Electric arc additive and deep cold rolling forming composite manufacturing device and method

A technology for manufacturing equipment and rolling deformation, which is applied in the direction of household refrigeration equipment, refrigeration equipment isolation, cooling fluid circulation equipment, etc., can solve the problems of increased liquid nitrogen consumption, poor temperature control accuracy, and high failure rate, and achieve maintenance Uniformity and consistency, ensuring uniformity, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

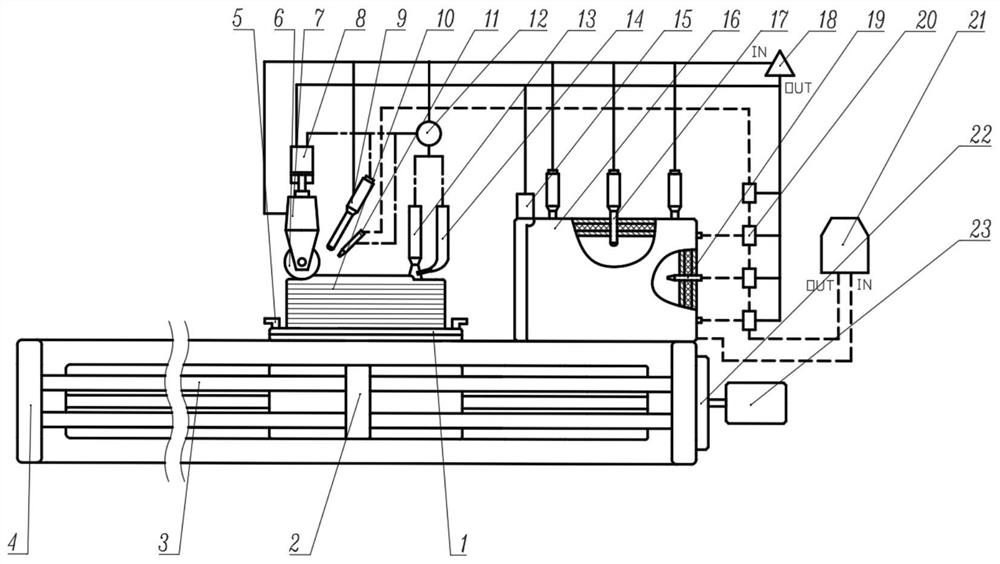

[0041] figure 1It is a schematic diagram of the structure of the composite manufacturing device of arc additive material and cryogenic rolling forming, figure 1 In the figure, the solid line connected to the controller is the signal line; the dotted line is the hydraulic pipeline; the dotted line is the mechanical structure between each device and the motion mechanism. The composite manufacturing device of arc additive material and cryogenic rolling forming in this embodiment includes a base 4 and a workbench 2. The workbench 2 is set on the base 4 and can move horizontally on the base 4.

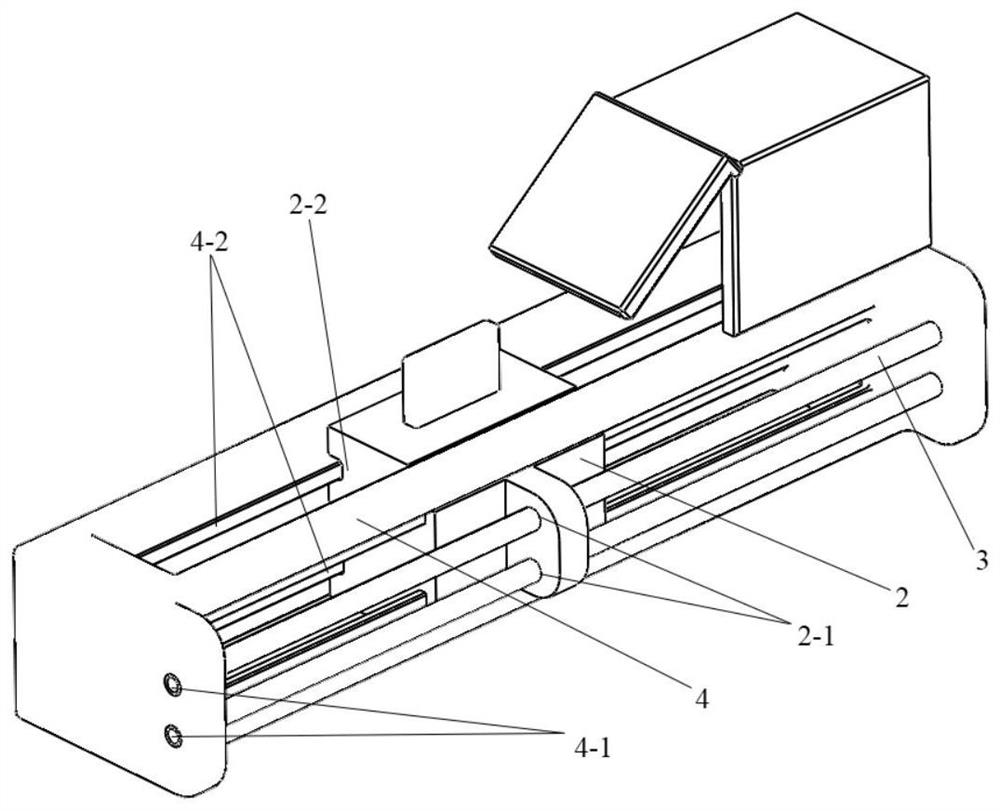

[0042] refer to figure 2 , one side of the workbench 2 is provided with a lug 2-1, the other side is provided with a groove 2-2, a screw rod 3 is provided between the two ends of the base 4, and the two ends of the base 4 are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com