Self-repairing cement-based composite material as well as preparation method and application thereof

A composite material and self-repairing technology, which is applied in the field of building materials, can solve problems such as poor repairing effect of cracks inside concrete, difficulty in ensuring long-term activity of microorganisms, and complicated manufacturing process of microcapsule materials, so as to ensure long-term effectiveness and self-repairing effect The effect of improvement, efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

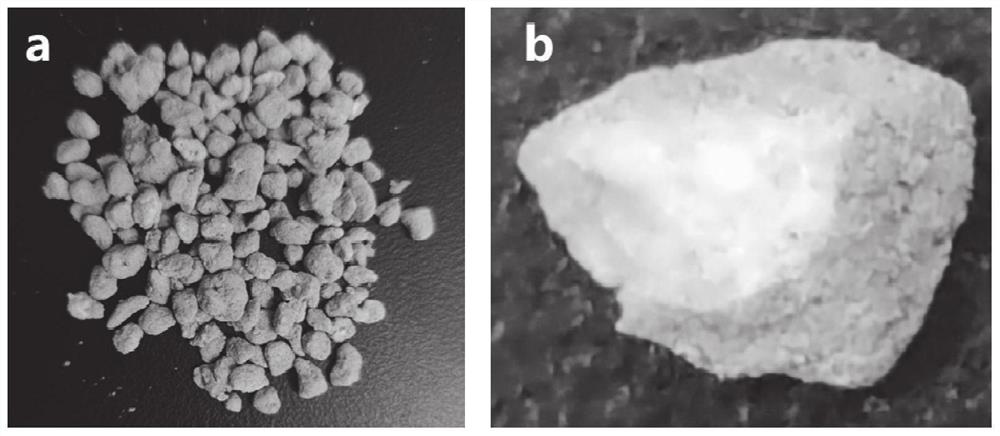

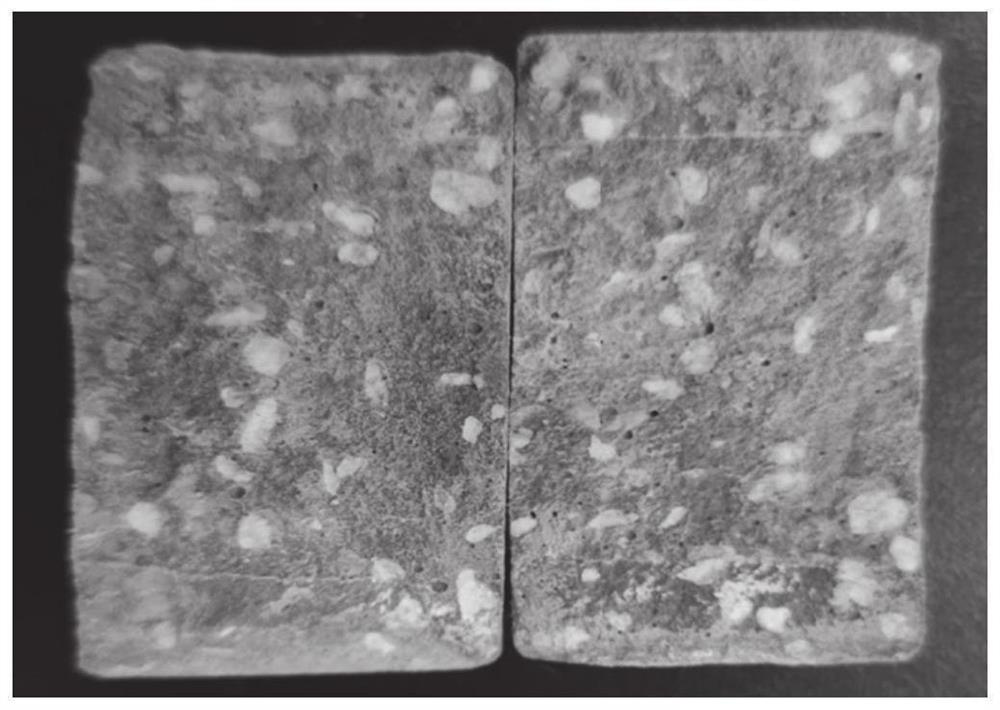

[0065] A method for preparing a self-repairing cement-based composite material, comprising the following contents:

[0066] Step 1: Prepare self-healing particles according to the preparation method in Step 1 of Example 1.

[0067] Step 2: Weighing raw materials in parts by mass, including 97.1 parts of cement matrix material, 8 parts of self-repairing particles, and 2 parts of calcium source substrate (calcium chloride).

[0068] The cement matrix material comprises the following components by weight: 30 parts of cement, 20 parts of fly ash, 25 parts of quartz sand, 1 part of PVA fiber, 1 part of water reducer, 0.1 part of thickener, and 20 parts of water.

[0069] Step 3: Put the above-mentioned weighed raw materials into the mixer, and stir them thoroughly according to the order of the preparation methods of the composite materials.

[0070] Step 4: shape the stirred material, and store it in an environment of 95% humidity and 20°C for up to 7 days.

[0071] Step 5: The p...

Embodiment 2

[0075] A method for preparing a self-repairing cement-based composite material, comprising the following contents:

[0076] Step 1: Prepare self-healing particles according to the preparation method in Step 1 of Example 1.

[0077] Step 2: Weighing raw materials in parts by mass, including 97.1 parts of cement matrix material, 12 parts of self-repairing particles, and 3 parts of calcium source substrate (calcium chloride).

[0078] The cement matrix material comprises the following components by weight: 30 parts of cement, 20 parts of fly ash, 25 parts of quartz sand, 1 part of PVA fiber, 1 part of water reducer, 0.1 part of thickener, and 20 parts of water.

[0079] Step 3: Put the above-mentioned weighed raw materials into the mixer, and stir them thoroughly according to the order of the preparation methods of the composite materials.

[0080] Step 4: shape the stirred material, and store it in an environment of 95% humidity and 20°C for up to 7 days.

[0081] Step 5: The ...

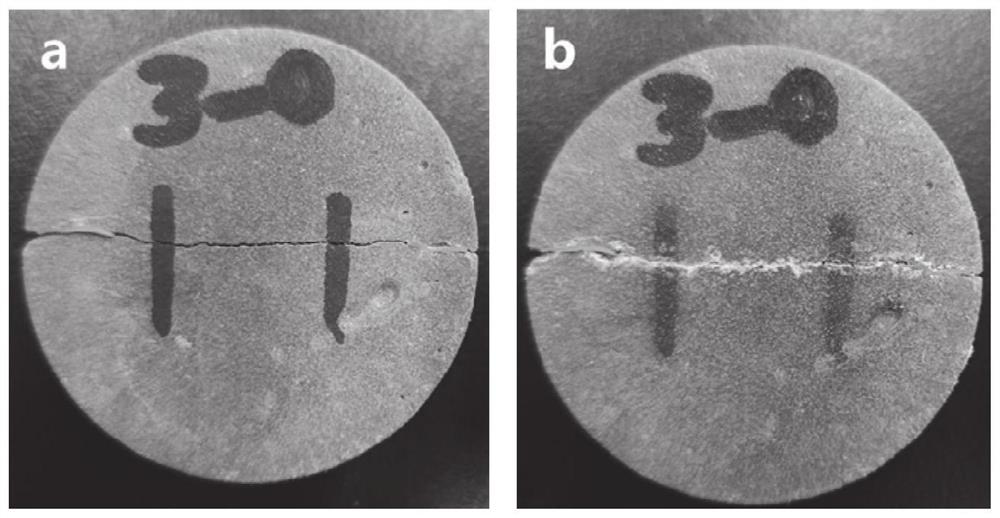

Embodiment 3

[0085] A method for preparing a self-repairing cement-based composite material, comprising the following contents:

[0086] Step 1: Prepare self-healing particles according to the preparation method in Step 1 of Example 1.

[0087] Step 2: Weighing raw materials in parts by mass, including 97.1 parts of cement matrix material, 12 parts of self-repairing particles, and 3 parts of calcium source substrate (calcium chloride).

[0088] The cement matrix material comprises the following components by weight: 30 parts of cement, 20 parts of fly ash, 25 parts of quartz sand, 1 part of PVA fiber, 1 part of water reducer, 0.1 part of thickener, and 20 parts of water.

[0089] Step 3: Put the above-mentioned weighed raw materials into the mixer, and stir them thoroughly according to the order of the preparation methods of the composite materials.

[0090] Step 4: shape the stirred material, and store it in an environment of 95% humidity and 20°C for up to 7 days.

[0091] Step 5: The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com