Electrowetting-driven variable-focus liquid lens with configurable initial focal length

A technology of liquid lens and focal length, which is applied in lenses, instruments, optics, etc., can solve the problem that the initial focal length cannot be changed, and achieve the effect of satisfying response time, flexible size, and focal length change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

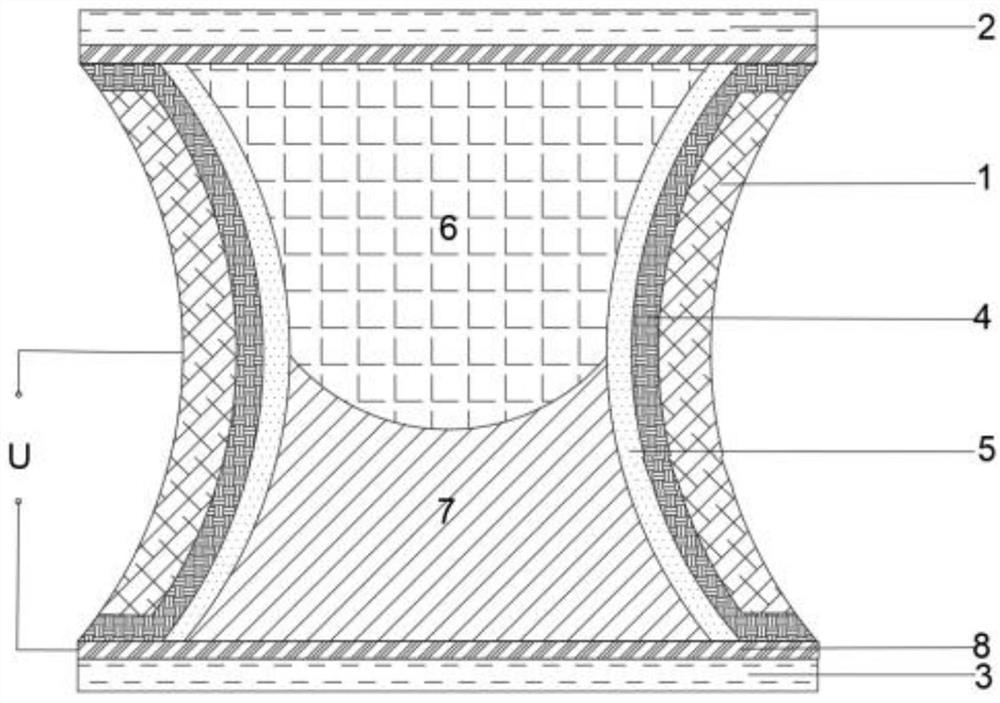

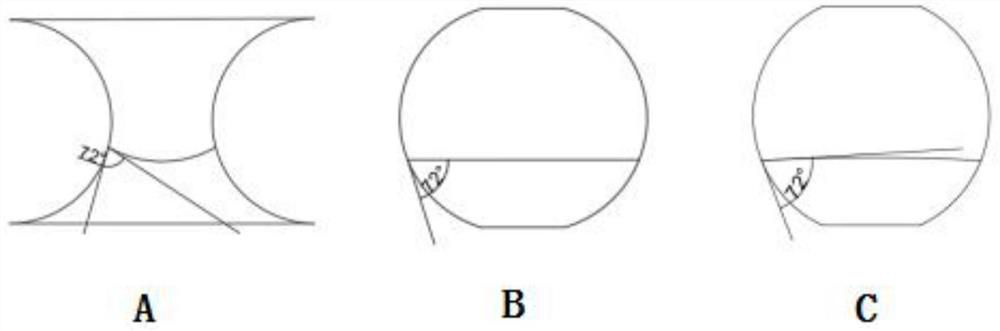

Embodiment 1

[0035] like Figure 4 As shown, an electro-wetting driven variable liquid lens with configurable initial focal length, its conductive inner core body 1 is a spherical surface formed by rotating a circle or a part of a circle, and its internal structure is the same as the above-mentioned structure. First make the spherical conductive inner core body 1, the conductive inner core body 1 is made of conductor copper, first make a spherical mold protruding outward (you can also make a spherical mold concave inward), then melt the conductive copper, and pour the liquid copper into the mold Among them, a complete conductive inner core body 1 can be formed after the liquid copper is cooled. Then, evenly coat the inner wall of the main body of the conductive inner core with a 3-micron thick epoxy resin insulating coating, and then coat the insulating layer with a layer of polyolefin hydrophobic layer to play the role of hydrophobic modification. The lower part of the conductive inner c...

Embodiment 2

[0037] like Figure 5 As shown, an electro-wetting driven variable liquid lens with configurable initial focal length, its conductive inner core body 1 is an ellipse or an ellipsoid formed by rotating part of an ellipse, and its internal structure is the same as the above-mentioned