Hydrocarbon fuel reforming medium-temperature purification hydrogen production method and device and fuel cell energy supply system

A technology for hydrocarbon fuel and hydrogen production equipment, which is used in hydrocarbon fuel reforming medium-temperature purification and hydrogen production equipment, fuel cell energy supply system, and hydrocarbon fuel reforming medium-temperature purification and hydrogen production field, which can solve the problem and the energy supply system to generate electricity. Efficiency drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

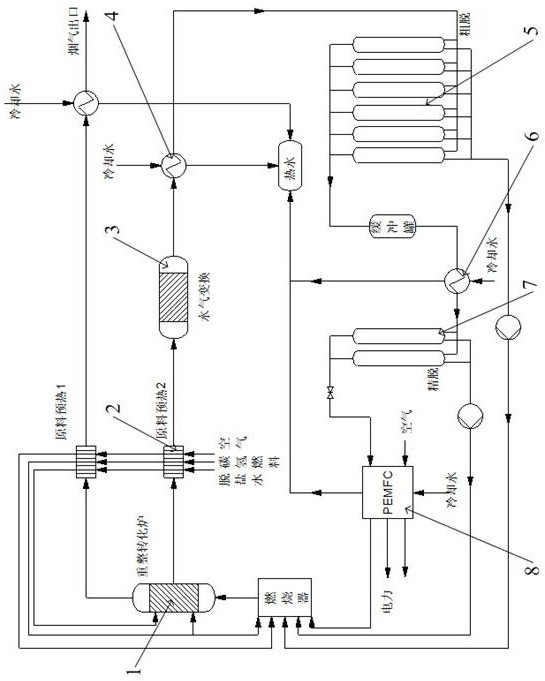

[0139] PEMFC integrated energy supply system using industrial coal gas as raw material

[0140] Raw gas pressure: 2.0MPaG, raw gas temperature 216°C, combined efficiency of power generation and heat supply 2kW

[0141] The raw material gas comes from the hydrogen-rich gas of a coal-water slurry gasifier in a factory. After water-gas shift, it enters the purification, desulfurization and decarbonization process from the industrial production measuring line under the operating conditions of 2.0MPaG pressure and 216℃ temperature.

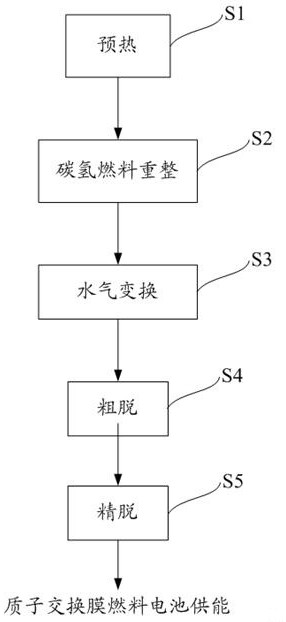

[0142] The two-stage purification method of medium temperature pressure swing adsorption + medium temperature variable pressure swing adsorption is adopted to realize the supply of fuel hydrogen for PEMFC and realize the combined efficiency of 2kW power generation and heat supply.

[0143] The first stage of coarse desorption adopts medium temperature pressure swing adsorption 8-6-1 process, that is, 8 adsorption towers - 6 times of pressure equalizati...

Embodiment 2

[0145] Steam Reforming PEMFC Combined Heat and Power System with Civil Natural Gas as Raw Material

[0146] Raw gas pressure: 0.002MPaG, raw gas temperature 25°C, combined efficiency of power generation and heat supply 100kW

[0147] The raw material gas comes from civil natural gas. After pressurization and reforming waste heat preheating, it is reformed with steam to produce hydrogen-rich gas. After water-gas shift, it enters the purification process.

[0148] The two-stage purification method of medium temperature and pressure swing adsorption + medium temperature and pressure swing adsorption is adopted to realize the supply of fuel hydrogen for PEMFC and realize the combined efficiency of 100kW power generation and heat supply.

[0149] The first stage of coarse desorption adopts medium temperature (vacuum) pressure swing adsorption 6-3-1 process, that is, 6 adsorption towers - 3 times of pressure equalization - 1 adsorption, coupled with a vacuum process, filled with hyd...

Embodiment 3

[0151] Hydrogen-doped natural gas steam reforming PEMFC combined heat and power system

[0152] Raw gas pressure: 0.002MPaG, raw gas temperature 25°C, combined efficiency of power generation and heat supply 30kW

[0153] The two-stage purification method of medium temperature pressure swing adsorption + medium temperature pressure swing adsorption is adopted to supply fuel hydrogen to PEMFC and achieve a combined efficiency of 30kW power generation and heat supply.

[0154] The raw material gas comes from hydrogen-doped natural gas. After pressurization and reforming waste heat preheating, it is reformed with steam to produce hydrogen-rich gas. After water-gas shift, it enters the purification process.

[0155] The first stage of rough removal adopts medium temperature pressure swing adsorption 7-4-1 process, that is, 7 adsorption towers-4 times of equal pressure-1 adsorption, coupled with parallel discharge, low-pressure steam flushing, nitrogen cleaning and vacuuming process...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap