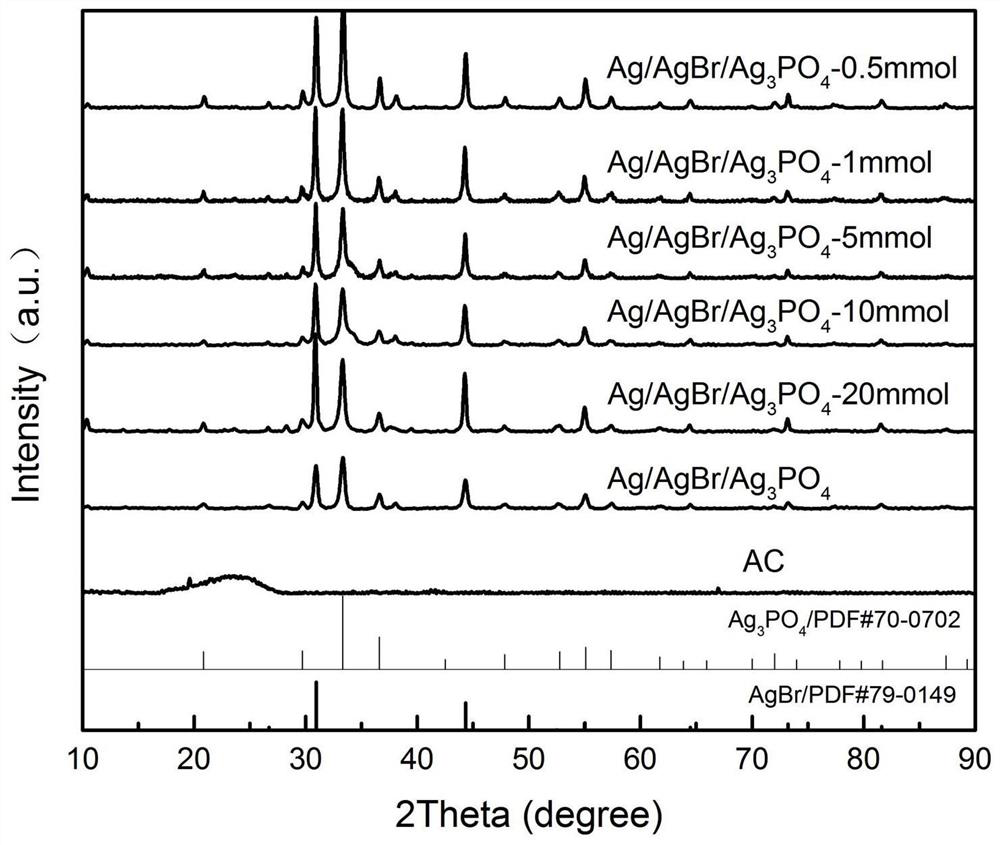

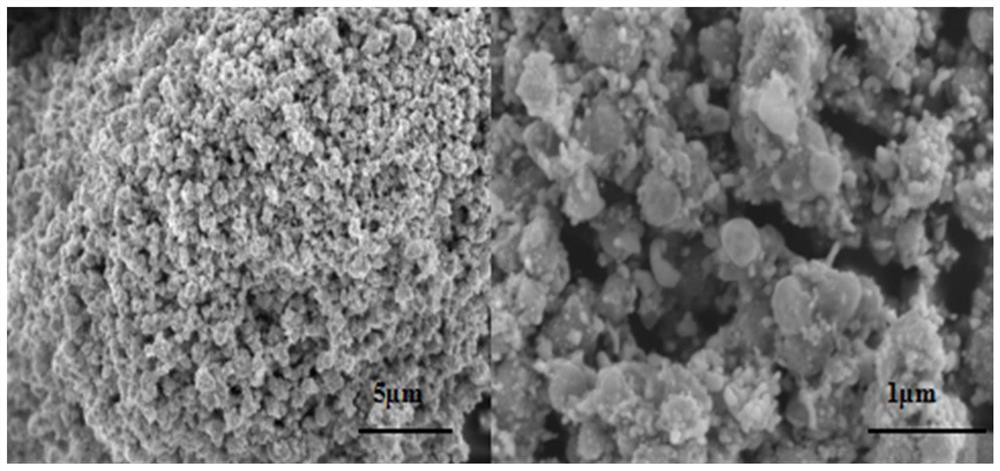

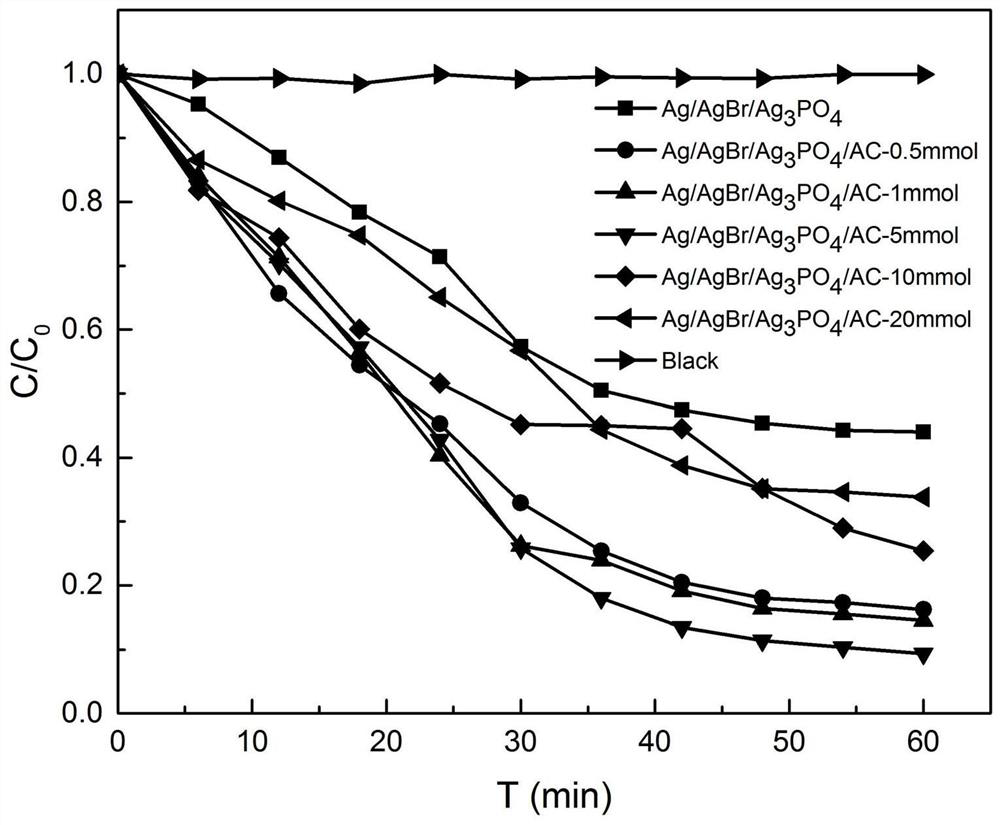

Preparation method of Ag/AgBr/Ag3PO4/AC composite photocatalyst with activated carbon as carrier

A composite photo-catalyst technology, applied in the field of photocatalysis, can solve the problems that are difficult to apply, and achieve the effect of promoting separation, strong specific surface area, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) AgBr / Ag 3 PO 4 Preparation of / AC

[0033] Add 0.0021g of activated carbon into 10mL of deionized water, ultrasonically oscillate for 10min, and stir magnetically for 10min to disperse the activated carbon evenly to obtain a suspension, then add 10mL of AgNO 3 Solution (0.14mol / L) was added dropwise to the above suspension, and stirred in the dark for 30min; continue to add 10mL Na 3 C 6 h 5 o 7 2H 2 O solution (0.14mol / L) was added dropwise to it, and after the dropwise addition, continued to stir in the dark for 30min; then, under magnetic stirring, 10mL of KBr solution (0.14mol / L) was added dropwise to it, and then continued to stir in the dark for 10min ; Finally Na 2 HPO 4 The solution (0.035mol / L) was added dropwise to the above mixture, and after the dropwise addition, the stirring was continued for 30 min in the dark to ensure that there was enough time for all the reactions to proceed completely. The product was collected by centrifugation, washed ...

Embodiment 2

[0038] (1) AgBr / Ag 3 PO 4 Preparation of / AC

[0039] Add 0.0042g of activated carbon into 10mL of deionized water, ultrasonically oscillate for 10min, and magnetically stir for 10min to disperse the activated carbon evenly to obtain a suspension, then add 10mL of AgNO 3 Solution (0.14mol / L) was added dropwise to the above suspension, and stirred in the dark for 30min; continue to add 10mL Na 3 C 6 h 5 o 7 2H 2 O solution (0.14mol / L) was added dropwise to it, and after the dropwise addition, continued to stir in the dark for 30min; then, under magnetic stirring, 10mL of KBr solution (0.14mol / L) was added dropwise to it, and then continued to stir in the dark for 10min ; Finally Na 2 HPO 4 The solution (0.035mol / L) was added dropwise to the above mixture, and after the dropwise addition, the stirring was continued for 30 min in the dark to ensure that there was enough time for all the reactions to proceed completely. The product was collected by centrifugation, washed ...

Embodiment 3

[0044] (1) AgBr / Ag 3 PO 4 Preparation of / AC

[0045] Add 0.0084g of activated carbon into 10mL of deionized water, ultrasonically oscillate for 10min, and magnetically stir for 10min to disperse the activated carbon evenly to obtain a suspension, then add 10mL of AgNO 3 Solution (0.14mol / L) was added dropwise to the above suspension, and stirred in the dark for 30min; continue to add 10mL Na 3 C 6 h 5 o 7 2H 2 O solution (0.14mol / L) was added dropwise to it, and after the dropwise addition, continued to stir in the dark for 30min; then, under magnetic stirring, 10mL of KBr solution (0.14mol / L) was added dropwise to it, and then continued to stir in the dark for 10min ; Finally Na 2 HPO 4 The solution (0.035mol / L) was added dropwise to the above mixture, and after the dropwise addition, the stirring was continued for 30 min in the dark to ensure that there was enough time for all the reactions to proceed completely. The product was collected by centrifugation, washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com