Supporting an optical element

A technology of optical components and components, applied in the direction of optical components, optics, optomechanical equipment, etc., can solve the problem of uneven distribution of impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

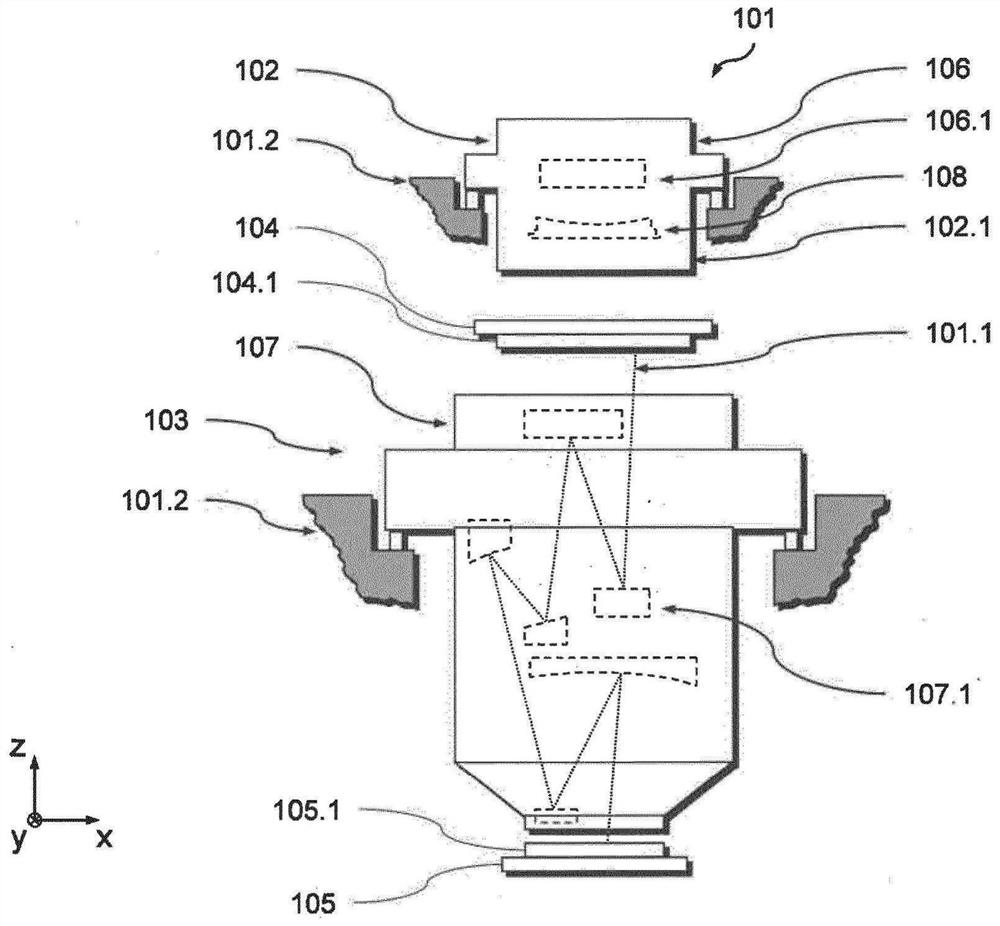

[0090] The following reference Figure 1 to Figure 4 A preferred embodiment of a microlithographic projection exposure apparatus 101 according to the invention is described, comprising a preferred embodiment of the optical arrangement according to the invention. To simplify the following explanations, an x, y, z coordinate system is indicated in the attached drawings, the z direction corresponding to the direction of gravity. It goes without saying that any desired other orientation of the x, y, z coordinate system can be selected in a further configuration.

[0091] figure 1 is a schematic, not to scale representation of a projection exposure apparatus 101 used in a microlithography process for producing semiconductor components. The projection exposure apparatus 101 comprises an illumination device 102 and a projection device 103 . The projection device 103 is designed to transfer an image of the structure of the mask 104.1 arranged in the mask unit 104 onto the substrate...

no. 2 example

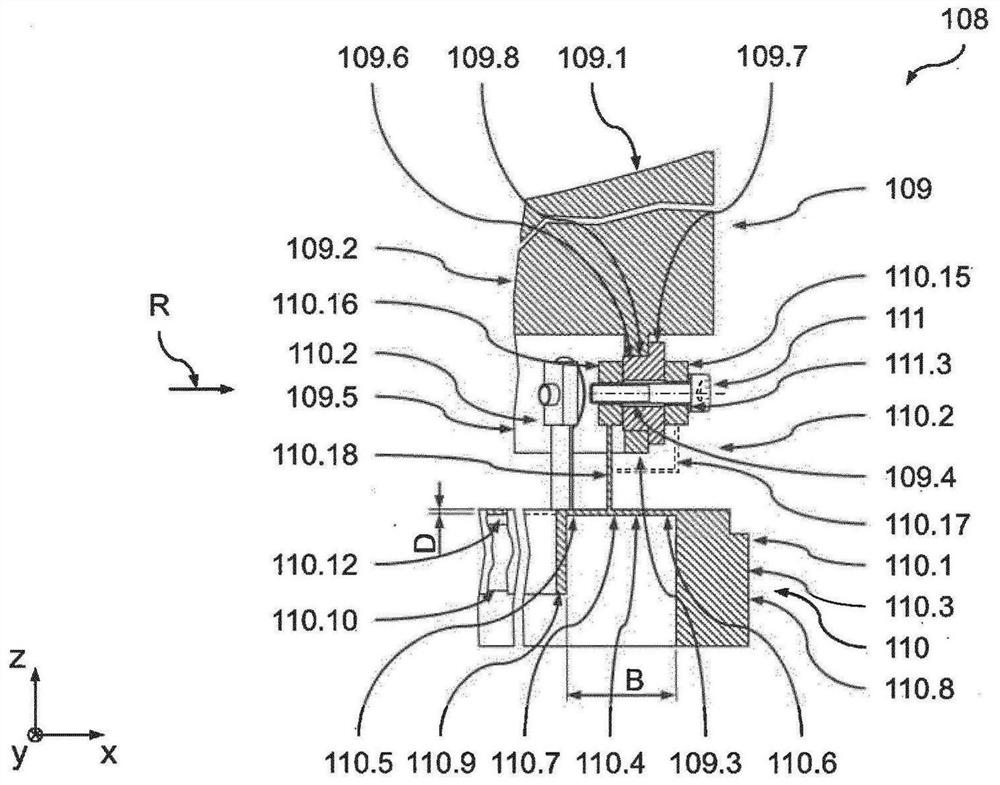

[0163] The following reference figure 1 , figure 2 ,and Figure 5 to Figure 7 A further preferred embodiment of the arrangement 208 according to the invention which can be used instead of the arrangement 108 in the imaging device 101 is illustrated. Arrangement 208 corresponds in its basic design and function to that from Figure 2 to Figure 4 108, so only the differences will be discussed here. In particular, identical parts are provided with identical reference numerals, whereas similar parts are provided with reference numerals incremented by the value 100. Unless stated otherwise below, reference is made to the above statements in relation to the first embodiment as to the features, functions, and advantages of these components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com