Cutting method and cutting system for improving cutting quality of tempered glass

A technology for strengthening glass and cutting system, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unstable processing quality, cumbersome processing process, narrow process window, etc., to improve cutting quality and consistency, The effect of improving the cutting quality and increasing the process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

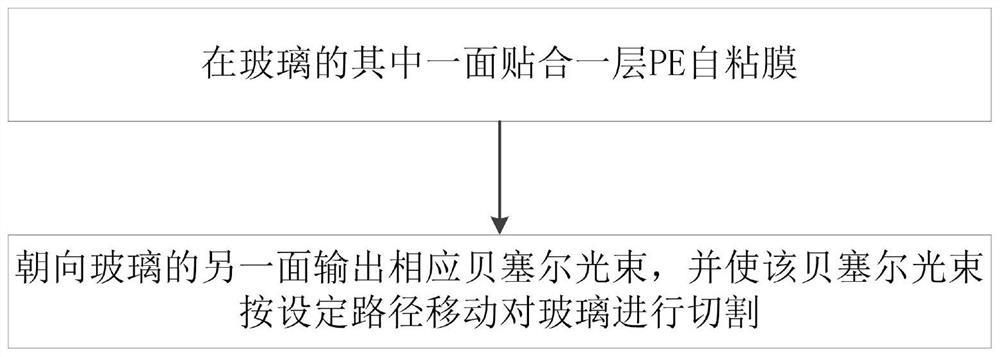

[0031] In this example, if Figure 1 to Figure 6 As shown, the present embodiment provides a cutting method for improving the cutting quality of strengthened glass, which includes: attaching a layer of PE self-adhesive film 5 on one side of the glass 4; outputting a corresponding Bessel beam towards the other side of the glass 4, And make the Bessel beam move according to the set path to cut the glass 4 .

[0032] In this embodiment, this embodiment can solve the chaotic collapse of the glass 4 during cutting by attaching a layer of PE self-adhesive film 5 to one side of the glass 4, and cutting the side of the glass 4 that is not pasted with the PE self-adhesive film 5. Open the problem, improve the cutting quality, can also increase the process window, improve the stability, through the bonding of the PE self-adhesive film 5, the glass 4 and the PE self-adhesive film 5 can be closely bonded, so that the sample can be fixed after the cutting is completed. Avoid random flying...

