Non-aqueous electrolyte of lithium ion battery and application of non-aqueous electrolyte

A lithium-ion battery, non-aqueous electrolyte technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of damage, instability, uneven SEI film, etc., to promote transmission, enhance the electron-donating effect, Effect of Optimizing High-Temperature Cycle Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

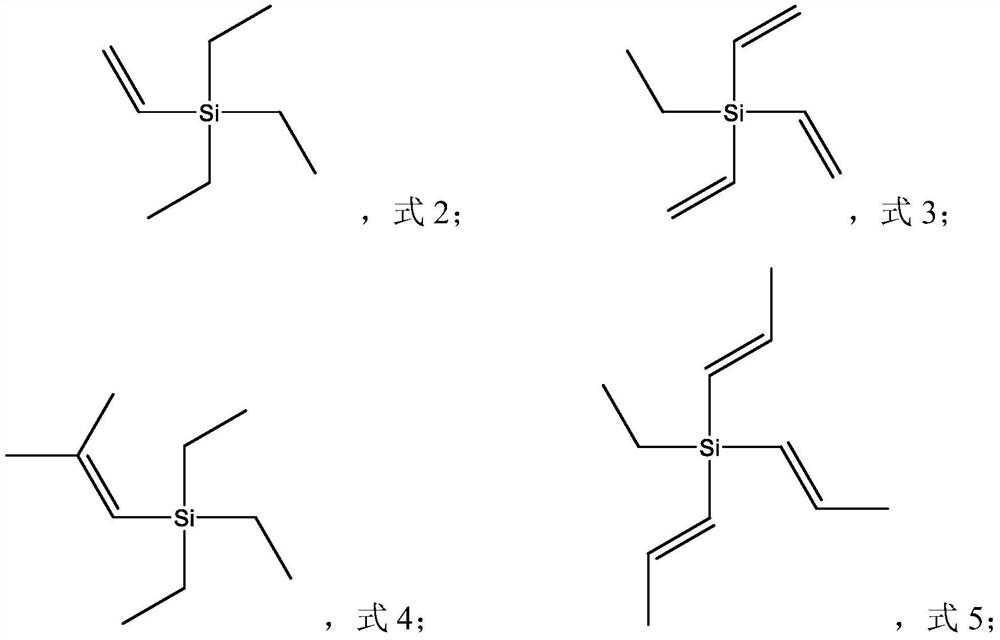

[0066] This embodiment provides a non-aqueous electrolyte solution for lithium-ion batteries. Based on the total mass of the non-aqueous electrolyte solution as 100%, the lithium-ion non-aqueous electrolyte solution includes a fourth compound with a mass percentage of 2.5%. 2.5% of vinylene carbonate, 2.5% of 1,3-propane sultone and 5% of vinyl sulfate additives, lithium salts include lithium hexafluorophosphate with a concentration of 1mol / L and 2.5% by mass Lithium difluorophosphate, 2.5% lithium difluorosulfonyl imide and 5% lithium difluorophosphate oxalate, the balance is a non-aqueous solvent, and the non-aqueous solvent is composed of ethylene carbonate, ethyl methyl carbonate and diethyl carbonate Composition by mass ratio is 3:5:2.

[0067] The preparation method of the lithium-ion battery non-aqueous electrolyte is as follows: the electrolyte is prepared in a glove box, the nitrogen content in the glove box is 99.999%, the actual oxygen content in the glove box is 0....

Embodiment 2

[0075] This embodiment provides a non-aqueous electrolyte solution for lithium-ion batteries. Based on the total mass of the non-aqueous electrolyte solution as 100%, the lithium-ion non-aqueous electrolyte solution includes the fourth compound, 0.025% of vinylene carbonate and 0.025% of 1,3-propane sultone additives, the lithium salt is lithium hexafluorophosphate with a concentration of 0.5mol / L and 5% by mass of lithium difluorophosphate, 5 % lithium bisfluorosulfonyl imide and 10% lithium difluorooxalate phosphate, the balance is a non-aqueous solvent, and the non-aqueous solvent is 3 by mass ratio of ethylene carbonate, ethyl methyl carbonate and diethyl carbonate: 5:2 composition.

[0076] The preparation method of the lithium-ion battery non-aqueous electrolyte is as follows: the electrolyte is prepared in a glove box, the nitrogen content in the glove box is 99.999%, the actual oxygen content in the glove box is 0.1ppm, and the moisture content is 0.1ppm. Based on the...

Embodiment 3

[0079] This embodiment provides a non-aqueous electrolyte solution for lithium-ion batteries. Based on the total mass of the non-aqueous electrolyte solution as 100%, the lithium-ion non-aqueous electrolyte solution includes a fourth compound with a mass percentage of 5%, 5% of vinylene carbonate, 10% of 1,3-propane sultone and 5% of vinyl sulfate additives, the concentration of lithium salt includes 2mol / L lithium hexafluorophosphate and 0.025% by mass Lithium difluorophosphate and 0.025% lithium bisfluorosulfonyl imide, the balance is a non-aqueous solvent, and the non-aqueous solvent is composed of ethylene carbonate, ethyl methyl carbonate and diethyl carbonate in a mass ratio of 3:5:2 .

[0080]The preparation method of the lithium-ion battery non-aqueous electrolyte is as follows: the electrolyte is prepared in a glove box, the nitrogen content in the glove box is 99.999%, the actual oxygen content in the glove box is 0.1ppm, and the moisture content is 0.1ppm. Based on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com