Method and device for removing carbon deposit in quench cooler of hexafluoropropylene reaction equipment

A technology of hexafluoropropylene and reaction equipment, which is applied in the field of removing carbon deposits in the quencher of the hexafluoropropylene reaction equipment, can solve the problems of reducing the gas phase flow rate of the reaction equipment, increasing the reaction residence time, and the high toxicity of octafluoroisobutylene. Save manpower and material resources, reduce operation frequency and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

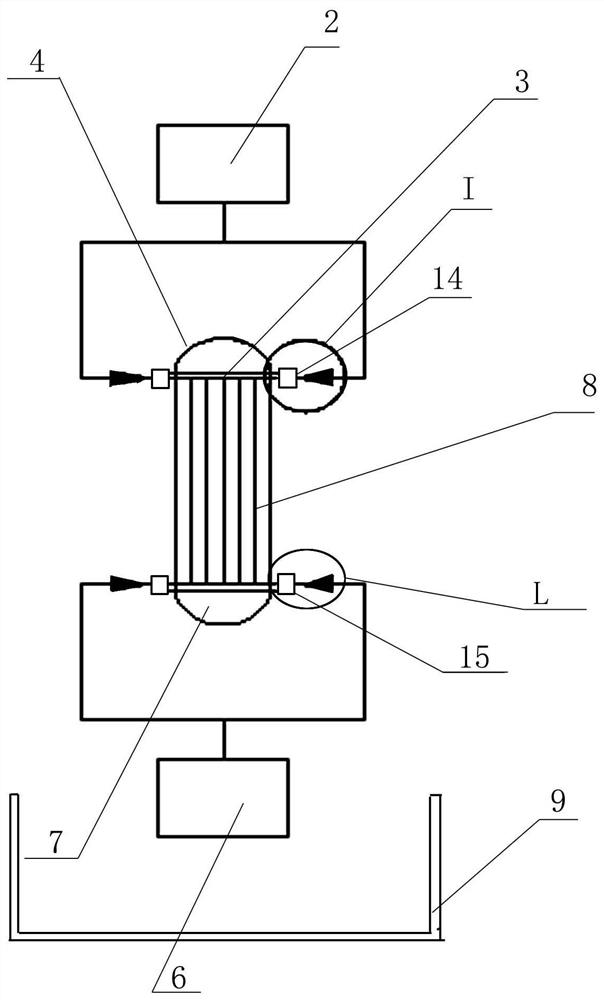

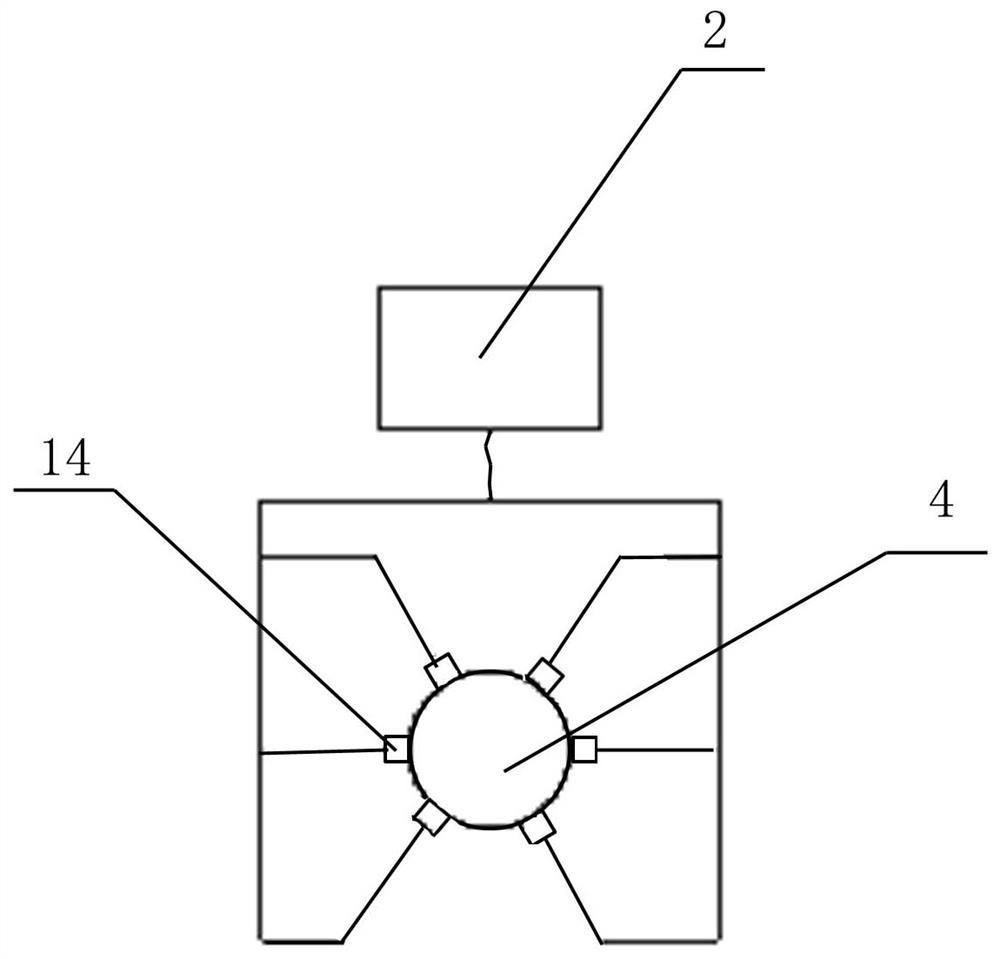

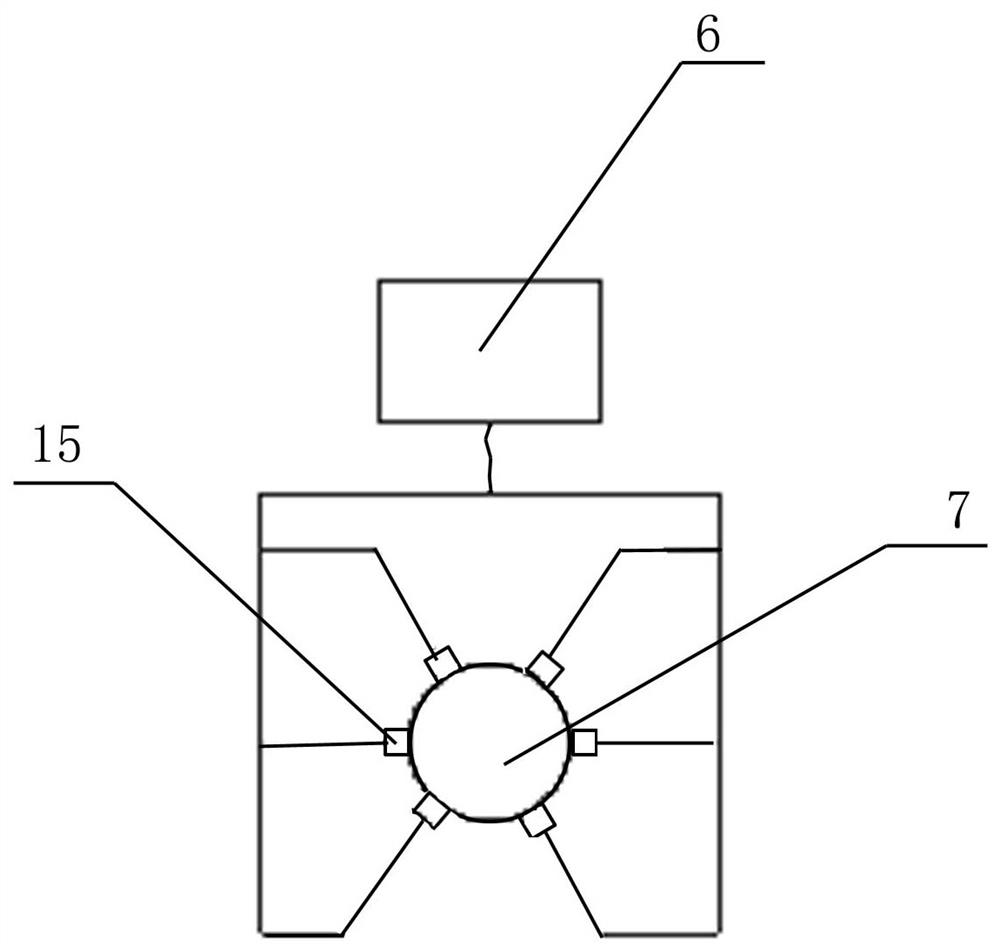

[0014] exist figure 1 Among them, the present invention discloses a device for removing carbon deposits in the quencher of hexafluoropropylene reaction equipment, which includes an upper vibration assembly and a lower vibration assembly. The upper vibration assembly mainly includes several upper ultrasonic vibration devices 14, several The upper control end 1 of the upper ultrasonic vibrating device 14 is all connected with the upper controller 2, and several upper ultrasonic vibrating devices 14 are evenly installed on the top cover 4 outer surface of the quencher 3, and some upper ultrasonic vibrating devices 14 connect the top cover of the quencher 3 4 surrounded by the figure 2 and Figure 4 Among them, the upper vibrating assembly of the present embodiment mainly includes six upper ultrasonic vibrating devices 14, and the six upper ultrasonic vibrating devices 14 are uniformly installed on the outer surface of the quench cooler 3 top cover 4, and each upper ultrasonic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com