Reflective heat-insulation lanthanum cerate color paste and preparation method thereof

A technology of lanthanum cerate and color paste, which is used in reflection/signal coatings, pigment pastes, paints containing biocides, etc., can solve problems such as being difficult to industrialize production, and achieve long-lasting antibacterial and antifungal effects, high stability, and high stability. Antibacterial and antifungal effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of reflective and heat-insulating lanthanum cerate color paste in the embodiment includes the following steps: mixing and stirring lanthanum cerate, dispersant, defoamer, and deionized water for pre-dispersion, and pumping it into a sand mill for grinding The lanthanum cerate D (90) is 2.2 μm; the above slurry and anti-settling agent are stirred at 650 rpm in a high-speed disperser, and the pH regulator is added to disperse at a high speed of 450 rpm to obtain a color paste.

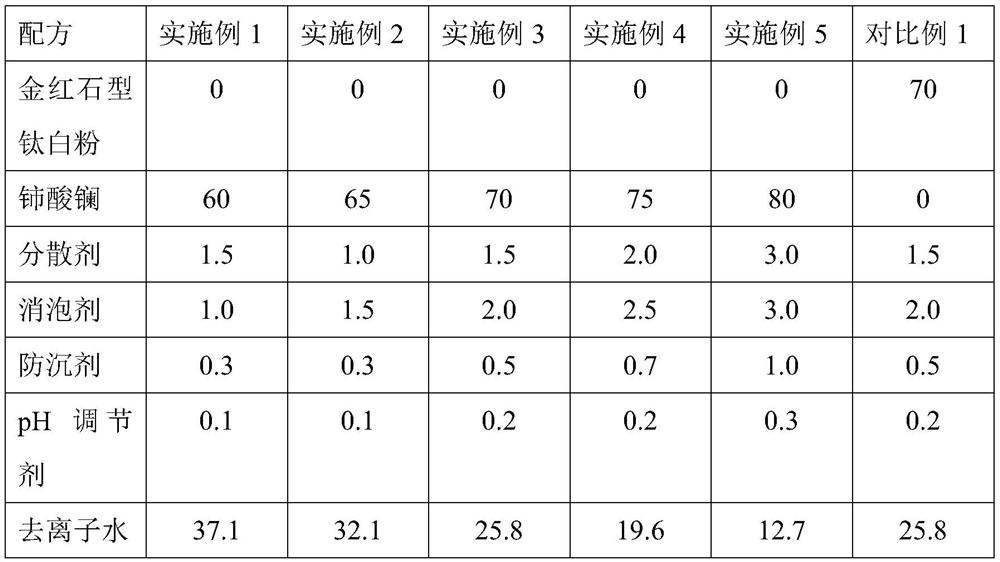

[0041] The raw material proportioning of embodiment 1-5 and comparative example sees the following table:

[0042] Table 1 embodiment 1-5 and comparative example 1 formula table (percentage)

[0043]

[0044] The color paste that embodiment 1-5 and comparative example 1 obtains is tested, and test result is shown in the table below:

[0045] Table 2 embodiment 1-5 and comparative example 1 color paste performance index

[0046] project Example 1 Example 2 ...

Embodiment 6

[0049] The preparation method of the color paste in this example is as follows: 70% of ceric acid lanthanum, 1.5% of dispersant, 2.0% of defoamer, and 25.6% of deionized water are stirred for pre-dispersion according to the mass percentage, and then pumped into a sand mill for grinding until the lanthanum cerate D (90) is 2.2 μm; the above slurry, 0.5% anti-settling agent, and 0.2% inorganic yellow slurry are stirred at a high speed of 650 rpm for 10 minutes in a high-speed disperser, and 0.2% of a pH regulator is added to disperse at a high speed of 450 rpm for 5 minute.

Embodiment 7

[0056] The preparation method of the color paste in this embodiment is as follows: according to the mass percentage, 50% of lanthanum cerate slurry, 4% of rutile titanium dioxide, 4% of filler, 6% of hollow glass microspheres, and 22% of water-based pure acrylic emulsion , auxiliary agent 2%, and water 12% are stirred and mixed at high speed in a disperser to obtain a reflective heat-insulating coating with lanthanum cerate as the main pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com