Water-soluble binder, preparation method of binder and method for preparing parts

A water-soluble binder and parts technology, which is applied in the field of metal powder injection molding, can solve the problem that the metal powder injection molding process cannot be well applied, and achieves advantages of popularization and large-scale production, cost-free pollution, and good extrusion. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

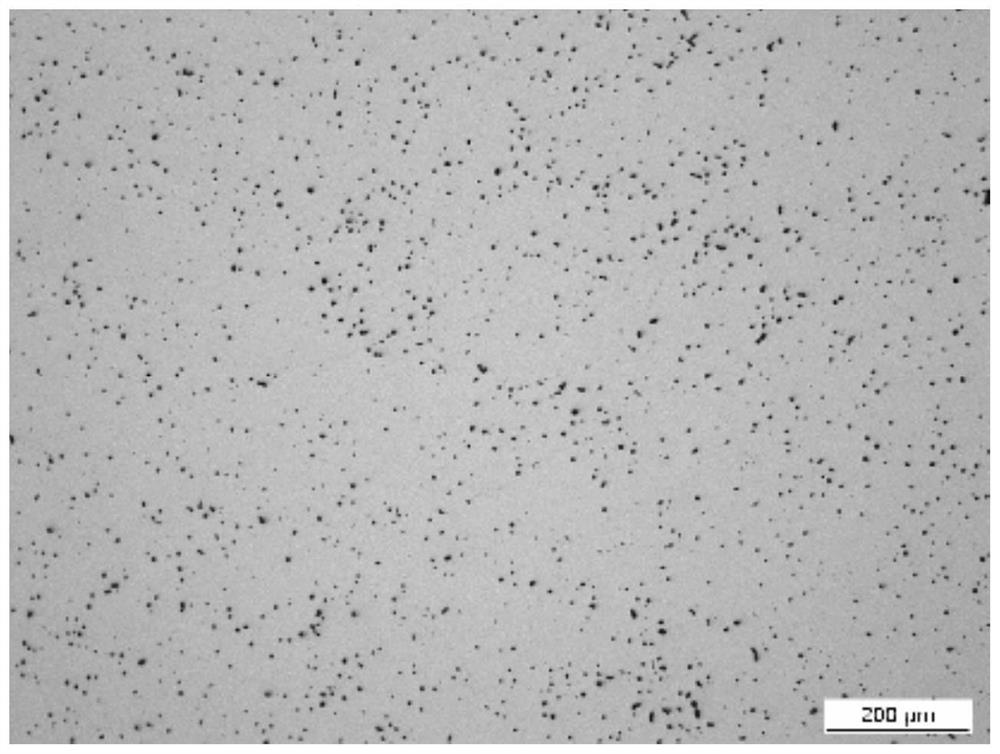

[0033] Such as figure 1 Shown is the first preferred embodiment of the present invention. The metal powder in this embodiment is 316 stainless steel powder, the antioxidant is BHT (2,6-di-tert-butyl-4-methylphenol), and the framework material is HDPE (high-density polyethylene).

[0034] In terms of mass percentage, the water-soluble binder in this embodiment includes 30% PEG1000, 40% PEG2000, 15% POM, 5% SA, 1% BHT and 9% HDPE. The method for preparing the water-soluble binder in this embodiment is to first melt 15% POM, then add 30% PEG1000, 40% PEG2000, 5% SA, 1% BHT, 9% HDPE to the melted POM and wait for all After the raw materials are melted and mixed evenly, the water-soluble binder is prepared.

[0035] The method for preparing parts using the water-soluble binder of this embodiment includes the following steps in turn: S1 Mixing and feeding: According to the mass percentage, binder: 316 stainless steel powder=7:100 ratio is mixed evenly in the molten state ; S2 Mol...

