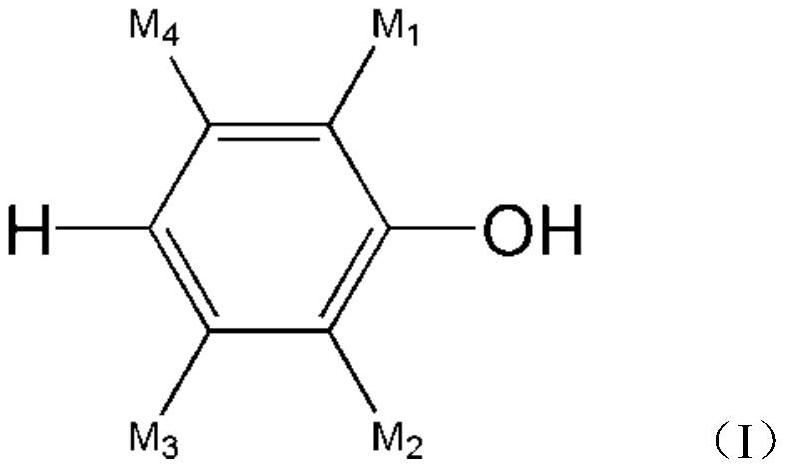

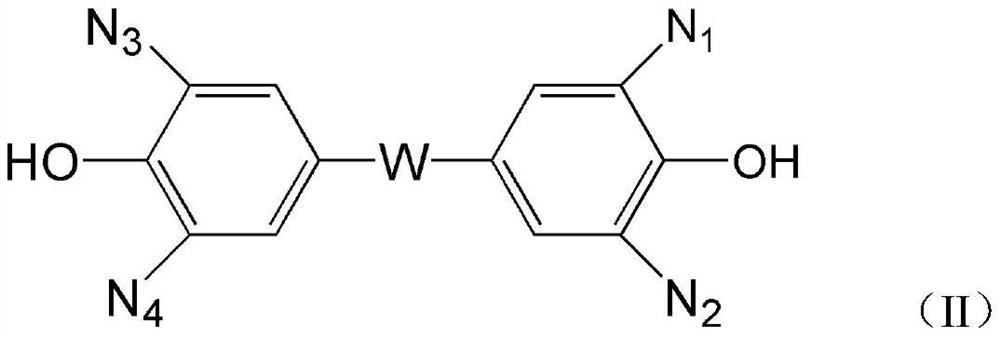

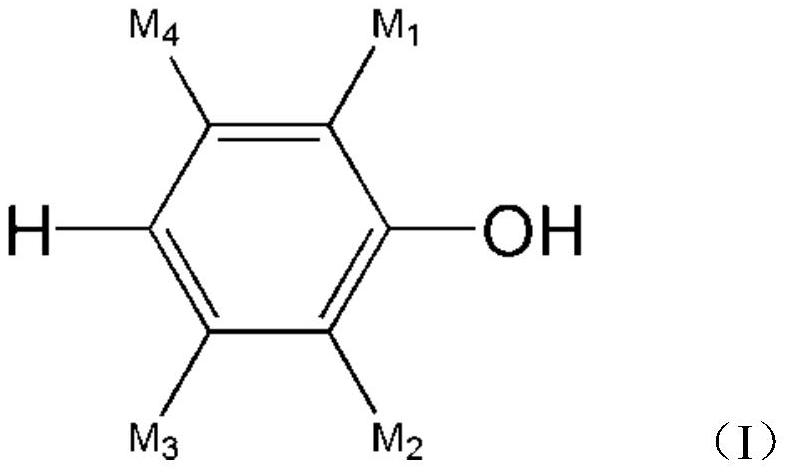

Low-molecular-weight poly (arylene ether) and preparation method thereof

An arylene ether, low molecular weight technology, applied in the field of polyresin, can solve the problems of short preparation process, poor high temperature decomposition resistance, wide molecular weight distribution, etc., and achieve short process, high glass transition temperature and narrow molecular weight distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] (1) Take 10Kg of 2,6-dimethylphenol monomer, 150Kg of toluene and 2Kg of copper ammonium composite catalyst to prepare a solution, inject it into the reaction kettle, start stirring, and pour it into the reaction kettle within the temperature range of 20±5°C Introduce 99.99% oxygen into the reactor, start the oxidative polymerization reaction at 40±2°C, then add 40Kg of 2,6-dimethylphenol into the reactor at a uniform speed within 60 minutes, continue the reaction after the dropwise addition, and take samples online until polymerization The intrinsic viscosity of the product reaches 0.12dl / g, and the polymerization is stopped.

[0091] (2) Add an aqueous solution of copper ion chelating agent to the mixed solution of low molecular weight poly(arylene ether), stir and extract for 15 minutes, then let stand for 20 to 30 minutes, separate and remove the lower aqueous phase. Wherein, the concentration of the aqueous solution of the copper ion chelating agent is 0.1mol / L, an...

Embodiment 2

[0099] (1) Get 10Kg of 1:0.8 molar ratio of 2,6-dimethylphenol monomer and mixed monomer of tetramethylbisphenol A, 150Kg of toluene and 2Kg copper ammonium composite catalyst to prepare solution, inject In the reaction kettle, start stirring, feed 99.99% oxygen into the reaction kettle within the temperature range of 20±5°C, start the oxidative polymerization reaction at 40±2°C, and then add 40Kg of 2, 6 Xylenol, continue to react after the dropwise addition is completed, take samples online for detection until the intrinsic viscosity of the polymerized product reaches 0.09dl / g, then stop the polymerization.

[0100] (2) Add an aqueous solution of copper ion chelating agent to the mixed solution of low molecular weight poly(arylene ether), stir and extract for 15 minutes, then let stand for 20 to 30 minutes, separate and remove the lower aqueous phase. Wherein, the concentration of the aqueous solution of the copper ion chelating agent is 0.1mol / L, and the dosage is 35L.

[...

Embodiment 3

[0108] (1) Take 10Kg of 2,6-dimethylphenol monomer, 150Kg of toluene and 3Kg of copper ammonium composite catalyst to prepare a solution, inject it into the reaction kettle, start stirring, and pour into the reaction kettle within the temperature range of 20±5°C Introduce 99.99% oxygen into the reactor, oxidatively polymerize at 40±2°C, then add 40Kg of 2,6-dimethylphenol to the reactor at a uniform speed within 60 minutes, continue the reaction after the dropwise addition, and take samples online until the polymerization product When the intrinsic viscosity reaches 0.28dl / g, the polymerization is stopped.

[0109] (2) Add an aqueous solution of copper ion chelating agent to the mixed solution of low molecular weight poly(arylene ether), stir and extract for 15 minutes, then let stand for 20 to 30 minutes, separate and remove the lower aqueous phase. Wherein, the concentration of the aqueous solution of the copper ion chelating agent is 0.1mol / L, and the dosage is 52.5L.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com