Figure 4 As shown, the security system of the compressor includes a compressor component status protection module, an anti-surge protection module, a motor operation protection module and a compressor operation protection module.

[0067] The compressor component status protection module monitors the status of all sensors, valves, electric heaters 3, pumps, permanent magnet motors 7 and other components, and feeds back to the PLC whether the status of each component is normal or faulty, as a basic protection; Component failure signal, that is, through PLC alarm and protection shutdown, reminding to troubleshoot;

[0068] The compressor anti-surge protection module judges whether it is at the risk of surge by comparing the ratio of the compressor discharge pressure 12 to the compressor intake pressure 10 with the value of the compressor surge risk line; that is, read (PT02 / PT01) is compared with the value of the surge risk line, if it exceeds the allowable limit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com