Embodiment 2

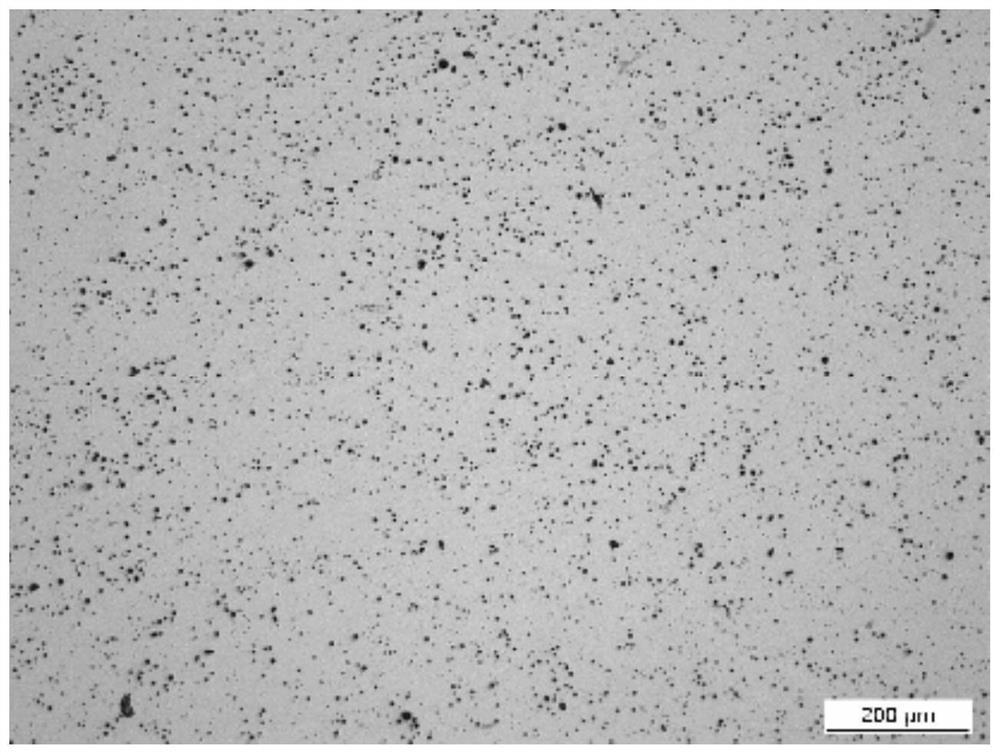

[0037] Such as figure 2 Shown is the second preferred embodiment of the present invention. The metal powder in this embodiment is 316 stainless steel powder, the antioxidant is BHA (butyl hydroxyanisole), and the skeleton material is LDPE (low-density polyethylene, also known as high-pressure polyethylene).

[0038]The difference between this embodiment and the above-mentioned embodiment 1 is: 1) there are differences in the mass percentages of the components in the water-soluble binder, specifically, in terms of mass percentage, the binder of this embodiment includes 35% PEG1000, 35% % PEG2000, 15% POM, 6% SA, 2% BHA and 7% LDPE.

[0039] 2) There is a difference in the ratio of binder and stainless steel powder in the mixed feed. Specifically, the binder and stainless steel powder are mixed evenly at a ratio of 12:100. The bending strength of the tested part is 6.0MPa, and the strength of the green body of the part is higher than that of wax Base feed part strength increa...

Embodiment 3

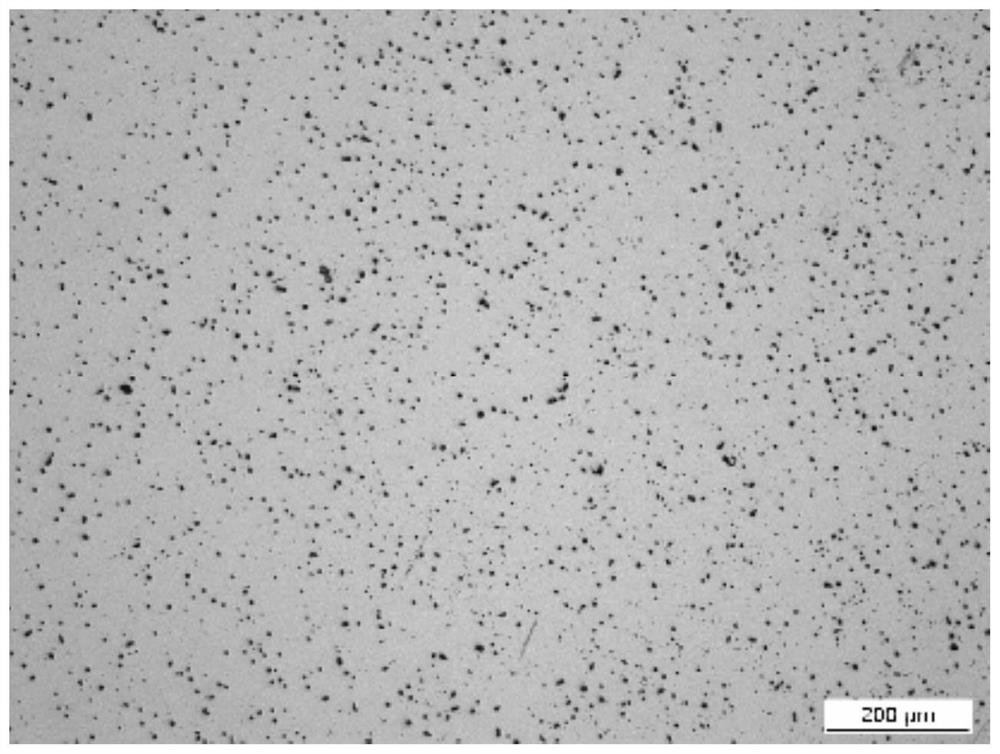

[0043] Such as image 3 Shown is the 3rd preferred embodiment of the present invention.

[0044] The antioxidant is TBHQ (tert-butylhydroquinone), and the skeleton material is PP (polypropylene).

[0045] The difference between this embodiment and the above-mentioned embodiment 1 is: 1) there are differences in the mass percentages of the components in the water-soluble binder, specifically, in terms of mass percentage, the binder in this embodiment includes 35% PEG1000, 39% PEG2000, 15% POM, 5% SA, 1% TBHQ and 5% PP;

[0046] 2) There is a difference in the ratio of binder and stainless steel powder in the mixed feed. Specifically, the binder and stainless steel powder are mixed evenly at a ratio of 10:100. The bending strength of the tested part is 5.8MPa, and the strength of the green body of the part is higher than that of wax Base feed part strength increased by about 5%;

[0047] 3) There is a difference in the rotational speed of the agitator in the degreasing treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com