Screen printing plate required by silk-screen printing

A technology of screen printing and screen printing, applied in printing, printing plate preparation, etc., can solve problems such as easy to cause pollution, difficult to remove, and easy physical damage to the resin film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

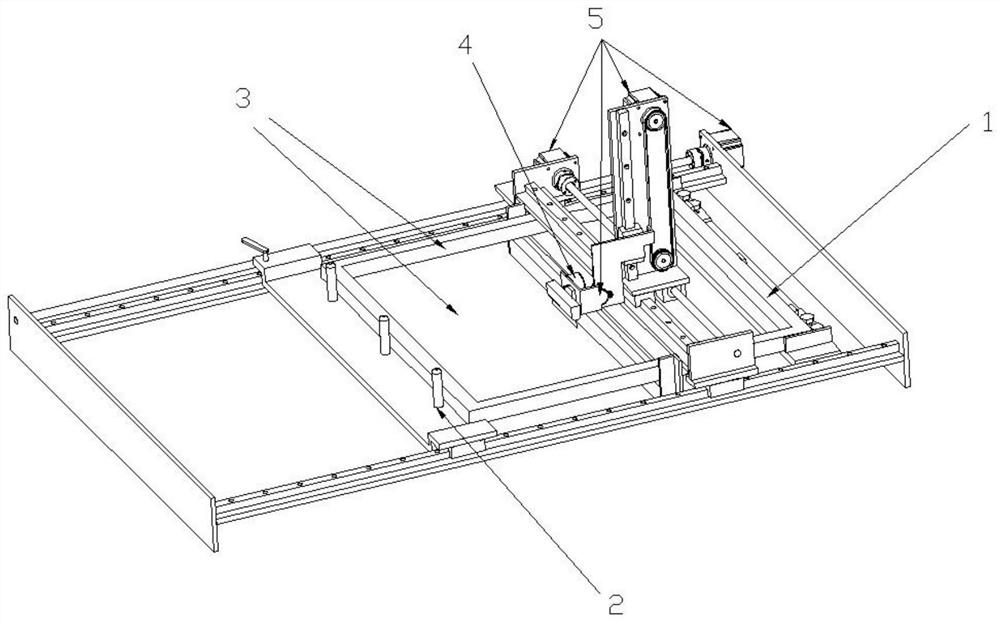

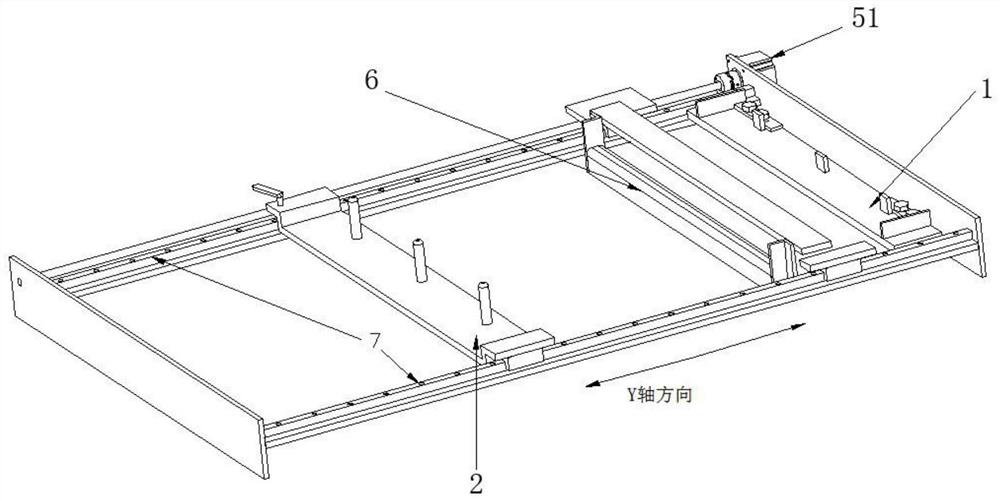

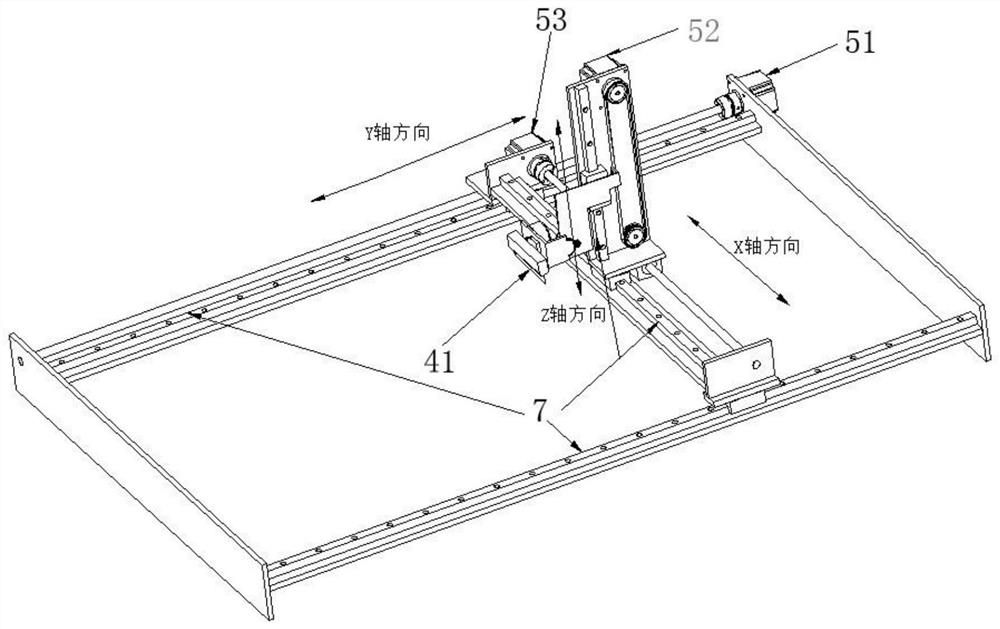

[0055] like Figure 1 to Figure 13 Shown, the required screen printing plate of screen printing of the present invention is made through the following steps:

[0056] Step 1. First make omentum yarn, there are two methods:

[0057] 1) Use the unwinding and unwinding equipment to lay out the mesh, coat the non-printing surface of the mesh 32 with an adhesive layer, and then coat the thermoplastic resin on the adhesive layer to form a thin film through the laminating equipment. This layer of film is called omentum 33, and this omentum 33 completely seals the non-printing surface, and the semi-finished product made of mesh yarn 32 and this omentum 33 is called omentum yarn below.

[0058] 2) The waxy material is directly coated onto the non-printing surface of the mesh 32 to form a layer of film through the film coating equipment, and the layer of film is called the omentum 33, and the omentum 33 completely covers the non-printing surface. Sealing, the semi-finished product tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com