Steel sleeve joint for connecting steel pipe inner support-retaining structure

An envelope structure and steel sleeve technology, which is applied in the field of steel sleeve joints, can solve the problems that the steel support cannot fully exert the bearing capacity, reduce the rigidity of the flexible end, and the hidden danger of foundation pit engineering, so as to eliminate the adverse effects and reduce the Simple and clear effect of engineering cost and force transmission method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, structure of the present invention, construction process are described further.

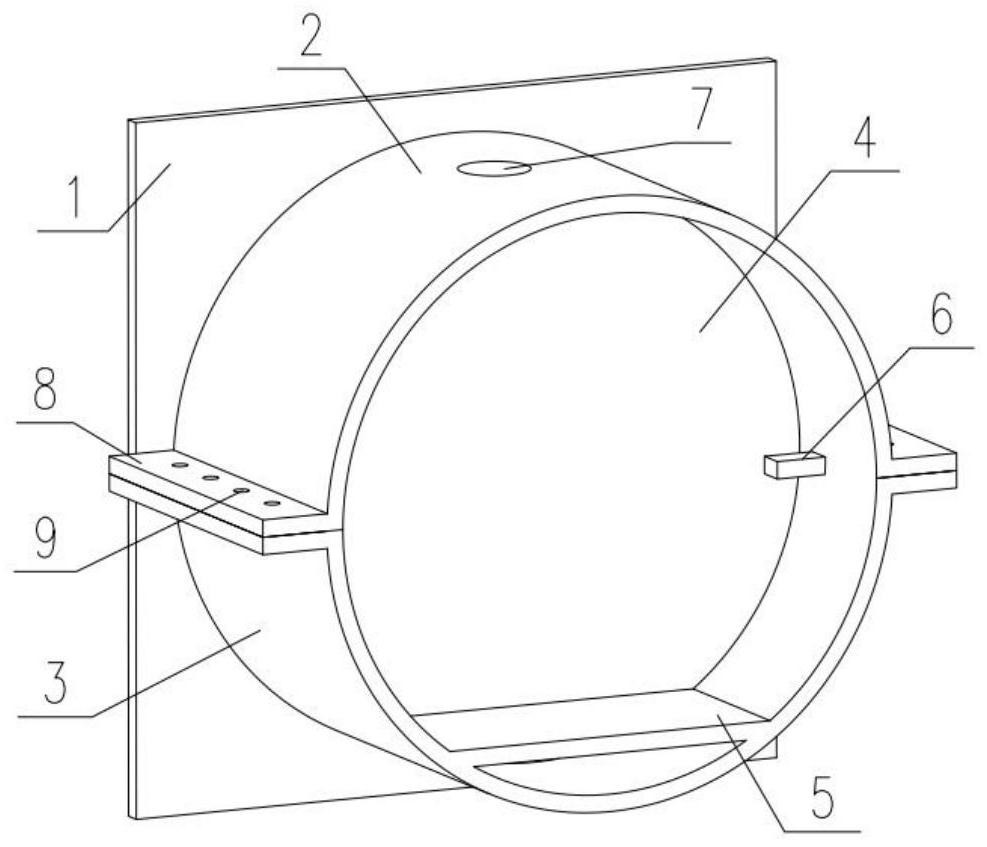

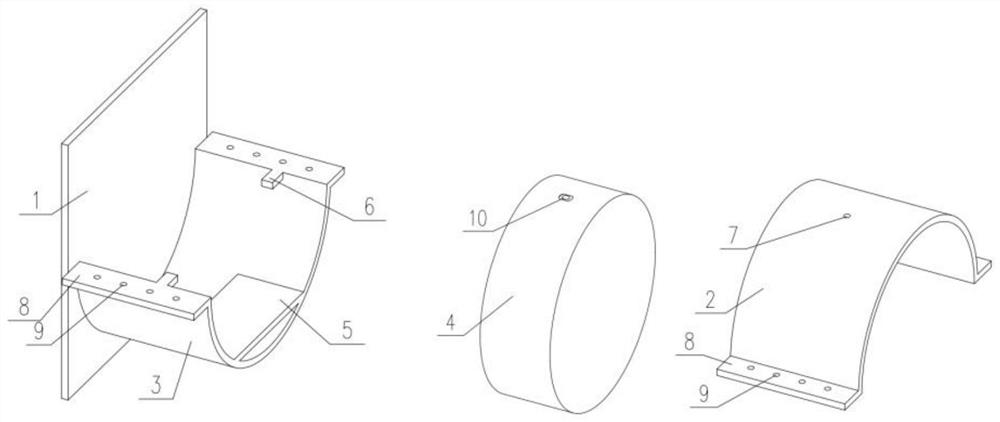

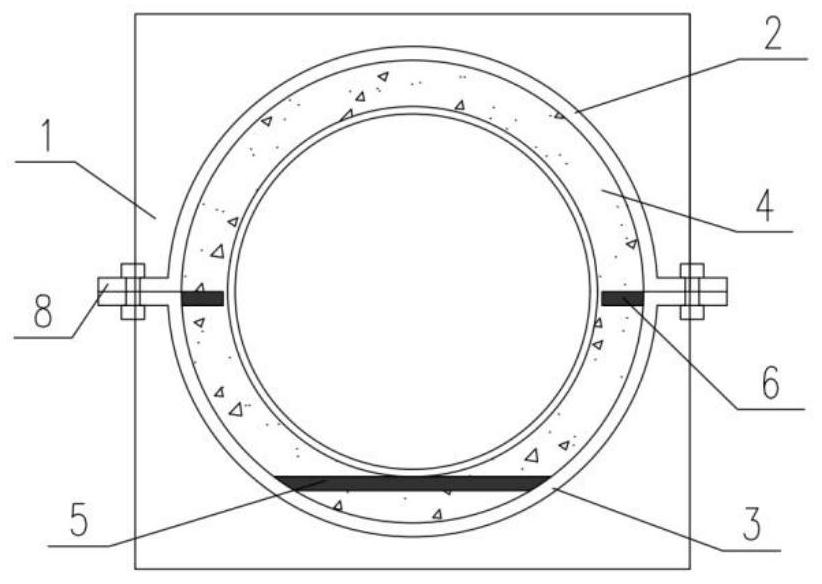

[0020] The invention is a steel sleeve joint connecting the inner support and enclosure structure of the steel pipe, which is a system with simple structure, convenient installation and disassembly, and reasonable stress, and can eliminate the adverse effect of eccentricity on the steel support. As shown in the figure, the main structure is composed of pre-embedded steel plates, steel sleeves 2, 3, molded concrete 4, fixed steel plates 5 and other components. The pre-embedded steel plate 1 is poured in the ground connection wall of the enclosure structure, the lower half sleeve 3 is welded to the pre-embedded steel plate 1, the upper half sleeve 2 and the lower half sleeve 3 are connected by high-strength bolts, and the circular mold bag 4 is placed on the Inside the steel sleeve, after the concrete grouting work is completed, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com