Nitrogen oxide nanosheet, preparation method thereof, photocatalyst and photocatalytic antibacterial agent

A photocatalytic antibacterial agent, nitrogen oxide technology, applied in botanical equipment and methods, physical/chemical process catalysts, nitrogen compounds, etc., can solve problems such as affecting activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

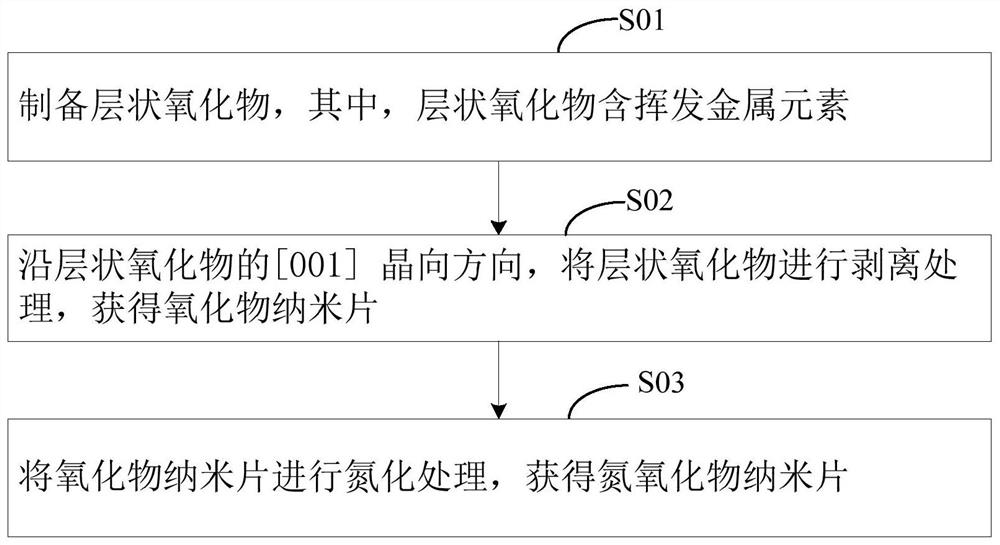

[0025] The embodiment of the present application provides a preparation method of nitrogen oxide nanosheets. The preparation method specifically includes the following steps:

[0026] S01: preparing a layered oxide, wherein the layered oxide contains volatile metal elements;

[0027] S02: Exfoliate the layered oxide along the [001] crystal phase direction of the layered oxide to obtain oxide nanosheets;

[0028] S03: Nitriding the oxide nanosheets to obtain nitrogen oxide nanosheets.

[0029] The preparation method of nitrogen oxide nanosheets provided in the examples of the present application is to prepare layered oxides containing volatile metal elements. The volatile metal elements can be volatilized from the surface of layered oxides during the nitriding process, and the remaining elements are heated in ammonia gas. Under the atmosphere, it quickly transforms into nitrogen oxide nanosheets along the [010] crystal phase direction, and retains the original sheet shape, whi...

Embodiment 1

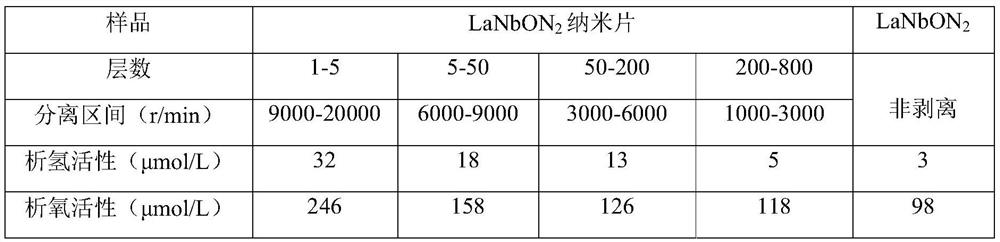

[0049] A preparation method of nitrogen oxide nanosheets (the number of layers is 1-5 layers), comprising the following steps:

[0050] S01:

[0051] A narrow oxynitride nanosheet (the number of layers is 1-5 layers of LaNbON 2 Nano sheet) preparation method, comprises the following steps:

[0052] S01: Preparation of layered oxide LaKNaNbO by NaOH / KOH molten salt method 5 Nitriding precursors.

[0053] Take 5mmol La 2 o 3 and 5 mmol Nb 2 o 5 Grind thoroughly in a mortar to obtain La 2 o 3 , Nb 2 o 5 mixture; then La 2 o 3 , Nb 2 o 5 The mixture was transferred to an alumina crucible and 10g KOH and 5g NaOH were added, then the alumina crucible was placed in a muffle furnace, heated to 873K at a heating rate of 10K / min, kept at 873K for 3 hours and then cooled to 773K, Then it was incubated at 773K for 15 hours and then naturally cooled to room temperature to obtain LaKNaNbO 5 Reaction product; finally, the reaction product was washed 3-5 times with ultrapure w...

Embodiment 2

[0061] A narrow oxynitride nanosheet (the number of layers is 5-50 layers of LaNbON2 Nano sheet) preparation method, comprises the following steps:

[0062] S01: Preparation of layered oxide LaKNaNbO by NaOH / KOH molten salt method 5 Nitriding precursors.

[0063] Take 5mmol La 2 o 3 and 5 mmol Nb 2 o 5 Grind thoroughly in a mortar to obtain La 2 o 3 , Nb 2 o 5 mixture; then La 2 o 3 , Nb 2 o 5 The mixture was transferred to an alumina crucible and 10g KOH and 5g NaOH were added, then the alumina crucible was placed in a muffle furnace, heated to 873K at a heating rate of 10K / min, kept at 873K for 3 hours and then cooled to 773K, Then it was incubated at 773K for 15 hours and then naturally cooled to room temperature to obtain LaKNaNbO 5 Reaction product; Finally, the reaction product was washed 3-5 times with ultrapure water at room temperature and centrifuged to remove residual NaOH and KOH, followed by vacuum drying to obtain the layered oxide LaKNaNbO 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com