Embodiment 2

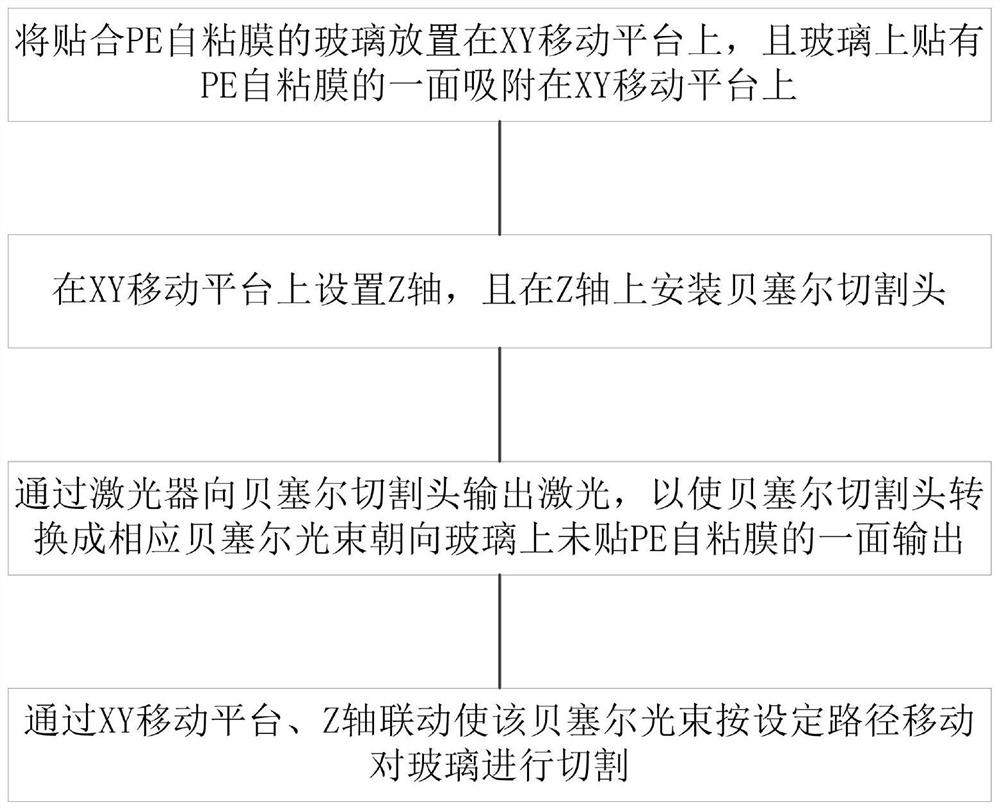

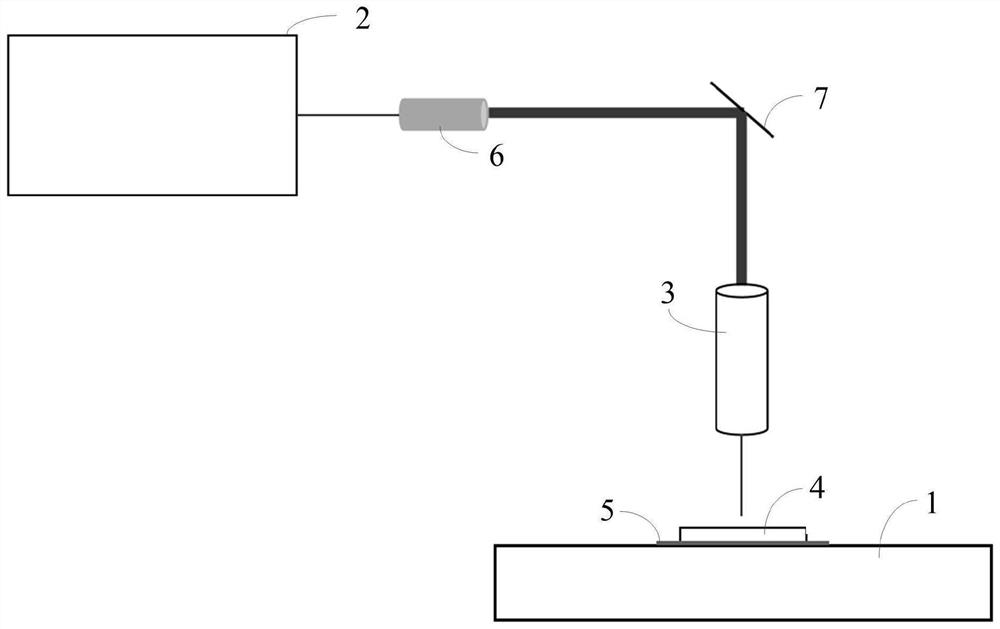

[0043] On the basis of Embodiment 1, this embodiment provides a cutting system for improving the cutting quality of strengthened glass, which includes: XY moving platform 1, Z axis, laser 2 and Bessel cutting head 3; A layer of PE self-adhesive film 5 is pasted on one side; the Z axis is located above the XY mobile platform 1, and the Bessel cutting head 3 is installed on the Z axis; the XY mobile platform 1 is attached with a PE self-adhesive film 4 One side of the mucous membrane 5; the laser 2 outputs laser light to the Bessel cutting head 3, so that the Bessel cutting head 3 is converted into a corresponding Bessel beam and output towards the side of the glass 4 that is not pasted with the PE self-mucosal membrane 5; The XY moving platform 1 and the Z axis are linked so that the Bessel beam moves along a set path to cut the glass 4 .

[0044] In this embodiment, the cutting system further includes: a film sticking device; the film sticking device is suitable for sticking a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com