structure. Firstly, the ellipsoid conductive inner core body 1 is made, the conductive inner core body 1 is made of conductive aluminum, and the conductive inner core body protruding outward is made, processed by a lathe, and an aluminum conductive inner core body 1 is processed by a lathe, and then the conductive inner core body 1 is processed in the conductive The inner wall of the inner core body 1 is evenly coated with a layer of 3 micron thick alumina ceramic insulation coating, and after the insulating layer is coated, a layer of polycarbonate hydrophobic layer is coated to play the role of hydrophobic modification. The lower part of the conductive inner core body 1 is sealed with ITO conductive...

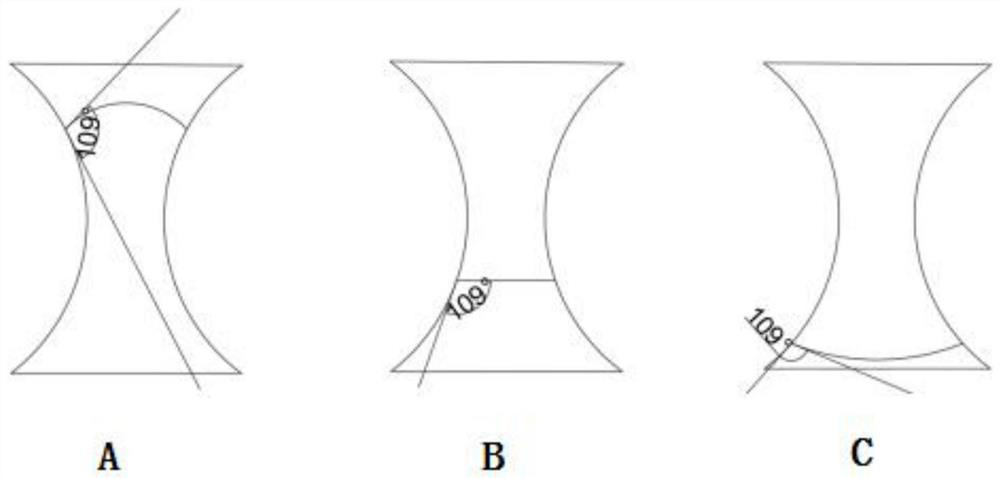

Embodiment 3

[0039] like Image 6 As shown, an electro-wetting driven variable liquid lens with configurable initial focal length, its conductive inner core body 1 is a hyperbola or a hyperboloid formed by rotating a part of a hyperbola, and its internal structure is the same as the above-mentioned structure. Firstly, the hyperboloid conductive inner core main body 1 is made, and the conductive inner core main body 1 adopts conductive iron. Divide the conductive inner core main body 1 into upper and lower m pieces and make them separately, process m pieces of small conductive inner core main bodies respectively with a lathe using the method of embodiment 2, and then coat ceramic polymer insulating coating, and separately coat the insulating layer to make the insulation The layer is more evenly applied. When coating the insulating layer on each small piece of conductive inner core body, the connection of the conductive inner core body can be coated with an insulating layer or not coated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com