Porous hydrogel sponge as well as preparation method and application thereof

A porous hydrogel and sponge technology, applied in pharmaceutical formulations, bandages, drug delivery, etc., can solve the problems of unfavorable material biocompatibility, high hemostatic performance, unsatisfactory hemostatic effect of dry hydrogels, lack of uniform pore structure and pore size and other issues, to achieve excellent biocompatibility and degradation performance, improve water absorption and hemostatic efficiency, and mild pore-making conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

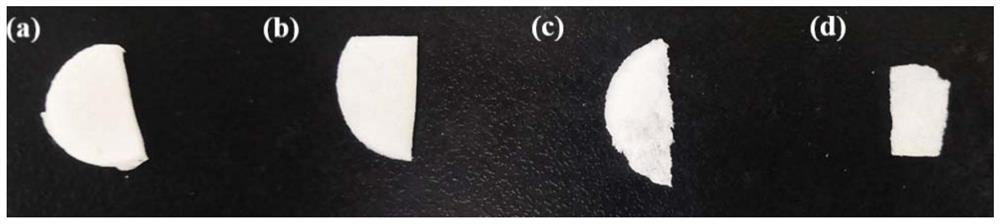

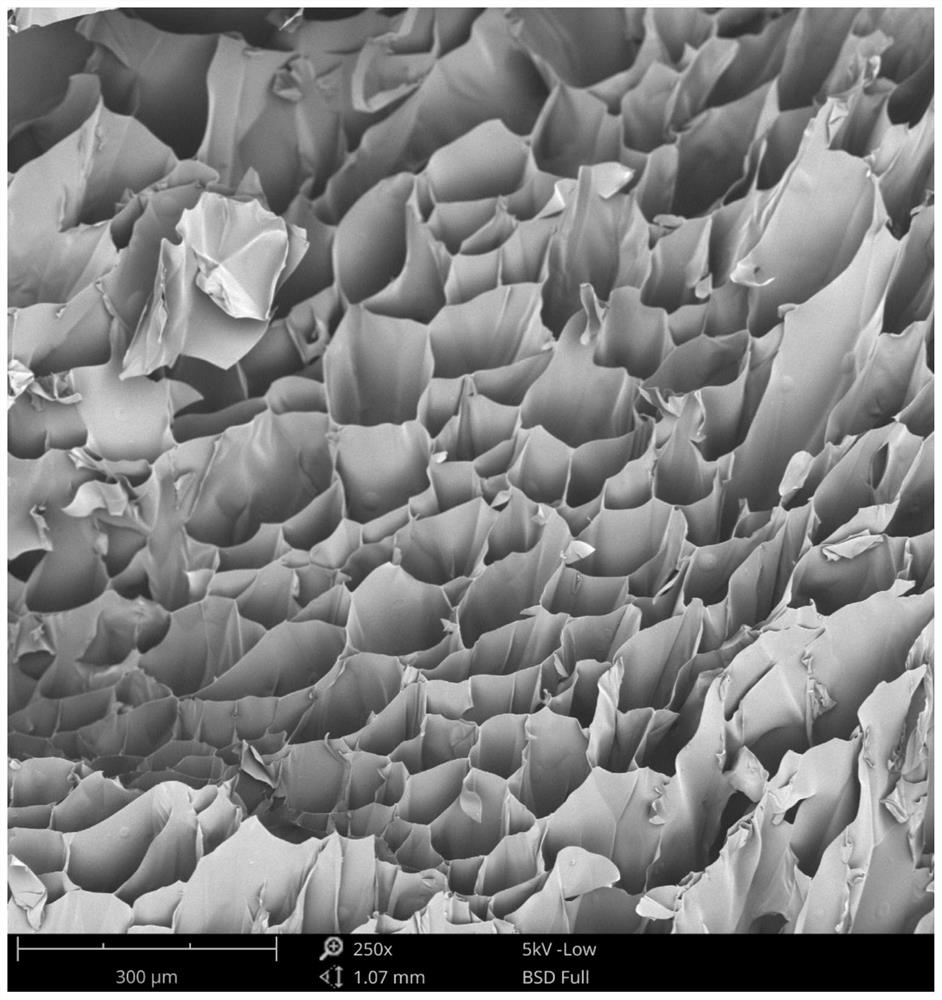

Embodiment 1

[0046] This embodiment has prepared a kind of porous hydrogel sponge, and specific process is:

[0047] S1: Take 0.3 g of gelatin microspheres with a particle size of about 100 μm and place them in a polytetrafluoroethylene mold, and gently tap the mold to make the gelatin microspheres tightly packed and the surface smooth;

[0048] S2: Inject ethanol solution into the stacked gelatin microspheres, inject about 1 mL of ethanol solution with a volume concentration of 80% per gram of gelatin microspheres;

[0049] S3: Move the mold to an oven at 70°C for 8 minutes;

[0050] S4: taking out the mold and freeze-drying to obtain a template of gelatin microspheres bonded to each other, and the microspheres adjacent to each other are slightly bonded at the interface to form a template of gelatin microspheres bonded to each other;

[0051]S5: Put the gelatin microsphere template in step S4 into 1 mL of 2% double-bonded hyaluronic acid containing 0.2% 2-hydroxyl-4'-(2-hydroxyethoxyl)-2...

