Diaphragm of lithium ion battery, and preparation method and application thereof

A technology of lithium-ion batteries and lithium batteries, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., to suppress battery deformation, improve the ability to resist external damage, increase the rate and cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

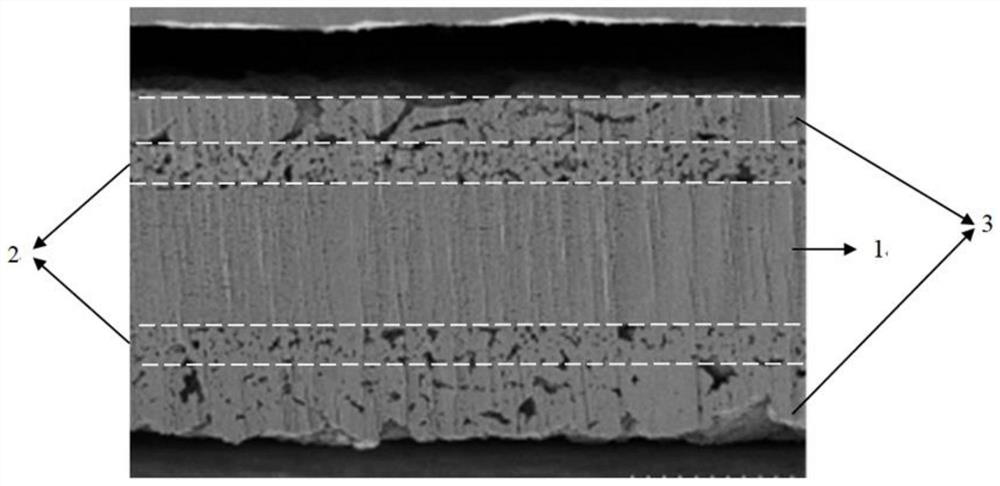

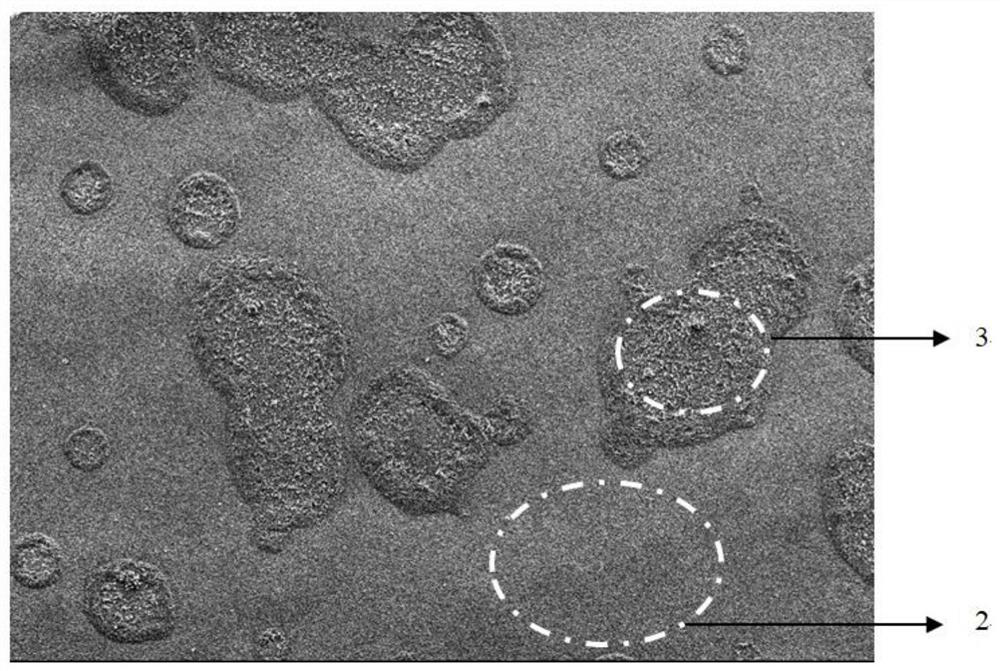

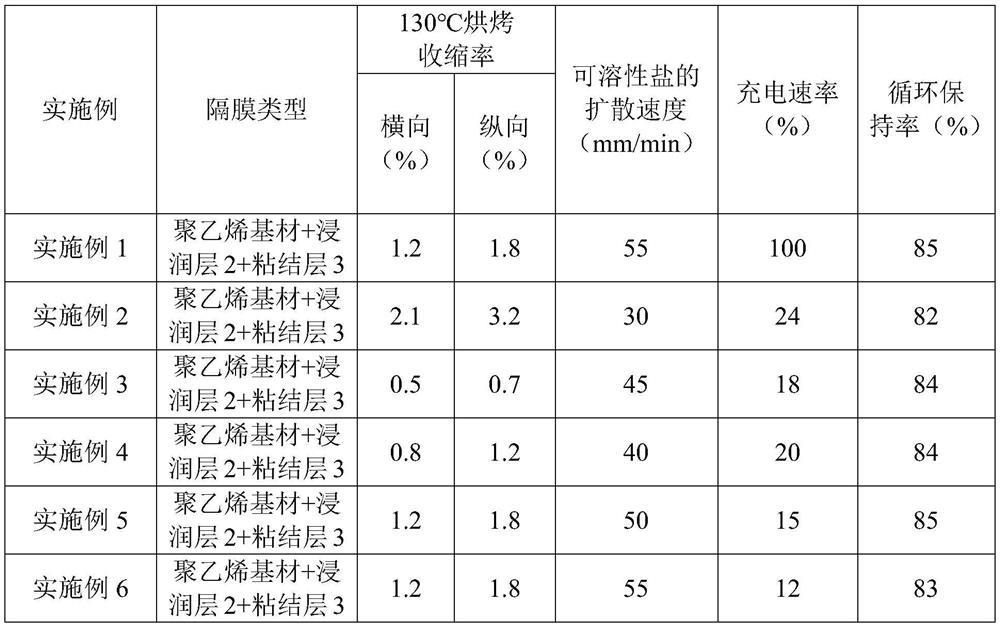

[0049] This embodiment provides a separator for a lithium-ion battery. The separator substrate 1 has a thickness of 9 μm and a tortuosity of 20%; the thickness of the wetting layer 2 is 3 μm, and the diffusion rate of the soluble salt in the wetting layer 2 is 55 mm / min; Layer 3 coverage was 65%.

[0050] figure 1 It is a cross-sectional SEM test diagram of the separator of the lithium-ion battery provided in Example 1.

[0051] figure 2 It is a plane SEM test picture of the separator of the lithium-ion battery provided in Example 1.

Embodiment 2

[0053] This embodiment provides a separator for a lithium-ion battery. The separator substrate 1 has a thickness of 5 μm and a tortuosity of 18%; the thickness of the wetting layer 2 is 3.5 μm, and the diffusion rate of the soluble salt in the wetting layer 2 is 30 mm / min; The coverage of junction layer 3 is 50%.

Embodiment 3

[0055] This embodiment provides a diaphragm for a lithium-ion battery. The diaphragm substrate 1 has a thickness of 15 μm and a tortuosity of 16%; the thickness of the wetting layer 2 is 5 μm, and the diffusion rate of the soluble salt in the wetting layer 2 is 45 mm / min; Layer 3 coverage was 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com