Embodiment 2

[0056] This embodiment has prepared a kind of porous hydrogel sponge, and specific process is:

[0057] S1: Take 0.3 g of gelatin microspheres with a particle size of about 230 μm and place them in a polytetrafluoroethylene mold, and gently tap the mold to make the gelatin microspheres tightly packed and the surface smooth;

[0058] S2: Inject ethanol solution into the stacked gelatin microspheres, inject about 1 mL of ethanol solution with a volume concentration of 80% per gram of gelatin microspheres;

[0059] S3: Move the mold to an oven at 70°C for 8 minutes;

[0060] S4: taking out the mold and freeze-drying to obtain gelatin microsphere templates bonded to each other, and the microspheres adjacent to each other are slightly bonded at the interface to form gelatin microsphere templates bonded to each other;

[0061] S5: Put the gelatin microsphere template in step S4 into 1 mL of 2% double-bonded hyaluronic acid containing 0.2% 2-hydroxyl-4'-(2-hydroxyethoxyl)-2-methylpr...

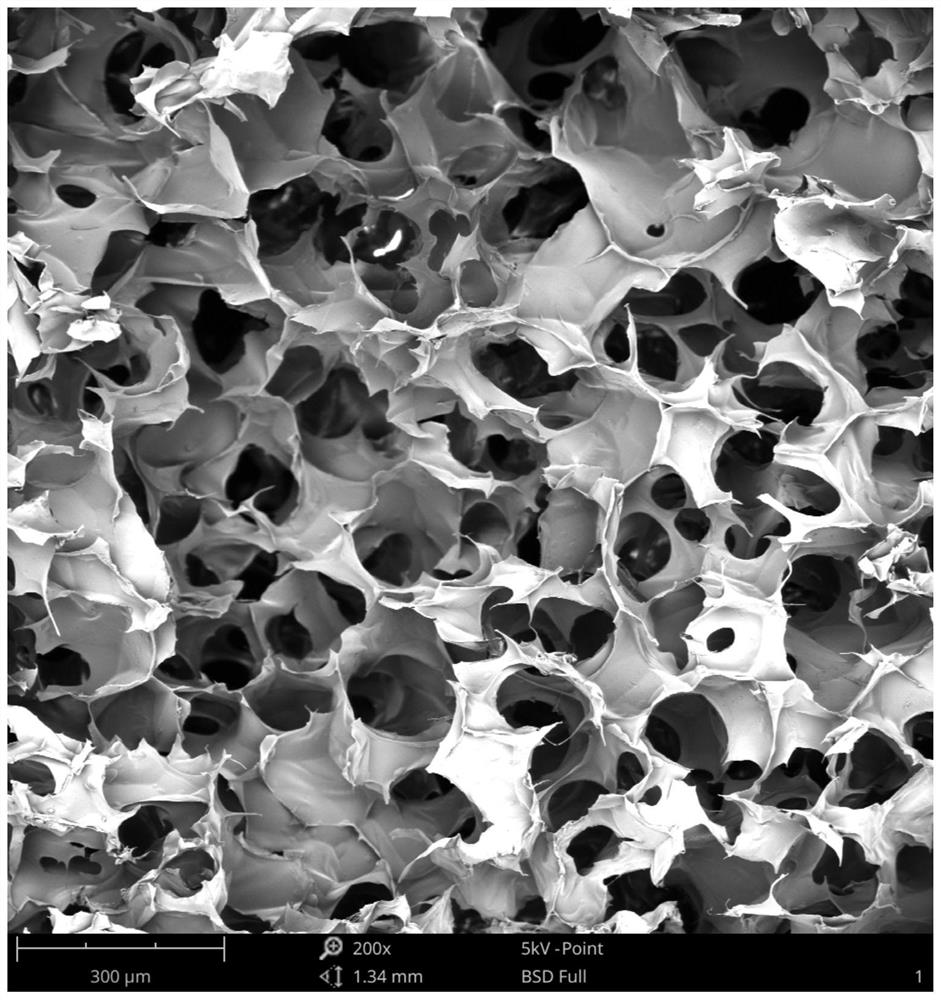

Embodiment 3

[0066] This embodiment has prepared a kind of porous hydrogel sponge, and specific process is:

[0067] S1: Take 0.3 g of gelatin microspheres with a particle size of about 300 μm and place them in a polytetrafluoroethylene mold, and gently tap the mold to make the gelatin microspheres tightly packed and the surface smooth;

[0068] S2: Inject ethanol solution into the stacked gelatin microspheres, inject about 1 mL of ethanol solution with a volume concentration of 80% per gram of gelatin microspheres;

[0069] S3: Move the mold to an oven at 70°C for 8 minutes;

[0070] S4: taking out the mold and freeze-drying to obtain gelatin microsphere templates bonded to each other, and the microspheres adjacent to each other are slightly bonded at the interface to form gelatin microsphere templates bonded to each other;

[0071] S5: Put the gelatin microsphere template in step (4) into 1 mL of 2% double bond containing 0.2% 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com